Advanced control system for enhanced operation of oscillating combustion in combustors

a control system and advanced technology, applied in the direction of combustion types, combustion using lumps and pulverizing fuel, lighting and heating apparatus, etc., can solve the problems of complex operation on top of controlling the additional oxidant flow, frequent shut-down and start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

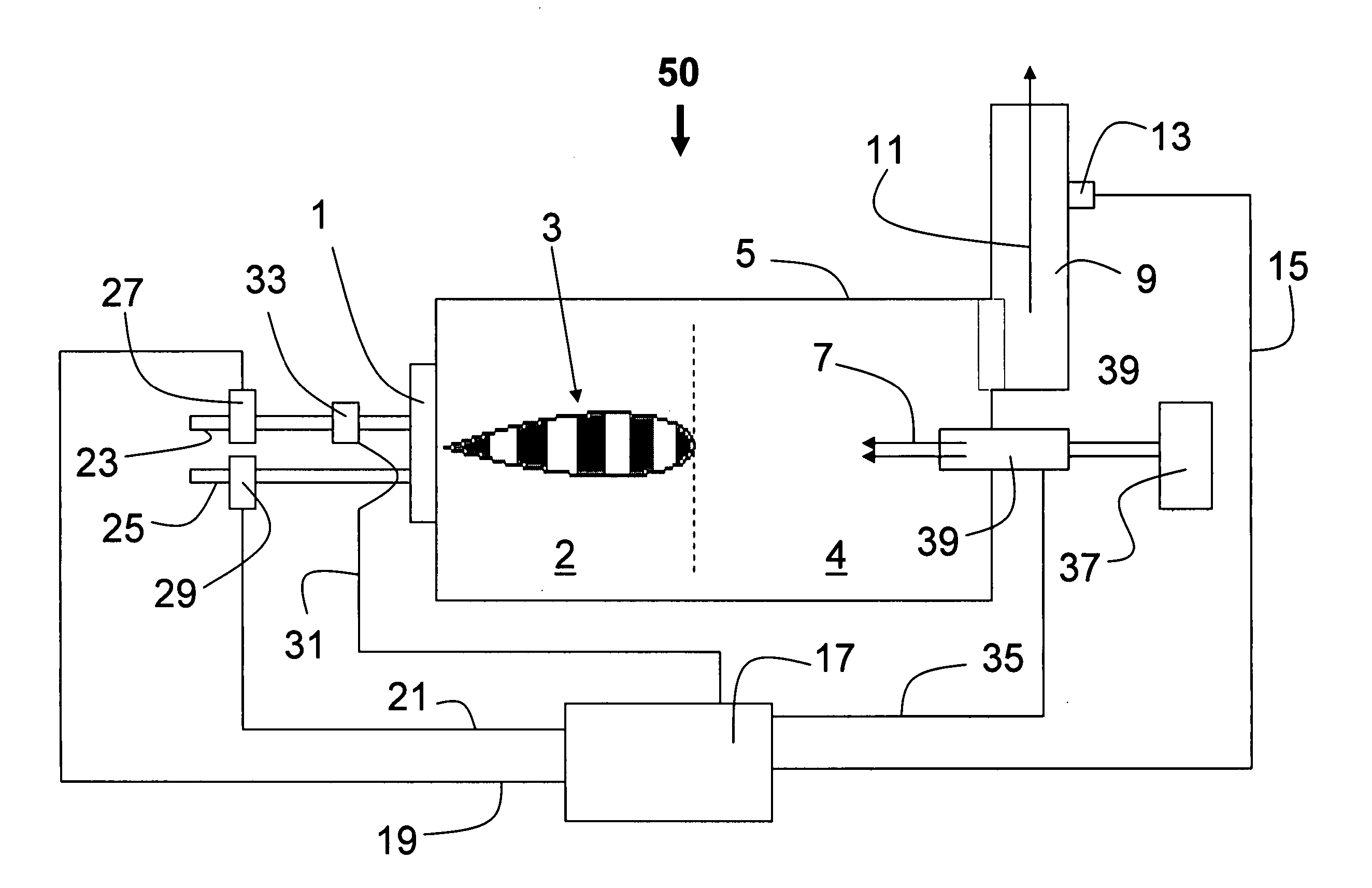

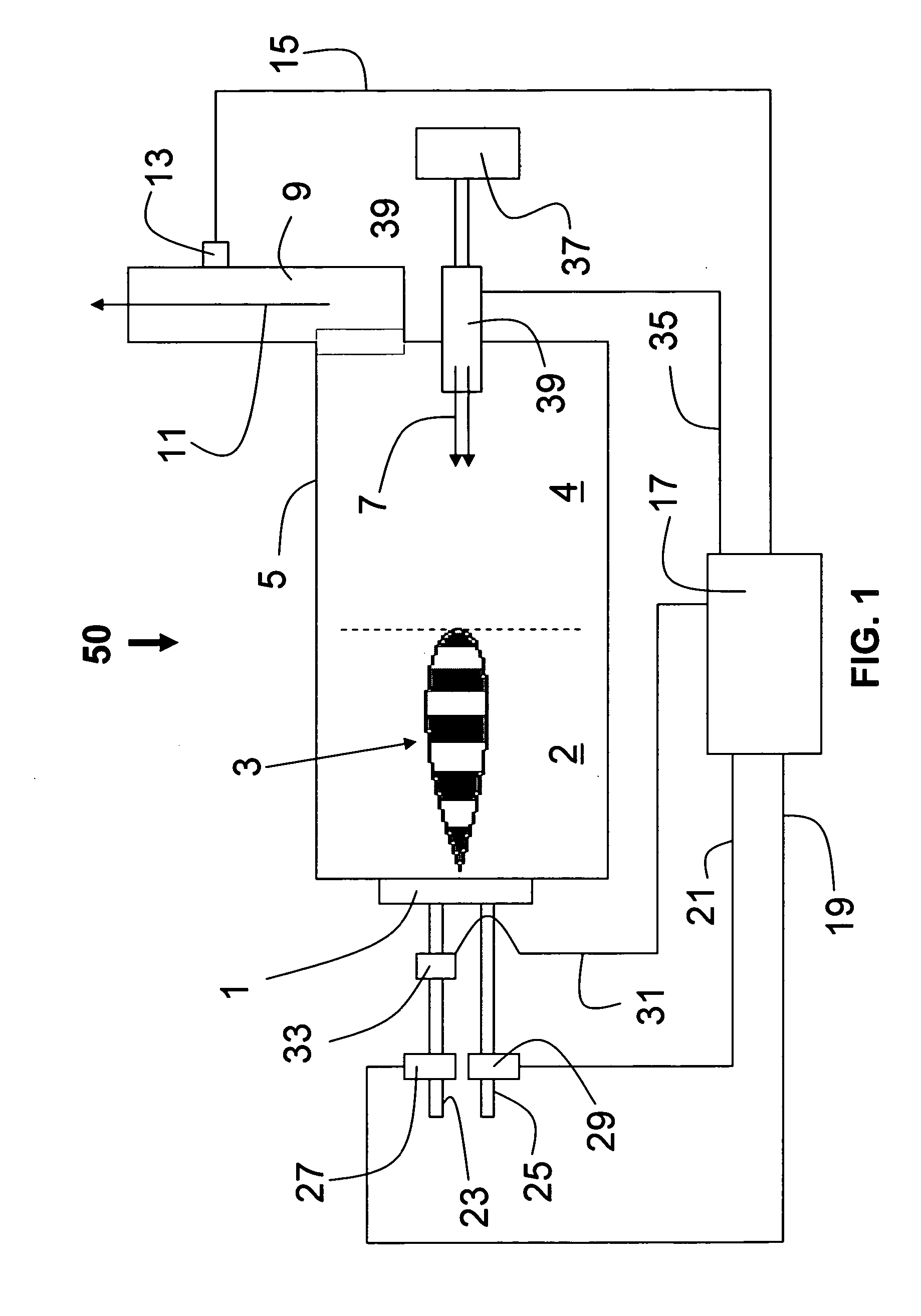

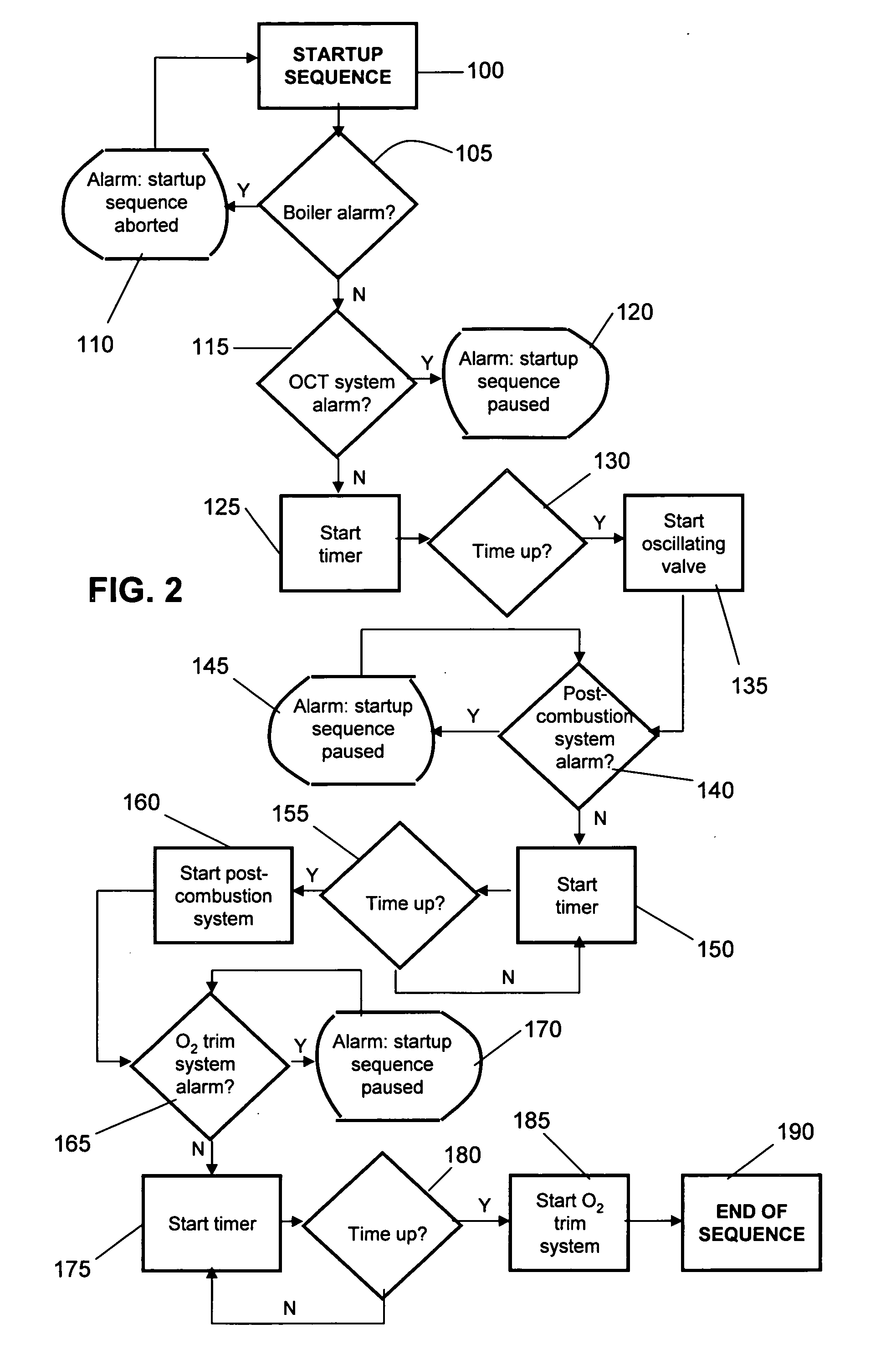

[0024] In order to solve the above mentioned problems, the present invention proposes an innovative system and method for operating and controlling the oscillating combustion technology in combustors subject to demanding operating constraints, such as industrial boilers and process heaters. An improvement of the present invention is directed to performing safe startups and shutdowns with a controller. One purpose is to integrate an innovative oscillating combustion control scheme to the existing process in order to allow a safe operation of this process at any time and / or to adjust the various control parameters in order to maintain optimal or satisfactory NOx (and optionally CO) reduction and process efficiency.

[0025] The proposed invention can be applied to any industrial application involving the use of at least one burner utilizing oscillating combustion, but is more especially suited for industrial boilers and process heaters utilizing oscillating combustion. Suitable oscillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com