Variable input radiant heater

a radiant heater and variable input technology, applied in the direction of combustion types, domestic stoves or ranges, combustion failure safes, etc., can solve the problems of only two distinct operating inputs for two-stage burners, limited dual regulation, and only coarse control of varying demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

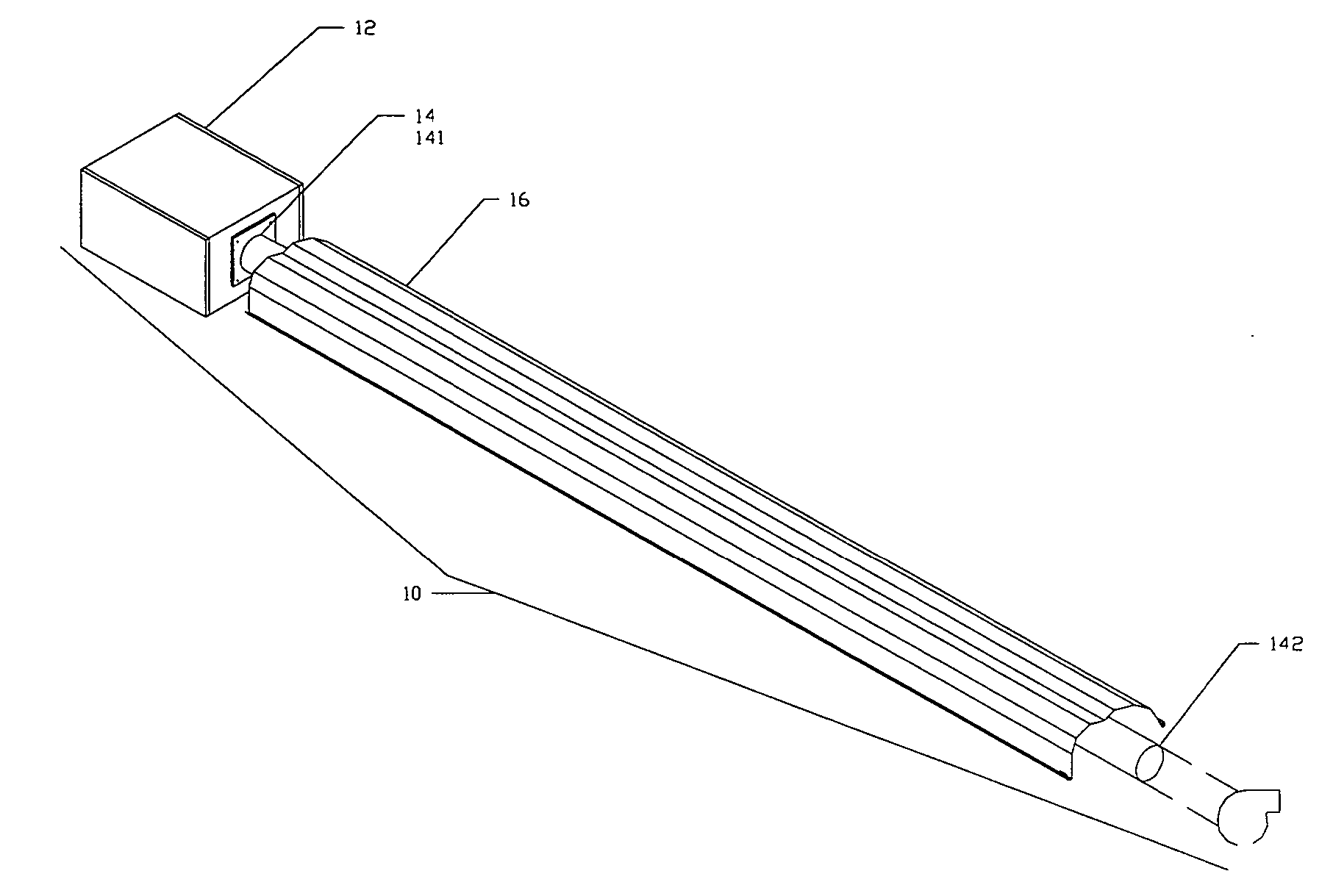

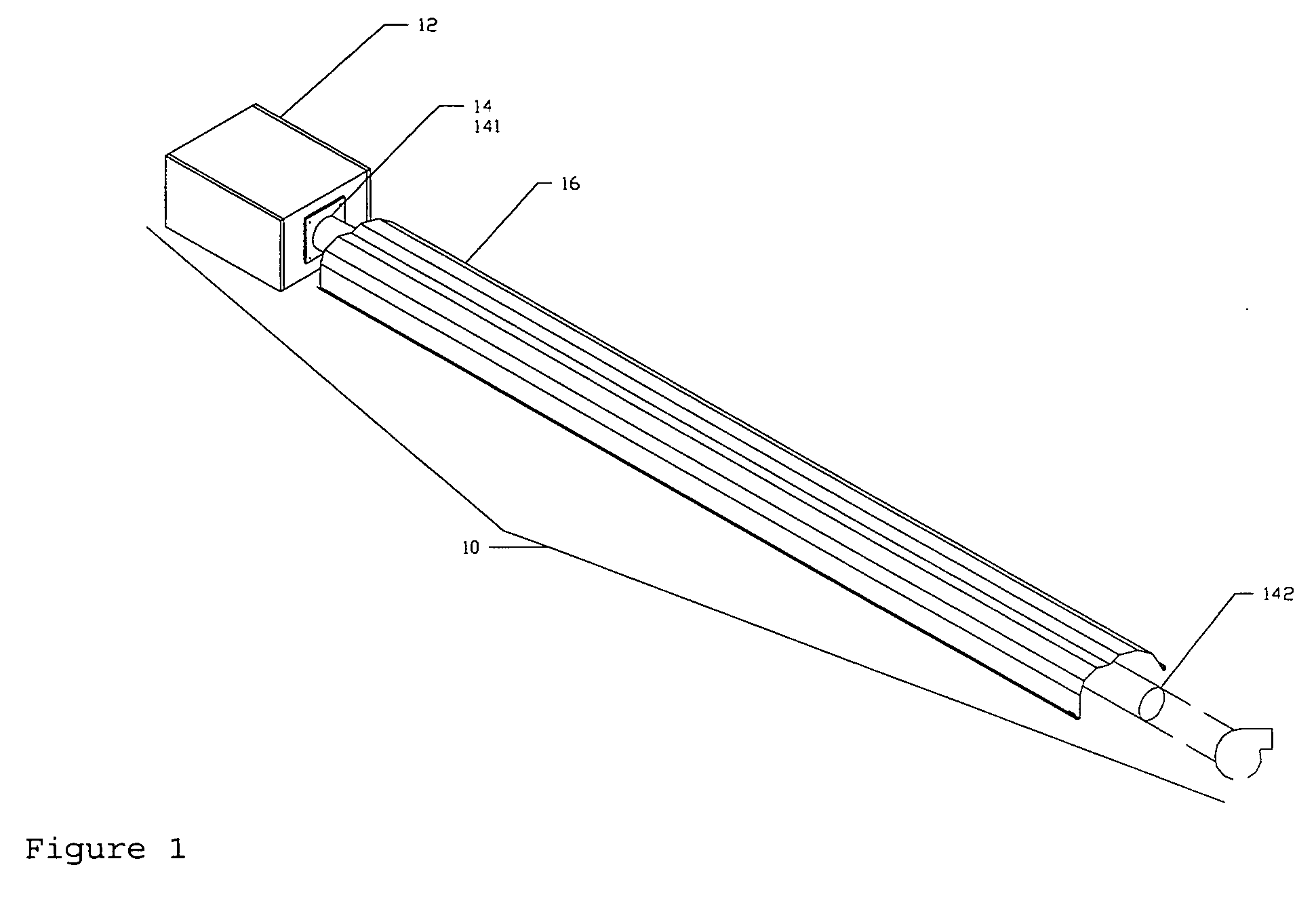

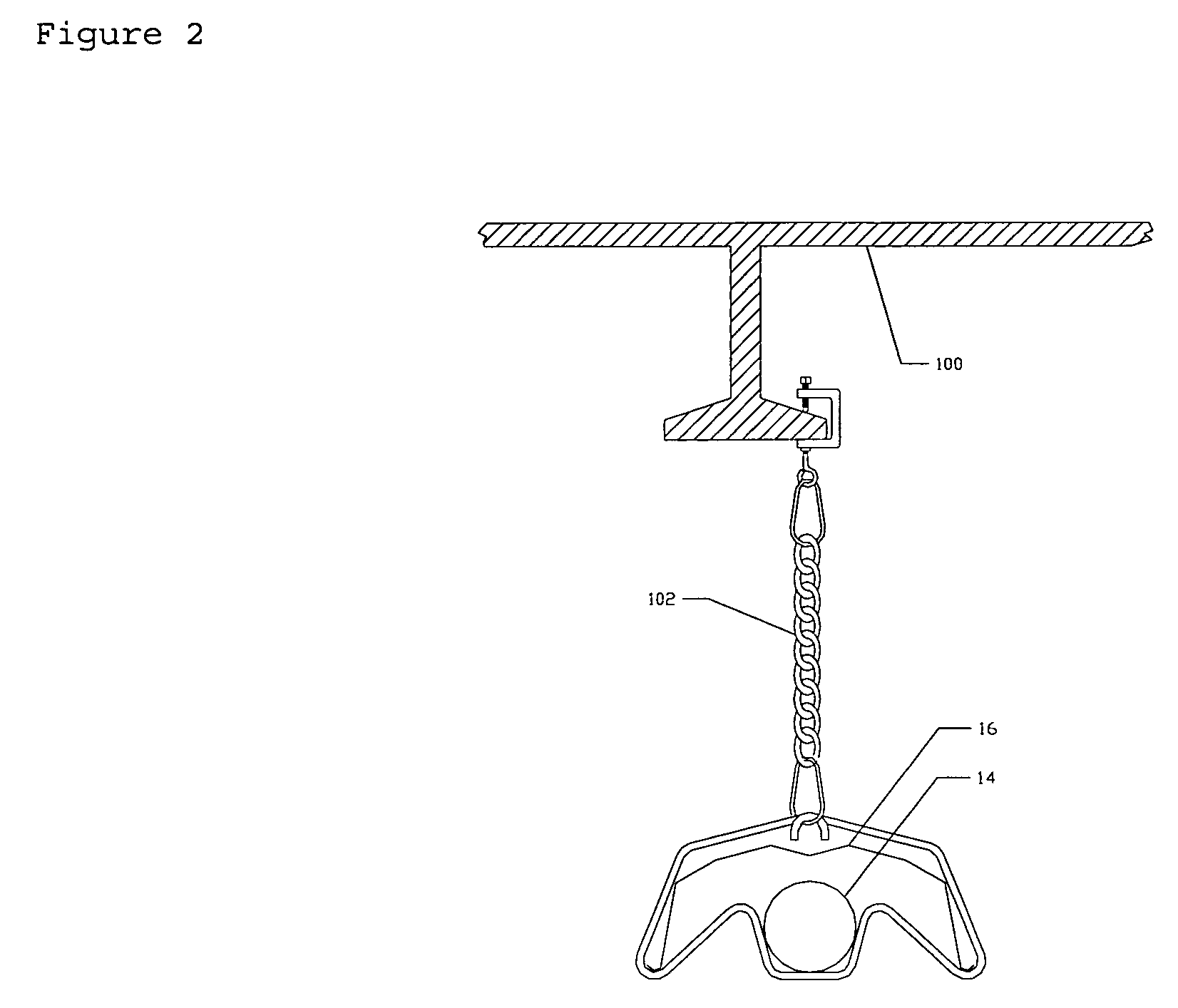

[0013] Generically, the present invention is directed to a single radiant heater or multi-burner radiant heating system. In particular, the present invention is directed to a single radiant heater or multi-burner radiant heating system that modulates the burner input by varying fuel and combustion air supply to the burner's mixing apparatus. The apparatus continuously varies the input of radiant gas heaters that respond to heat demand. The variable input radiant heater apparatus have a burner housing with a combustion air and fuel inlet and a burner assembly for mixing the fuel and air, and conveying the mixture into a heat exchanger for combustion. Combustion takes place inside the heat exchanger and the resulting hot products of combustion are moved through the heat exchanger to the exhaust end due to air pressure from a combustion air blower providing either positive air pressure from the burner end of the heater or negative pressure from the exhaust end of the heater. At the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com