Method for preparing connector-free positive electrode-supported solid oxide fuel cell stack by 3D printing

A technology of solid oxides and fuel cell stacks, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve problems such as industrial applications that have not yet started, and achieve the goals of avoiding batch instability, improving mass transfer rate, and saving preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

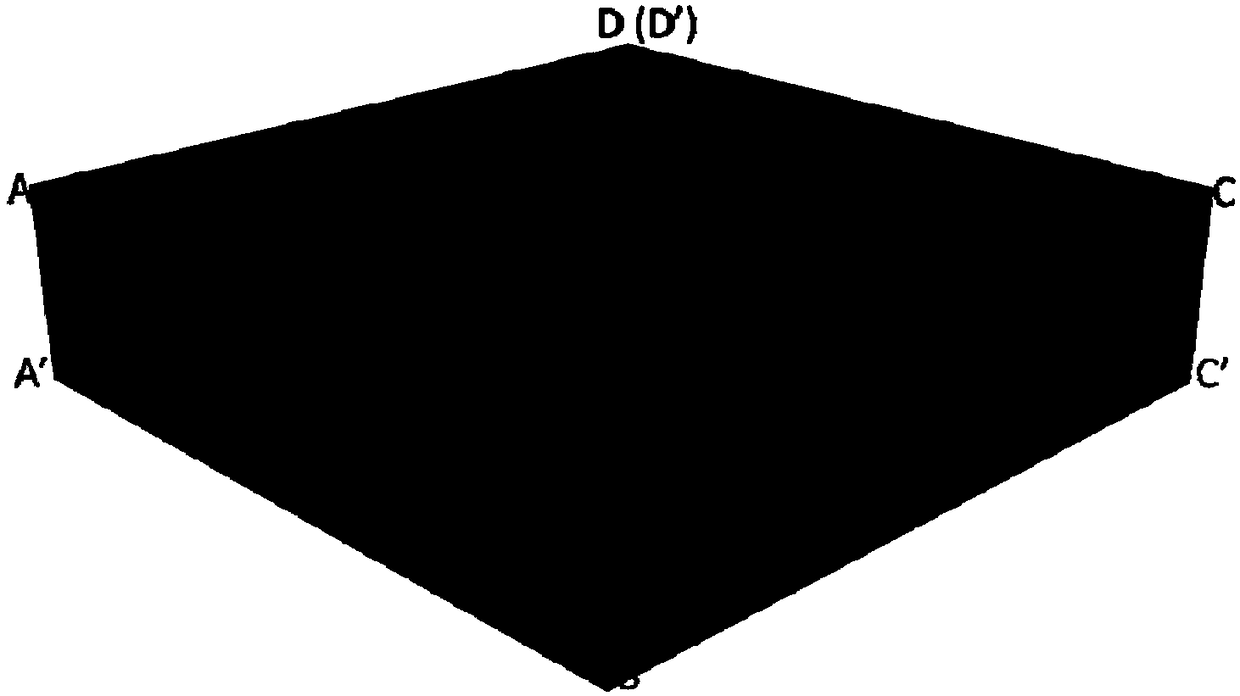

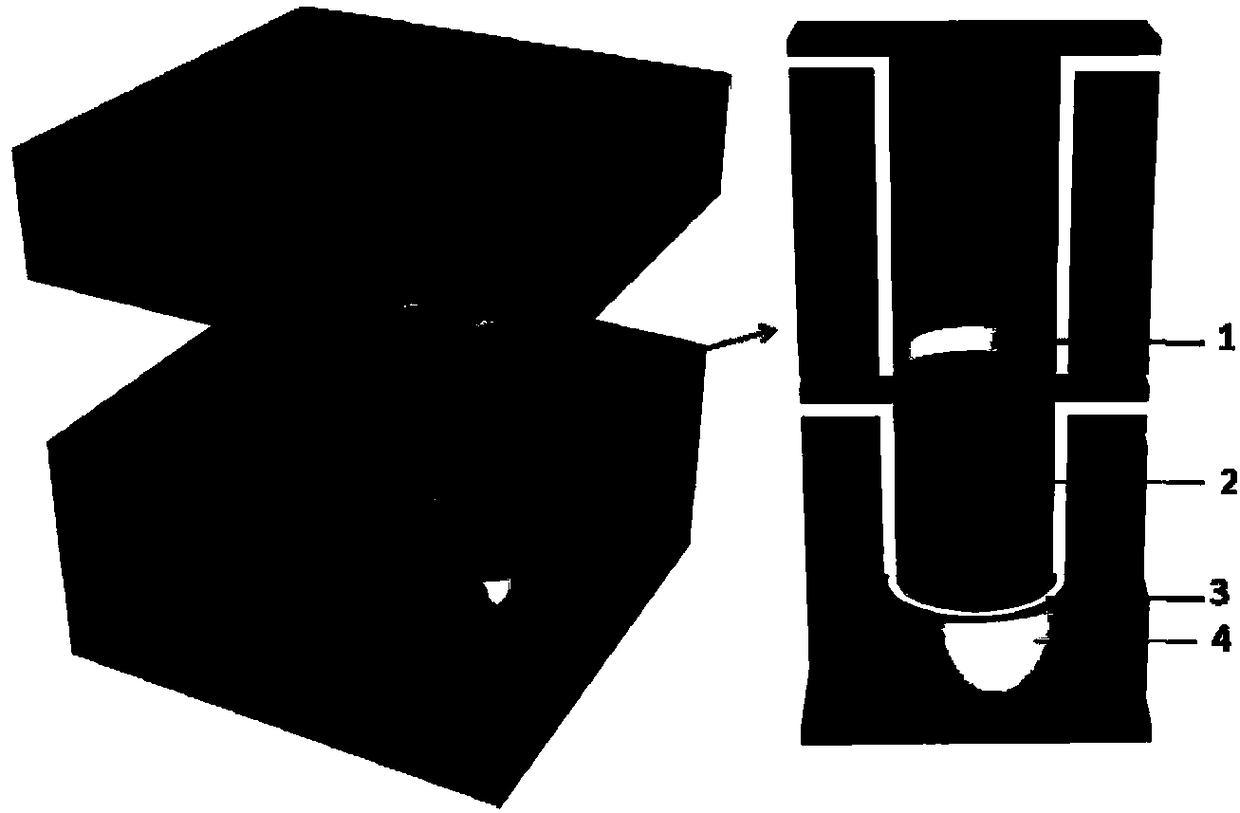

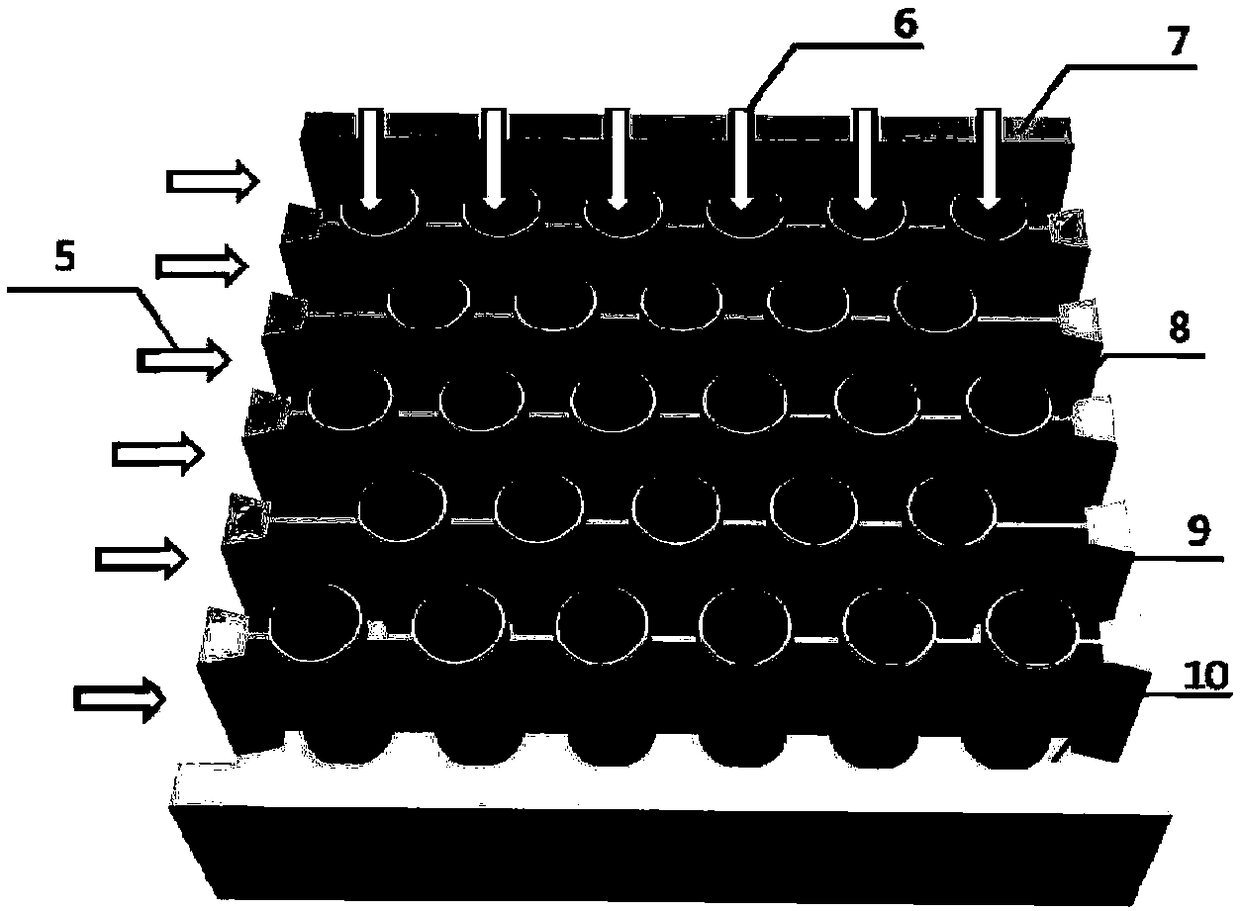

Embodiment 1

[0057] Take 100g Ni-GDC (Gd 0.1 Ce 0.9 o 2-δ ) anode ceramic powder (particle size is 800nm), according to the proportion of 70wt.% powder, 27.3wt.% photosensitive resin and 2.7wt.% ethanol, stirring and mixing for 12 hours, ball milling for 4 hours to form a uniform slurry. Use Catia software to build a three-dimensional channel honeycomb anode support matrix model. The model has a length and width of 2cm and a height of 1cm. There are 28 ceramic microtubes in the vertical direction to provide fluid channels in the tubes, and 6 channels in the horizontal direction to provide fluid channels between the tubes. , whose structure is shown in figure 1 , imported into the CreationWorkshop software for slice printing. The 3D printer adopts the AOTOCERA ceramic 3D printer of Beijing Shiwei Technology Co., Ltd. Add the slurry into the resin tank, and use a computer to control the three-dimensional printer to print the slurry layer by layer according to the designed three-dimension...

Embodiment 2

[0063] 70g Ni-YSZ (Y 0.08 Zr 0.92 o 2-δ ) Anode ceramic powder (with a particle size of 500nm) and 7g of starch are uniformly mixed by a mixer, and the ingredients are mixed according to the ratio of 70wt.% powder, 27.3wt.% photosensitive resin, 1.4wt.% ethanol and 1.3wt.% PEG, and stirred After 12 hours, ball mill for 4 hours to form a uniform slurry. UG software is used to establish a three-dimensional channel honeycomb anode support matrix model. The length and width of the model are 2cm, and the height is 1cm. There are 28 ceramic microtubes in the vertical direction to provide fluid channels in the tube, and 6 channels in the horizontal direction to provide fluid channels between the tubes. , whose structure is shown in figure 1, imported into the CreationWorkshop software for slice printing. The 3D printer adopts the AOTOCERA ceramic 3D printer of Beijing Shiwei Technology Co., Ltd. Add the slurry into the resin tank, and use a computer to control the three-dimensio...

Embodiment 3

[0068] 70g Ni-SDC (Sm 0.2 Ce 0.8 o 2-δ ) Anode ceramic powder (with a particle size of 500nm) and 7g of starch were uniformly mixed with a mixer, and the ingredients were mixed according to the ratio of 70wt.% powder and 30wt.% photosensitive resin, stirred and mixed for 20 hours, and then ball milled for 2 hours to form a uniform slurry. Use 3DMax software to build a three-dimensional channel honeycomb anode support matrix model. The model is 2cm in length and width and 1cm in height. There are 28 ceramic microtubes in the vertical direction to provide fluid channels in the tubes, and 6 channels in the horizontal direction to provide fluid channels between tubes. , whose structure is shown in figure 1 , imported into the CreationWorkshop software for slice printing. The 3D printer adopts the AOTOCERA ceramic 3D printer of Beijing Shiwei Technology Co., Ltd. Put the slurry into the resin tank, use the computer to control the three-dimensional printer to print the slurry la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com