Connecting box and processing method thereof

A processing method and connection box technology, applied to building reinforcements, structural elements, building components, etc., can solve problems such as high welding level requirements, product quality impact, poor product stability, etc., to achieve overall strength and rigidity, Reduce the impact of product quality and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

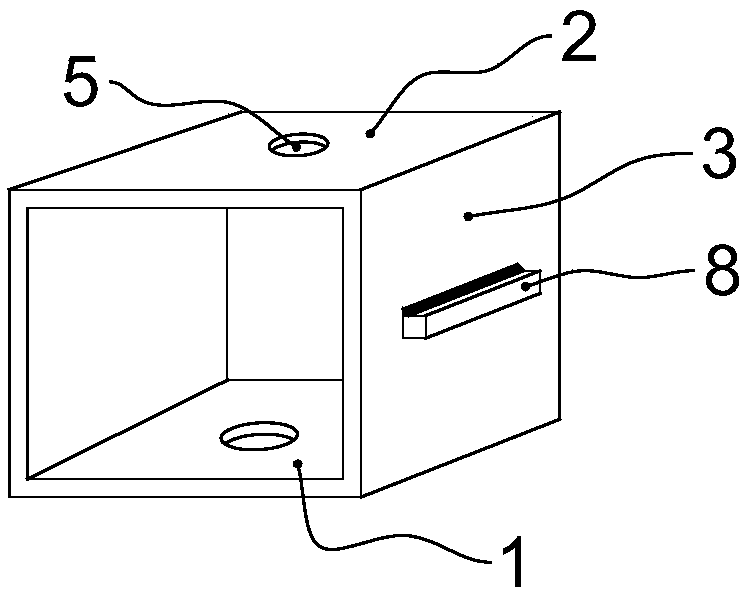

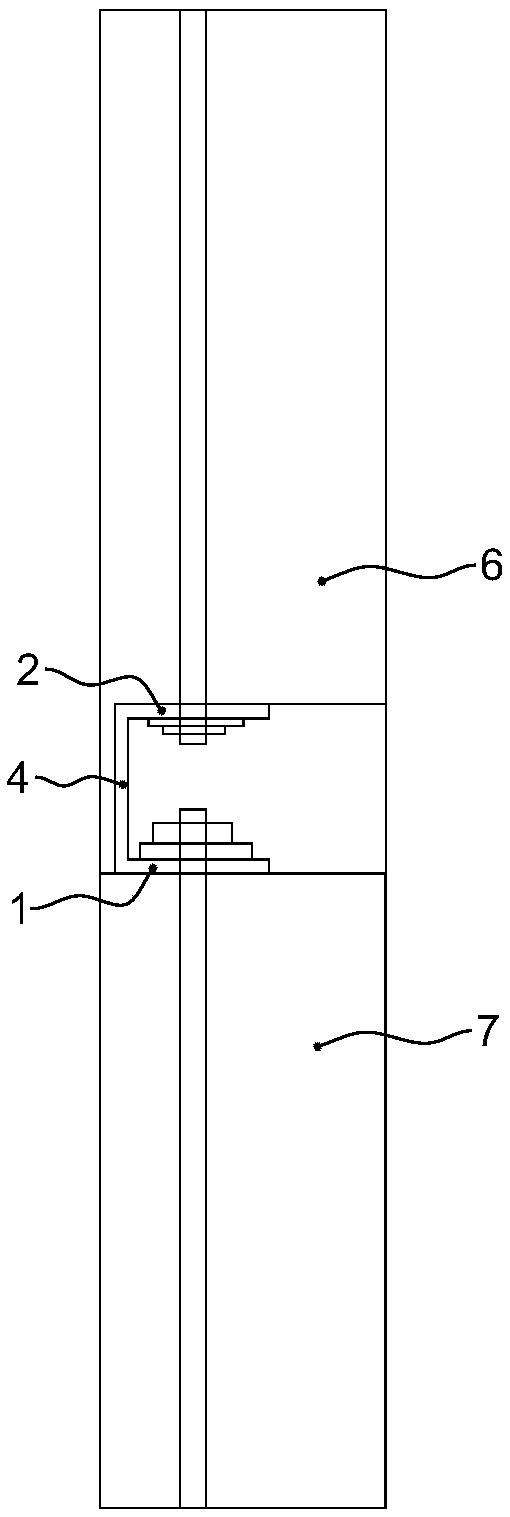

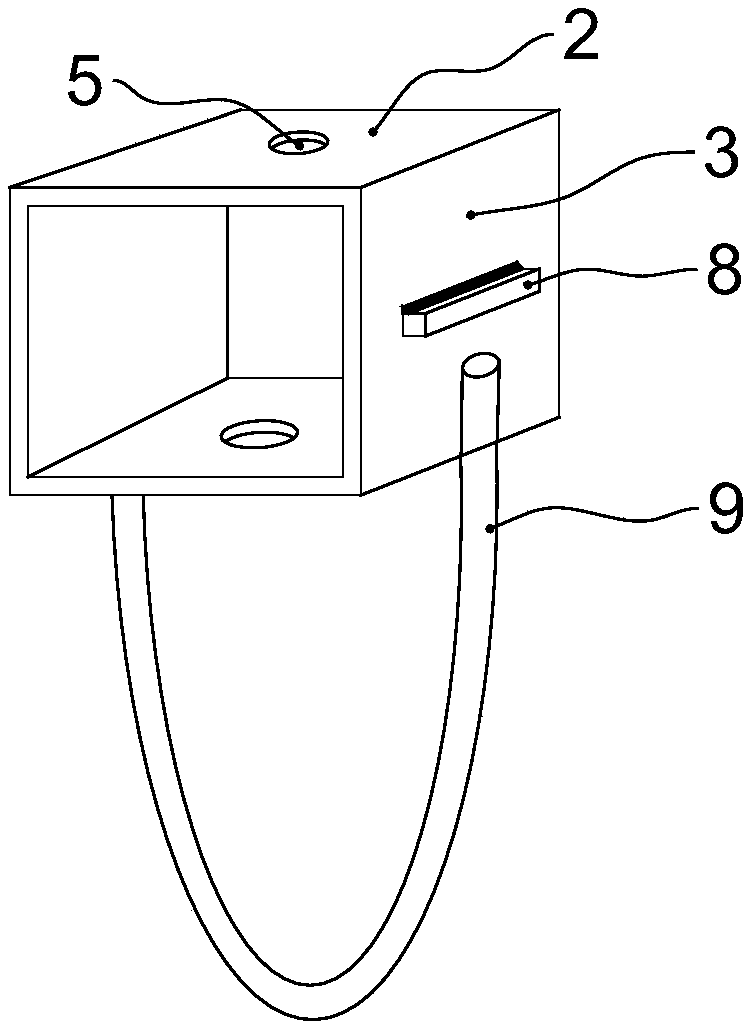

[0026] see Figure 1-3 , a connection box, which includes a bottom plate 1, a top plate 2, two side plates 3 and a back plate 4, the bottom plate 1, top plate 2 and two side plates 3 are formed by cutting square steel pipes, the back The plate 4 is welded and fixed to the bottom plate 1 , the top plate 2 and the side plate 3 at the same time, and the bottom plate 1 and the top plate 2 are provided with through holes 5 for passing steel bars. When using, see figure 2 , the connection box is embedded in the lower end of the upper wallboard 6, the opening of the connection box (opposite to the backboard) faces the inner side of the building, the lower end of the vertical steel bar of the upper wallboard 6 passes through the through hole 5 of the top plate, and uses Fasteners (nuts, spacers, etc.) and / or welding fix this vertical reinforcement in the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com