Method for charging boiling bed catalyst on line

A catalyst and ebullating bed technology, applied in the field of ebullating bed catalyst online filling, can solve the problems of no catalyst wetting and vulcanization treatment, and achieve the effects of simplified operation, convenient treatment and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

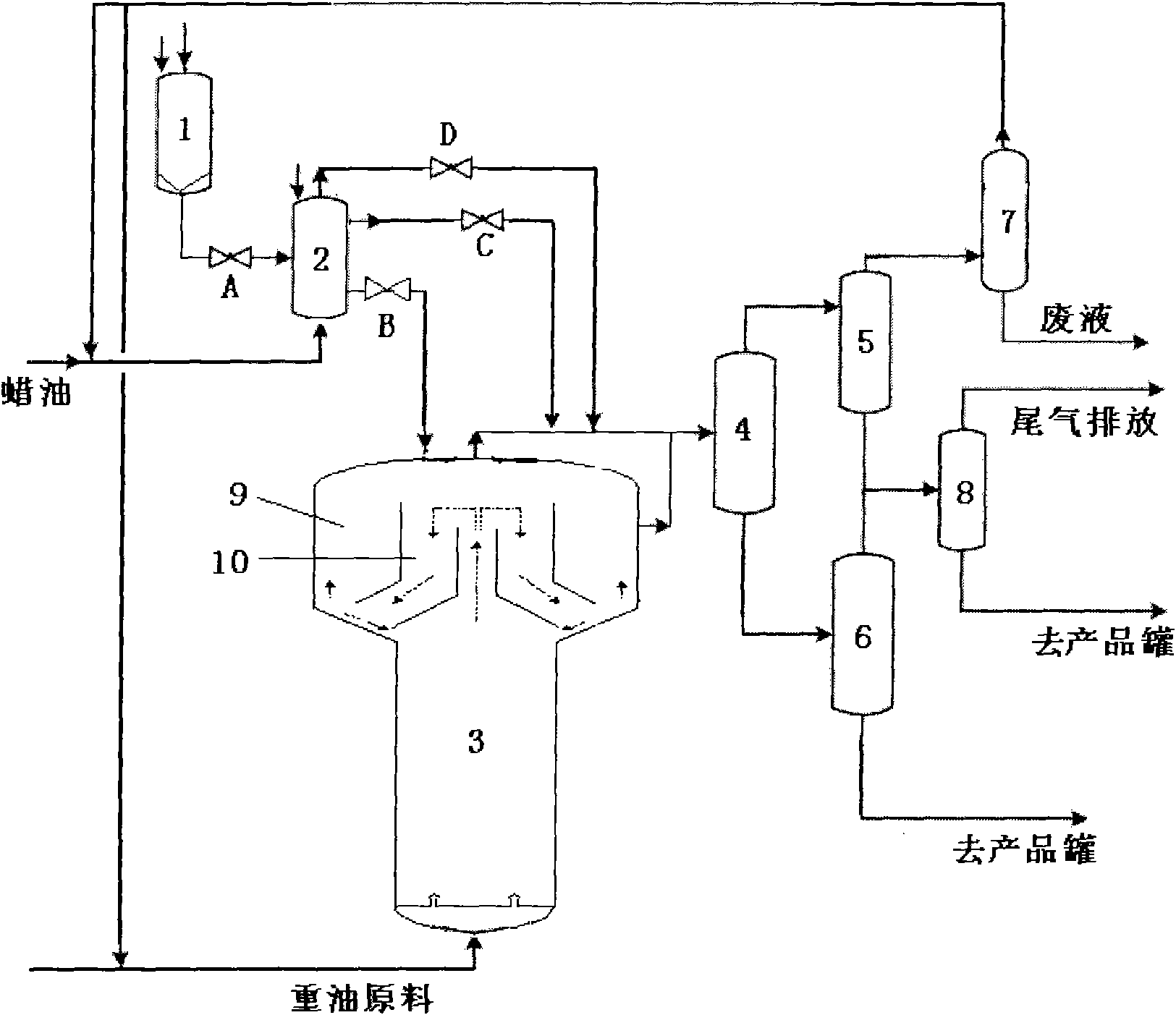

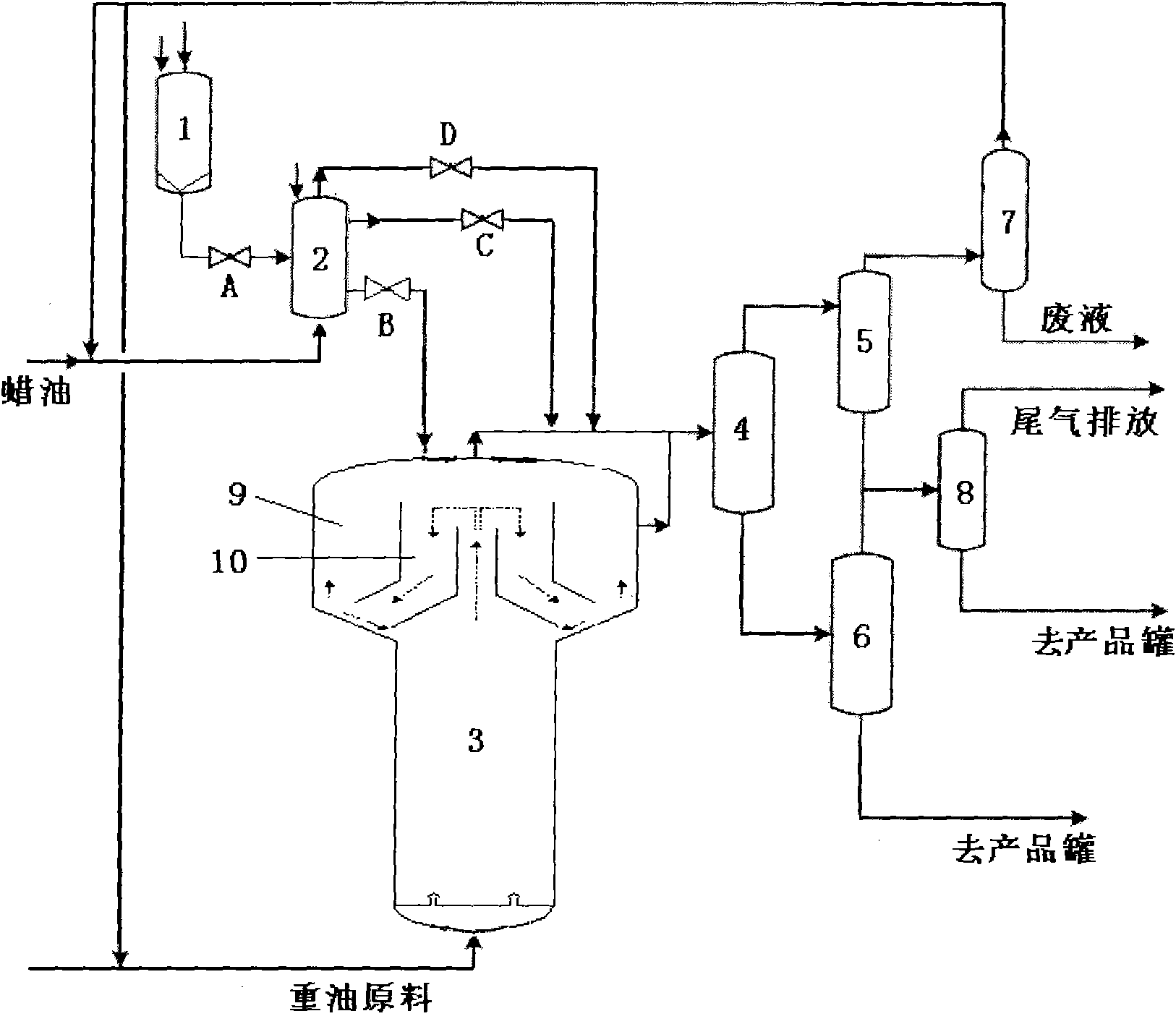

[0039] Catalyst online filling method reference in embodiment 1 figure 1 . Among them, vulcanization conditions, wax oil space velocity 1.2h -1 , the volume ratio of hydrogen to oil is 600:1, vulcanize at a constant temperature of 270°C for 6h, then raise the temperature of the catalyst filling tank to 320°C and vulcanize at a constant temperature for 6h, after the vulcanization is completed, raise the temperature of the catalyst filling tank to 385°C, and the pressure to 15.5MPa, Open the pipeline for online filling. Catalyst filling frequency is 1kg catalyst / t heavy oil raw material.

[0040] The catalyst is a presulfided catalyst, and the composition is that the active metal is Mo-Ni, where Mo is MoO 3 The content of Ni is 13.62%, and the NiO content is 2.83%. The particle size of the catalyst is 0.2mm, and the bulk density is 0.60g cm -3 , the specific surface area is 260m 2 / g, the average pore diameter is 15nm.

[0041] The operating conditions of the ebullated be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com