Automatic glue spreading machine

A gluing machine and automatic technology, applied in the field of gluing machines, can solve the problems of low work efficiency, high labor intensity, and low consistency of gluing quality, so as to improve production efficiency, high gluing precision and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

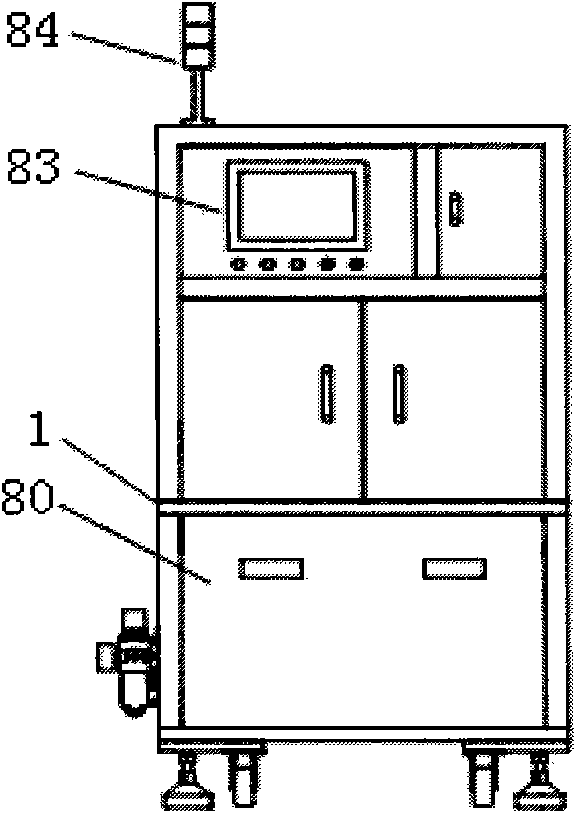

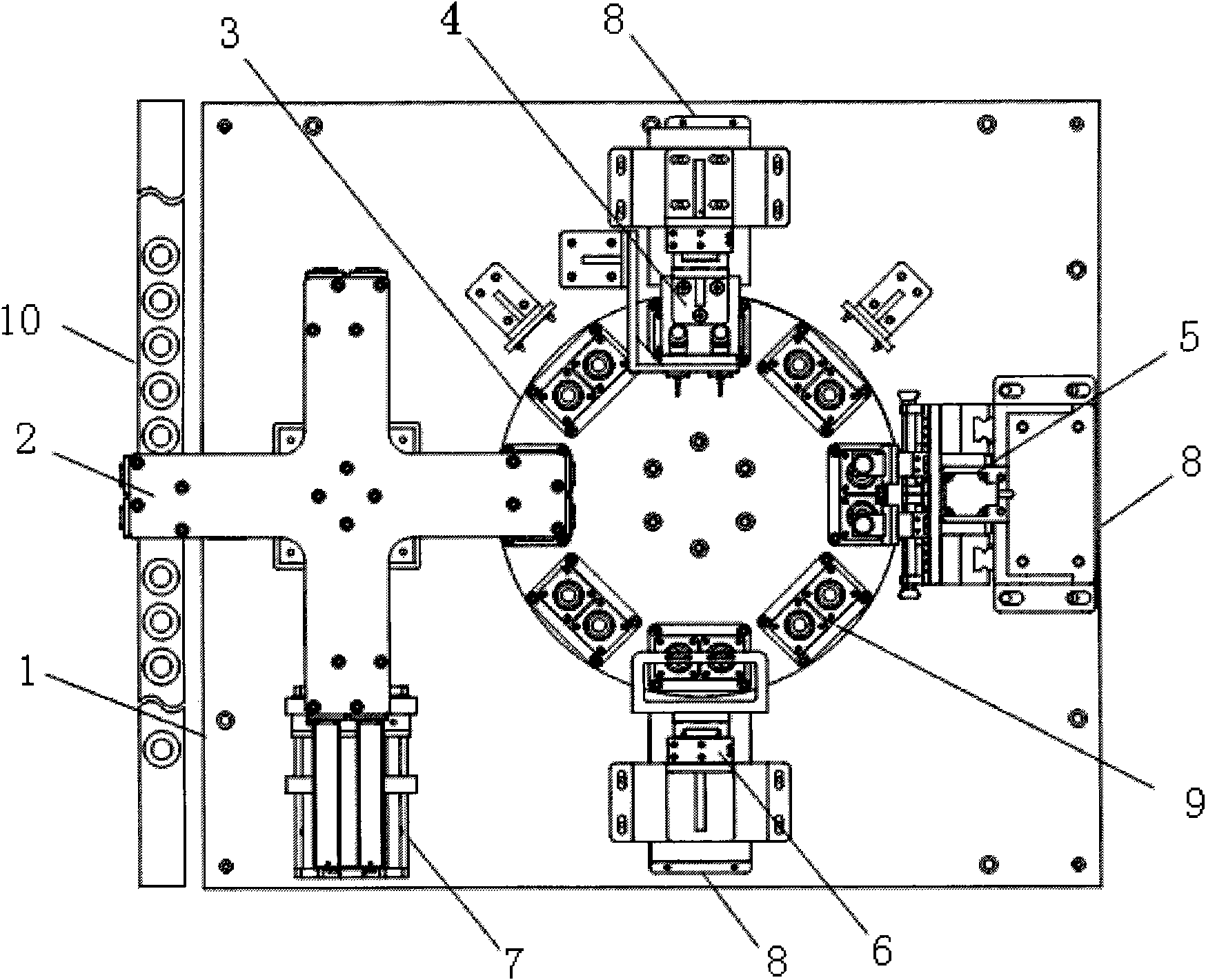

[0019] see Figure 1 to Figure 3 As shown, the automatic gluing machine of the present invention is mainly used for the gluing operation of cylindrical batteries after rolling grooves, and it includes a frame 1 and a manipulator 2 located on the frame 1, a feeding turntable 3, a positioning device 4, a gluing Device 5, gluing detection device 6 and defective material recycling mechanism 7.

[0020] Please also refer to Figure 4 As shown, the manipulator 2 is a four-arm manipulator with four stations. For clarity, this manual will image 3 The leftmost station shown in is called the first station, and the other three stations are called the second, third and fourth stations in clockwise order. The first station of the manipulator 2 corresponds to the conveyor belt 10, mainly grabbing the unglued workpiece from the conveyor belt 10 and putting the glued workpiece on the conveyor belt 10, so that the workpiece flows into the next process; the third station Corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com