Aluminum-plated propylene and butylene co-polypropylene tape casting membrane material and preparation method thereof

A technology of aluminum-propylene-butylene copolymerized polypropylene and acrylonitrile-butylene copolymerized polypropylene, which is applied in the field of aluminized polypropylene casting film materials, can solve the problems of increasing the content of low-molecular random substances, high n-hexane extracts, and limiting the application range, etc., to achieve Good melt fluidity, improved impact resistance, enhanced processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

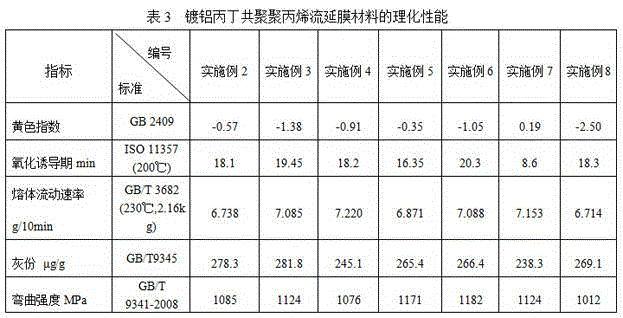

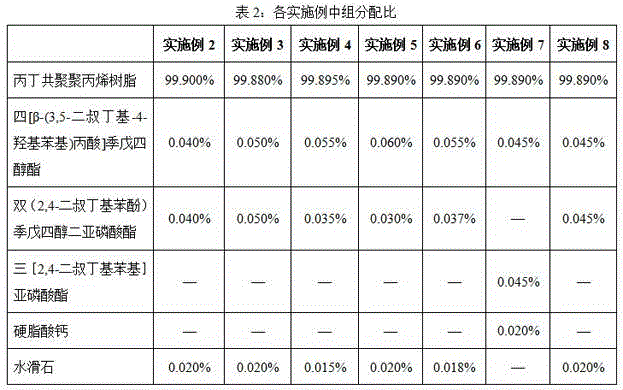

Examples

Embodiment 1

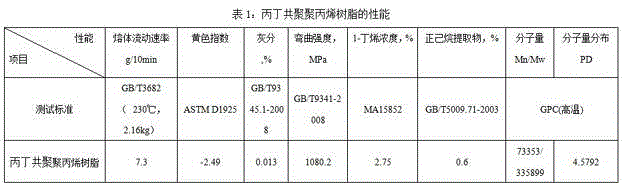

[0027] Embodiment 1: the preparation of propylene-butylene copolymer polypropylene resin:

[0028] 1. The raw materials for the production of base resin are the following substances:

[0029] 1) Polymer grade propylene

[0030] project purity% Water content 10 -6 CO content10 -6 CO 2 Content 10 -6 index ≥99.35 ≤5 ≤0.2 ≤4

[0031] 2) Catalyst DQ-Ⅲ, cocatalyst TEAL, electron donor DONOR, antistatic agent Atmer163

[0032] 3) Hydrogen

[0033] project purity% Water content 10 -6 CO content10 -6 Total Sulfur Content10 -6 index ≥95 ≤5 ≤5 ≤1

[0035] project typical value Butene-1 ≥99% by weight Butene-2 ≤0.1% weight percentage Isobutylene ≤0.5% weight percentage Butane + Isobutane ≤0.4% weight percentage 1,3-Butadiene ≤120ppm mole Acetylene ≤5ppm mole total carbonyl compounds ≤10ppm mole Methanol ≤10ppm mole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com