Method for producing high-purity silver nitrate

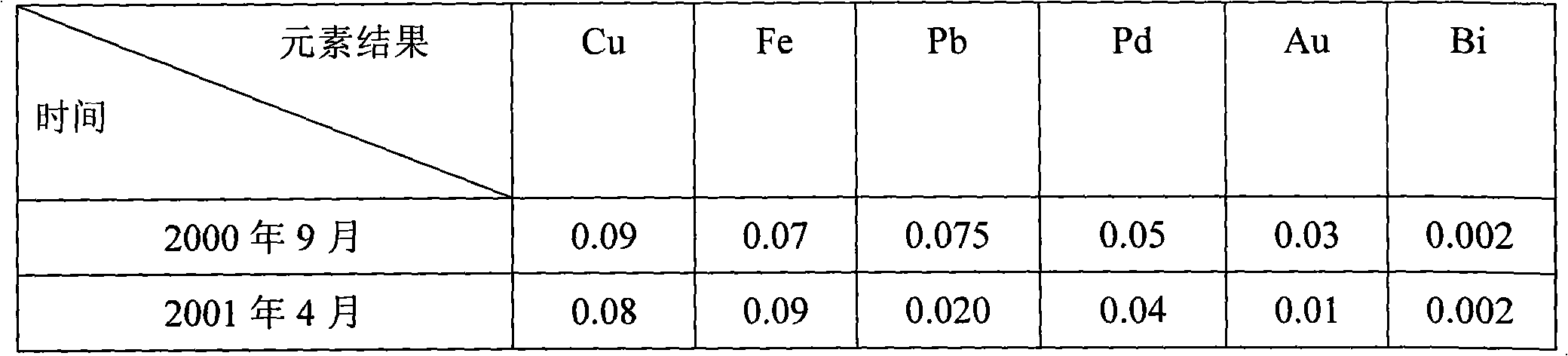

A production method, silver nitrate technology, applied in chemical instruments and methods, silver compounds, silver compounds, etc., can solve the problems of low product purity and achieve high quality, improved product quality, and low metal content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A kind of method of producing high-purity silver nitrate of the present invention, it may further comprise the steps:

[0020] (1) Reaction: Take silver and wash it with pure water to remove surface dirt, then place it in a reaction kettle, add distilled pure nitric acid in batches, keep excess silver during the reaction, heat to 70°C, under negative pressure Remove excess nitrogen compounds and adjust the pH value of the reaction solution to PH3.5;

[0021] (2) Hydrolysis: add the above-mentioned reaction solution into the hydrolysis kettle, dilute it with pure water until the density is 1.65g / cm3, add the impurity removal agent magnesium oxide, stir slowly, then cool and stand for 13 hours, filter to remove impurities, and obtain the filtrate;

[0022] (3) Evaporation and crystallization: send the filtrate after removing impurities into the evaporation and crystallization kettle, evaporate under reduced pressure, stir slowly, and cool and crystallize when the specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com