Equipment for producing small-sized copper flat wire

A technology for production equipment and flat copper wire, applied in the field of production equipment for small flat copper wire, can solve the problems of high price, high production cost, complex structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

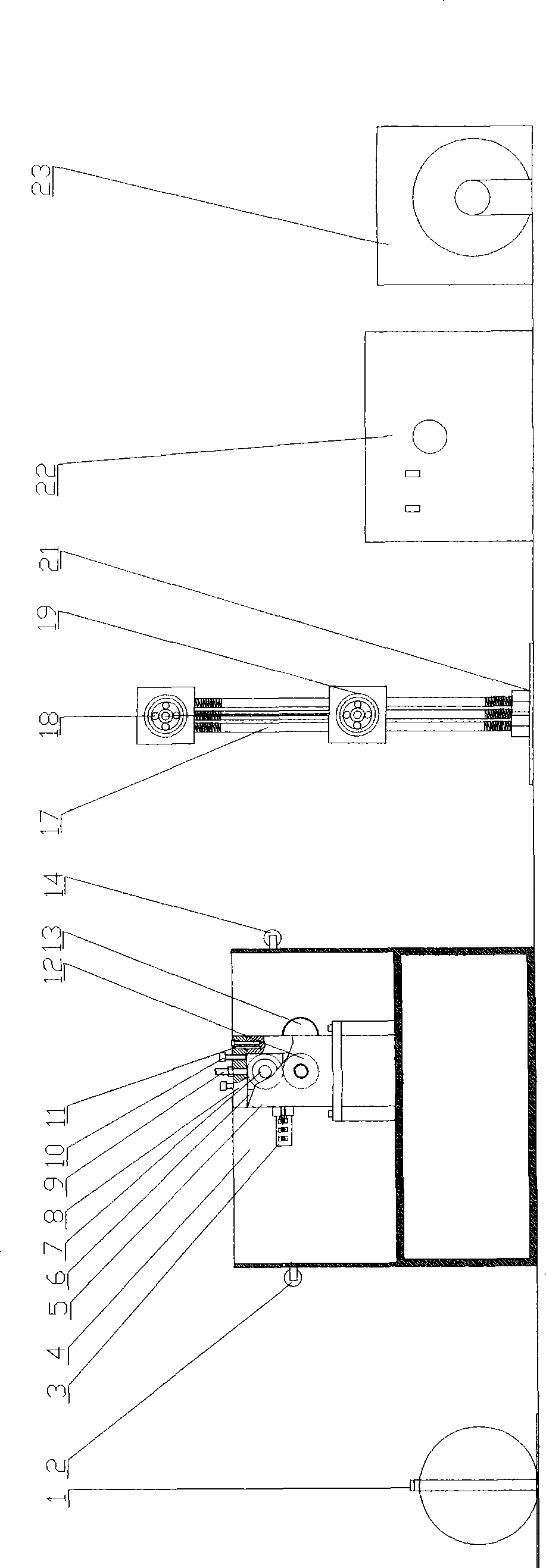

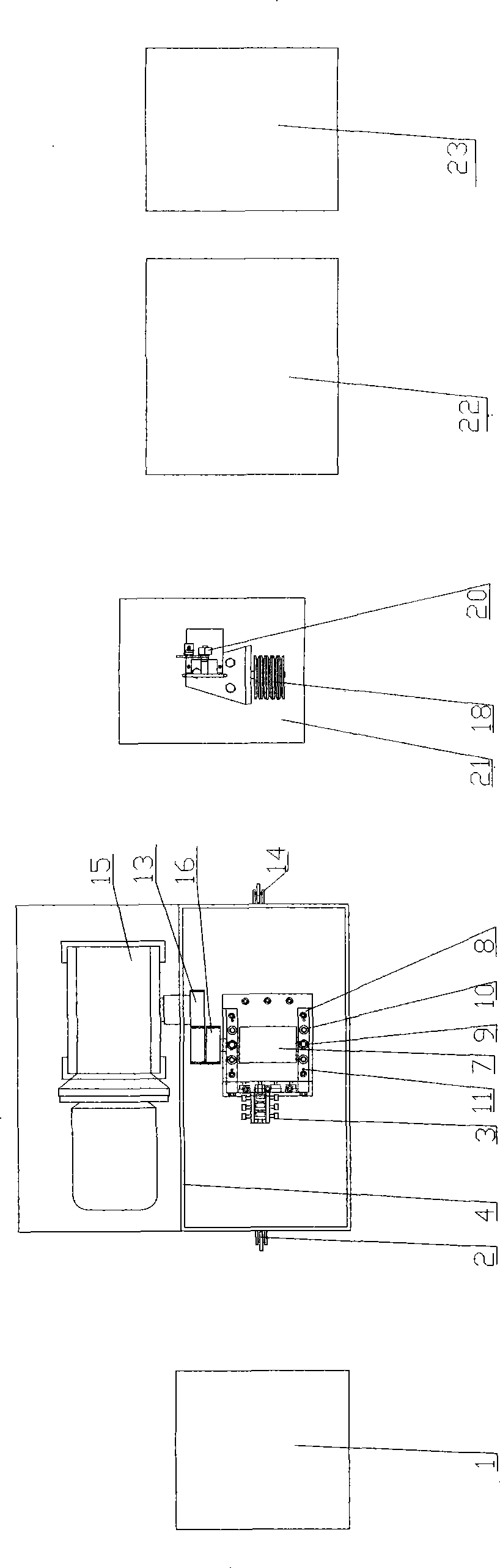

[0012] The drawing-rolling combination small copper flat wire production equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] see Attachment.

[0014] The production equipment of small copper flat wire is composed of pay-off device 1, rolling mill 4, drawing and rolling adapter 21, wire drawing machine 22, wire take-up machine 24, wire pay-off device 1, rolling mill 4, drawing and rolling adapter 21, wire drawing machine 22, wire take-up The machines 23 are arranged in an orderly manner according to the running direction, and are arranged as a wire payoff 1, a rolling mill 4, a drawing and rolling adapter 21, a wire drawing machine 22, and a wire take-up machine 23.

[0015] The rolling mill 4 is composed of a housing, a fixed bracket 6, a detachable bracket 8, a mold tensioner 3, an upper roll 7 and a lower roll 12, the fixed bracket 6 is fixed in the housing, and the 12 bearing seats of the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com