Intensive ultra-large-scale radial tire production system of high-performance car

A radial tire, ultra-large-scale technology, applied in tires, other household appliances, household appliances, etc., can solve the problem that there is no method for defining the super-long structure in essence, the design method has not been established, and the effect of temperature difference and shrinkage creep has not been obtained. Good research and other issues, to achieve the effect of flexible layout and technical transformation, shorten transportation distance and time, and reduce production land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

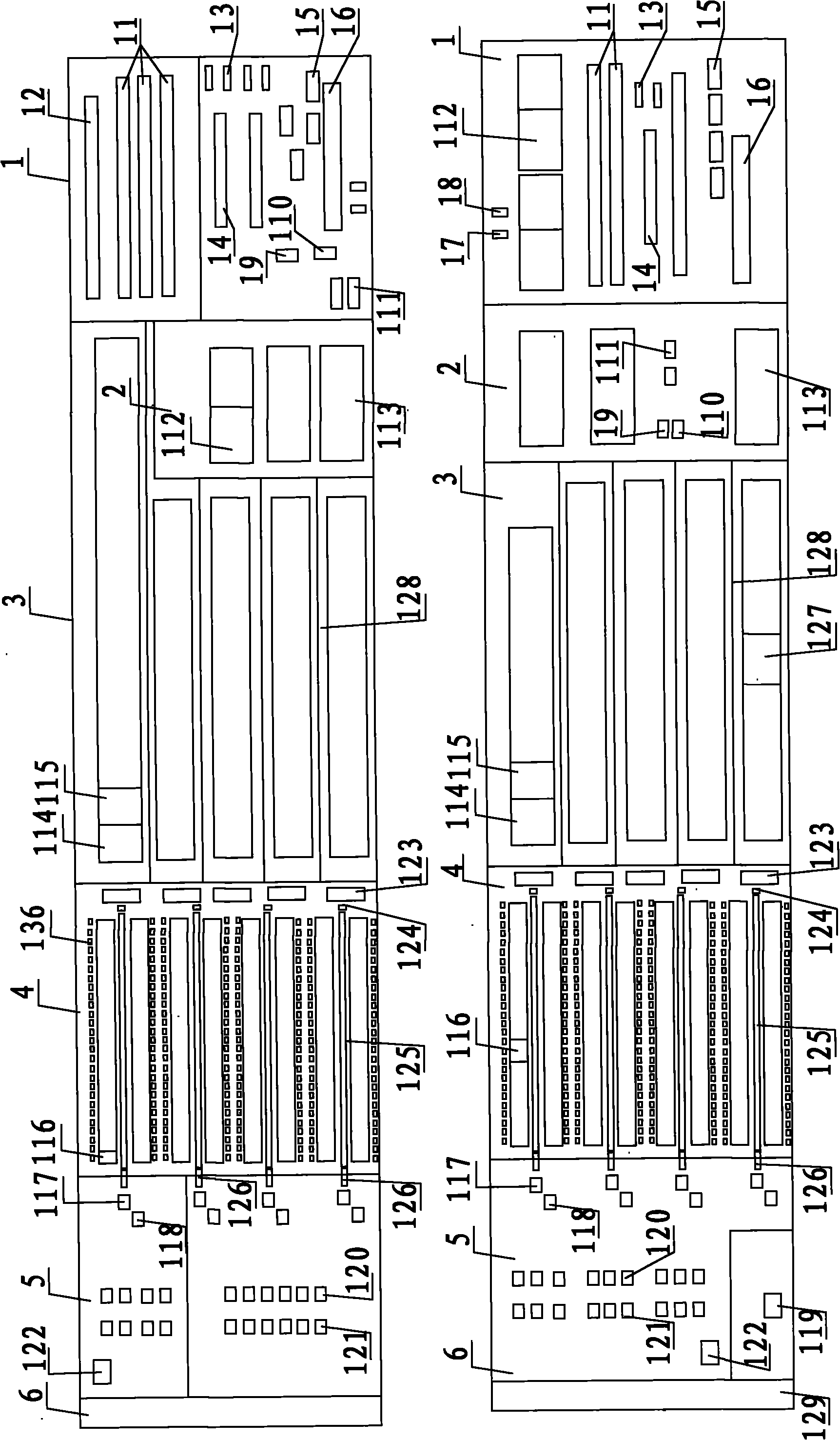

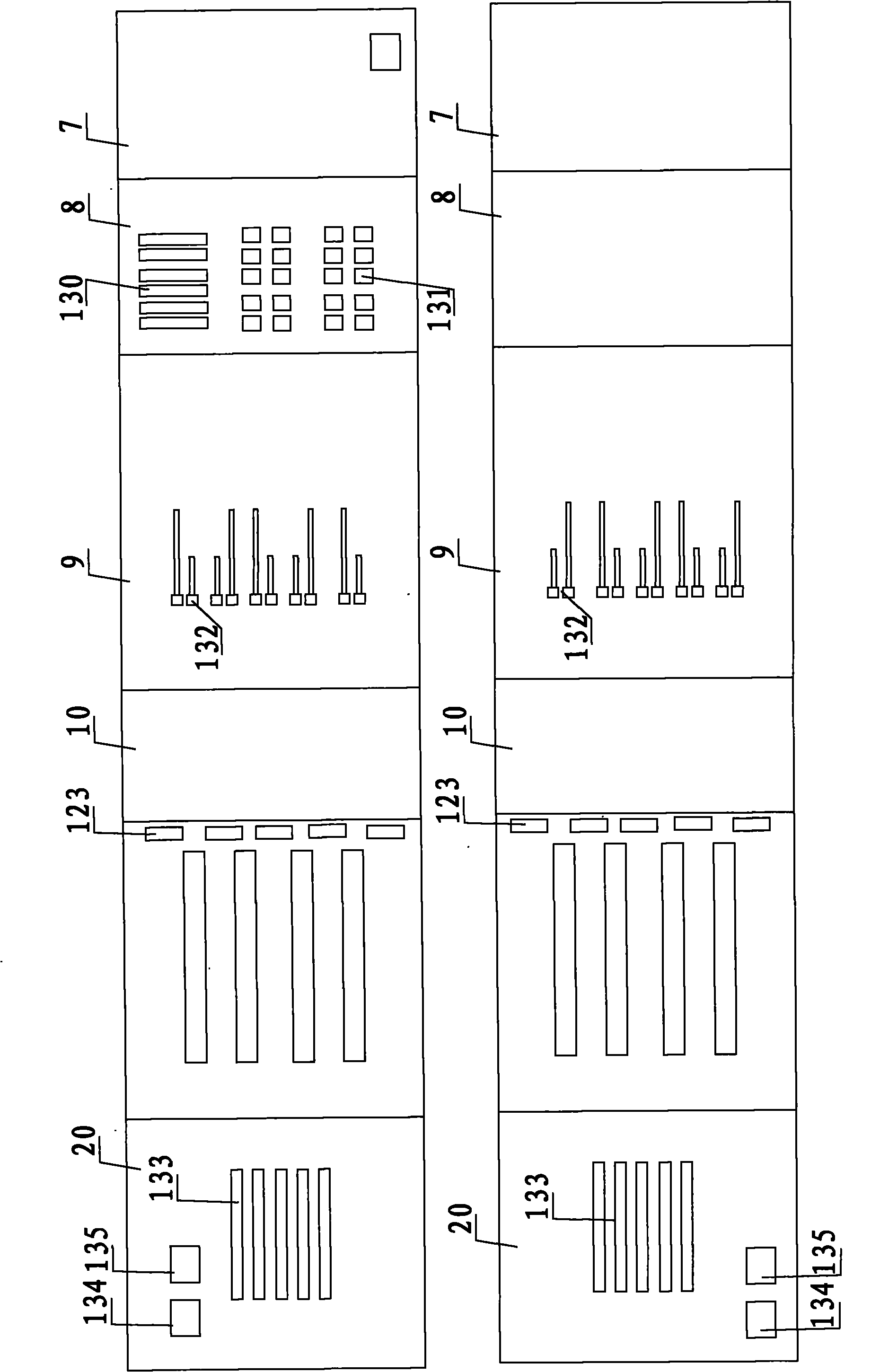

[0027] Such as Figure 1 ~ Figure 3 The intensive ultra-large-scale high-performance car radial tire production system shown, the total area of the production system ≥ 250,000 m 2 , total height ≥ 23.5m, length ≥ 450m, width ≥ 190m. The production system consists of Area A and Area B, and Area A and Area B are respectively composed of three-story building workshops. The first layer of area A is respectively set up in sequence for semi-product extrusion and calendering area 1, cutting area 2, molding area 3, vulcanization area 4, finished product inspection area 5, and storage and delivery area 6. The second layer includes the mixed rubber storage area 7, Semi-finished product production area 8, tire blank spraying area 9, tire blank storage area 10 and finished tire storage area 20, semi-finished product production area 8 is equipped with 20 apex laminating machines 131 and 6 bead ring extrusion and rolling production lines 130 , The third layer includes tire edging area 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com