Visual detection machine of automobile lock catch rivet point

A technology of automobile locks and detection machines, which is applied in the field of parts detection, can solve problems such as difficult to achieve detection goals, low precision, instability, etc., and achieve the effects of saving detection costs, improving work efficiency, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in combination with specific embodiments.

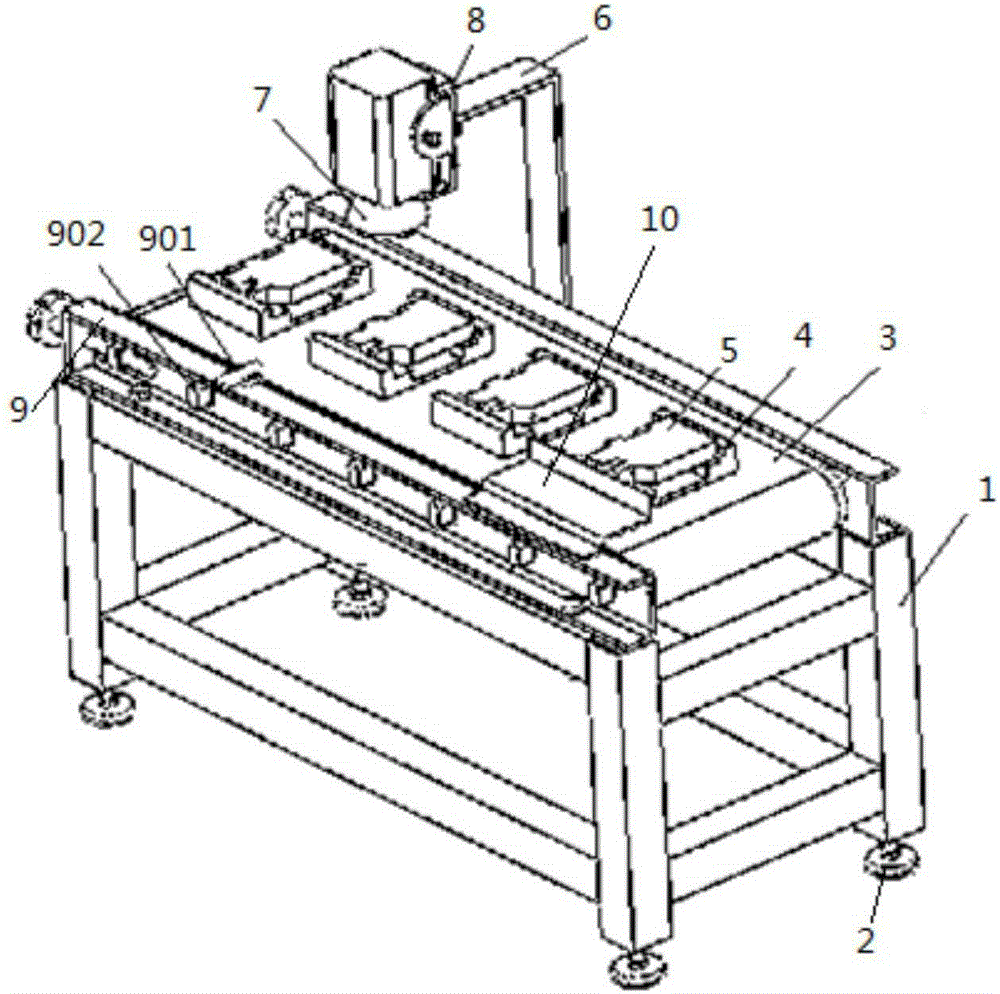

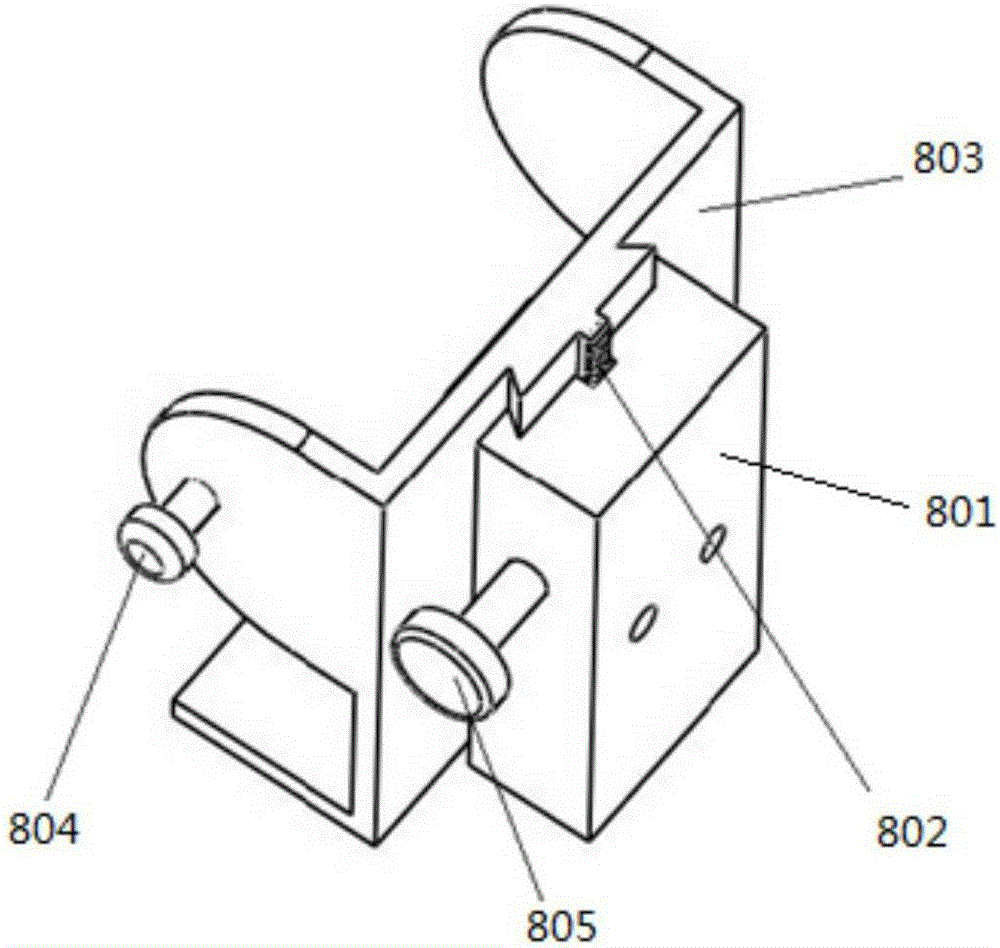

[0012] A visual inspection machine for the riveting point of the automobile lock according to the present invention is as follows: figure 1 with figure 2 As shown, it includes a frame 1, the four legs below the frame 1 are provided with supporting pads 2, and the top of the frame 1 is provided with a transmission device 3 as a workbench. The transmission device 3 is composed of a pulley, a roller and a conveyor belt. Fixed, the conveyor belt is installed on the roller, the conveyor 3 is provided with a carrier 4, the lock 5 is placed in the carrier 4, a camera fixing bracket 6 is installed on one side of the frame 1, and a bracket fine-tuning device 8 is installed on the camera fixing bracket 6 , the camera 7 is fixed on the bracket fine-tuning device 8, the camera 7 is located above the transmission device 3, the lens of the camera 7 is aimed at the lock 5, the camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com