Method for automatically assembling gear reducer

A technology of gear reducer and gear shaft, which is applied in the direction of assembly machine, workpiece clamping device, metal processing equipment, etc., can solve the problems of increased manufacturing cost, large labor consumption, slow manual assembly speed, etc., and achieves strong assembly stability, High degree of automation and good product uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

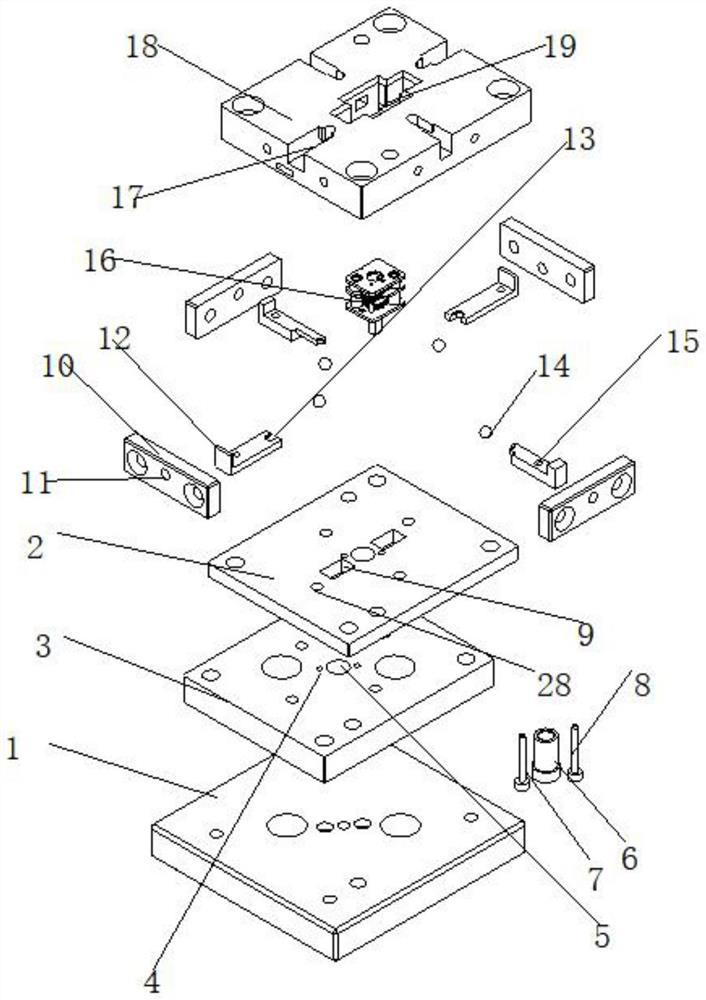

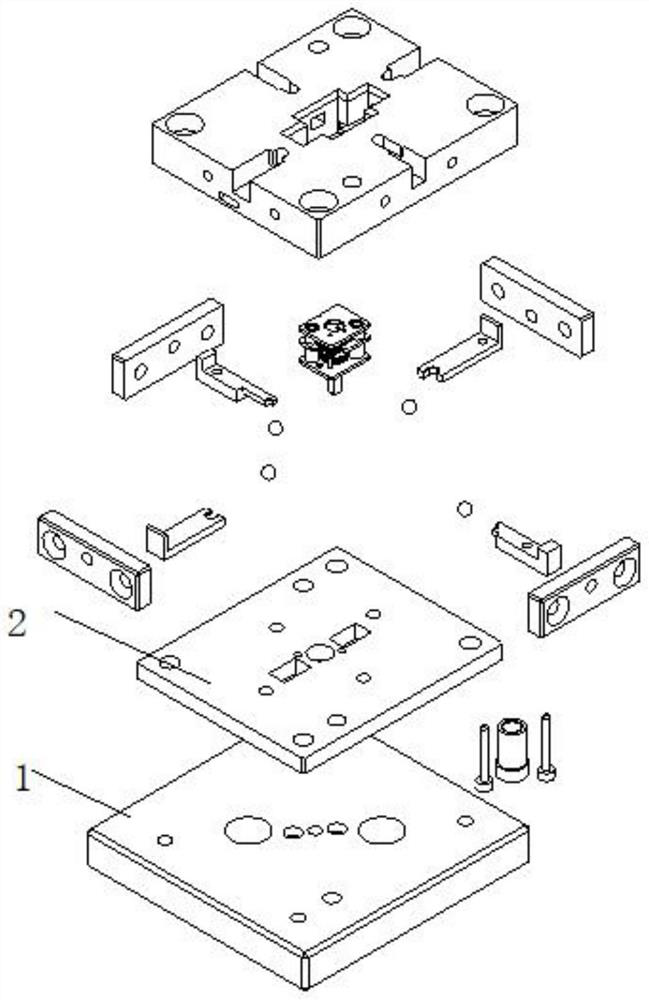

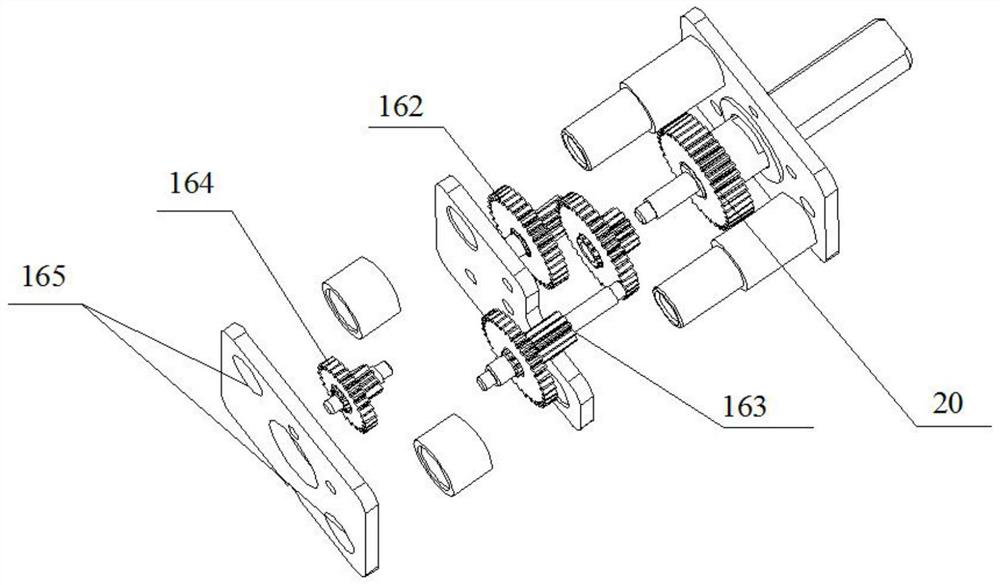

[0051] Embodiment 1: In combination with all the accompanying drawings; an automatic assembly tool for a gear reducer, characterized in that the tool includes a base plate 1 on which a fixing cylinder 6 and two fixing columns are fixed, and the two fixing columns are fixed columns one 7 and two fixed columns 8; the fixed cylinder 6 and the two fixed columns pass through the corresponding holes on the assembly reference plate 2, and also include a top plate 18, which is fixed on the assembly reference plate 2 and the bottom plate 1 by bolts; on the top plate 18 The middle part contains the operation hole 19, and the fixed cylinder 6 and the two fixed columns are located in the operation hole 19 facing upwards. The output shaft 20 of the workpiece 16 can be inserted downward into the fixed cylinder 6. The workpiece contains a workpiece positioning hole 165, and the fixed columns can be inserted into the fixed cylinder 6. The entire workpiece can be positioned in the workpiece pos...

Embodiment 2

[0053] Embodiment 2: As a further improved solution or a side-by-side solution or an optional independent solution, the workpiece 16 is a gear reducer; the through hole in the middle of the fixed cylinder 6 is used to avoid the output shaft 20, which is suitable for different lengths and outer dimensions. The output shaft 20 of diameter, flat position. The substantive technical effect and the realization process of the technical solution here are as follows: the gear reducer of this patent is the preferred assembly object, in fact, it can also be assembled with a multi-axis system, and similar solutions are also within the scope of protection of this patent Inside.

Embodiment 3

[0054] Embodiment 3: As a further improved solution or a side-by-side solution or an optional independent solution, more than one ball 14 is included on the assembly reference plate 2, and the lower part of the ball 14 is located in the ball groove 28. 14 slide block, the end of the slide block includes a push plate arc section 13; the push plate arc section 13 can relatively locate the gear shaft; the slide block can move in the moving groove 17. The substantive technical effect and the realization process of the technical solution here are as follows: refer to the method of the second solution, which is mainly for positioning and straightening the shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com