Simple prefabricated building curtain wall

A prefabricated and simple technology, used in construction, building components, building structures, etc., can solve the problems of difficult disassembly, cumbersome disassembly, inconvenient installation, etc., and achieves strong assembly stability, easy operation, and improved stability. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

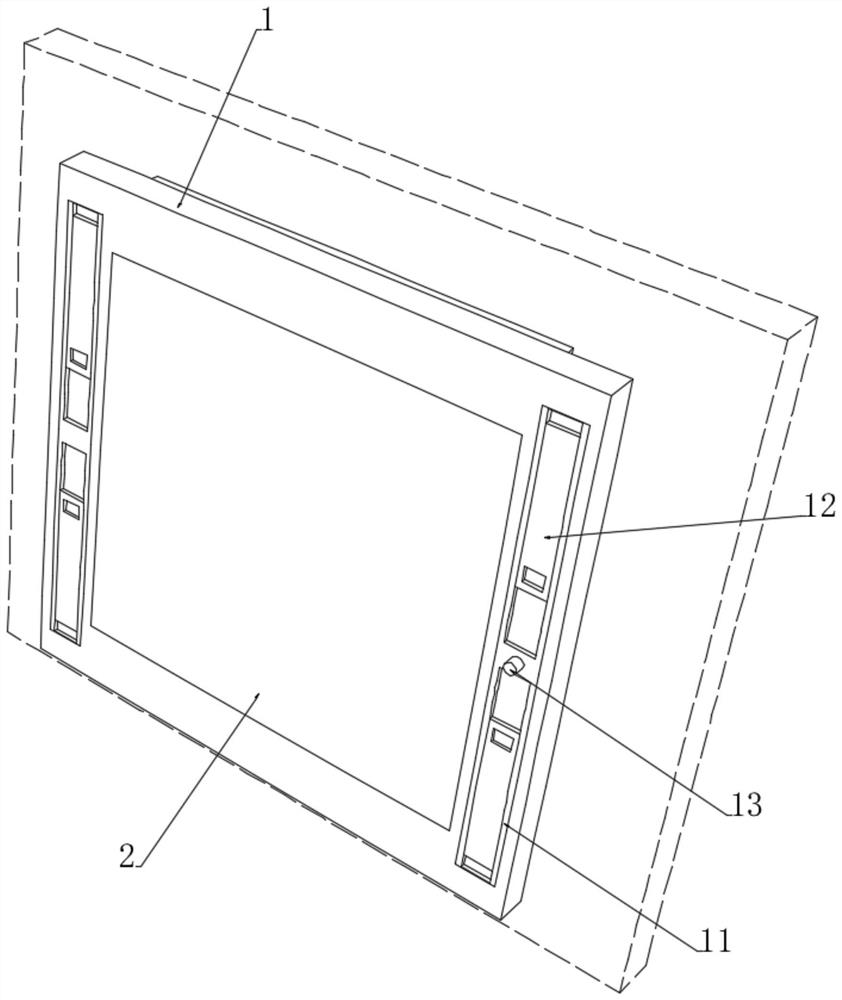

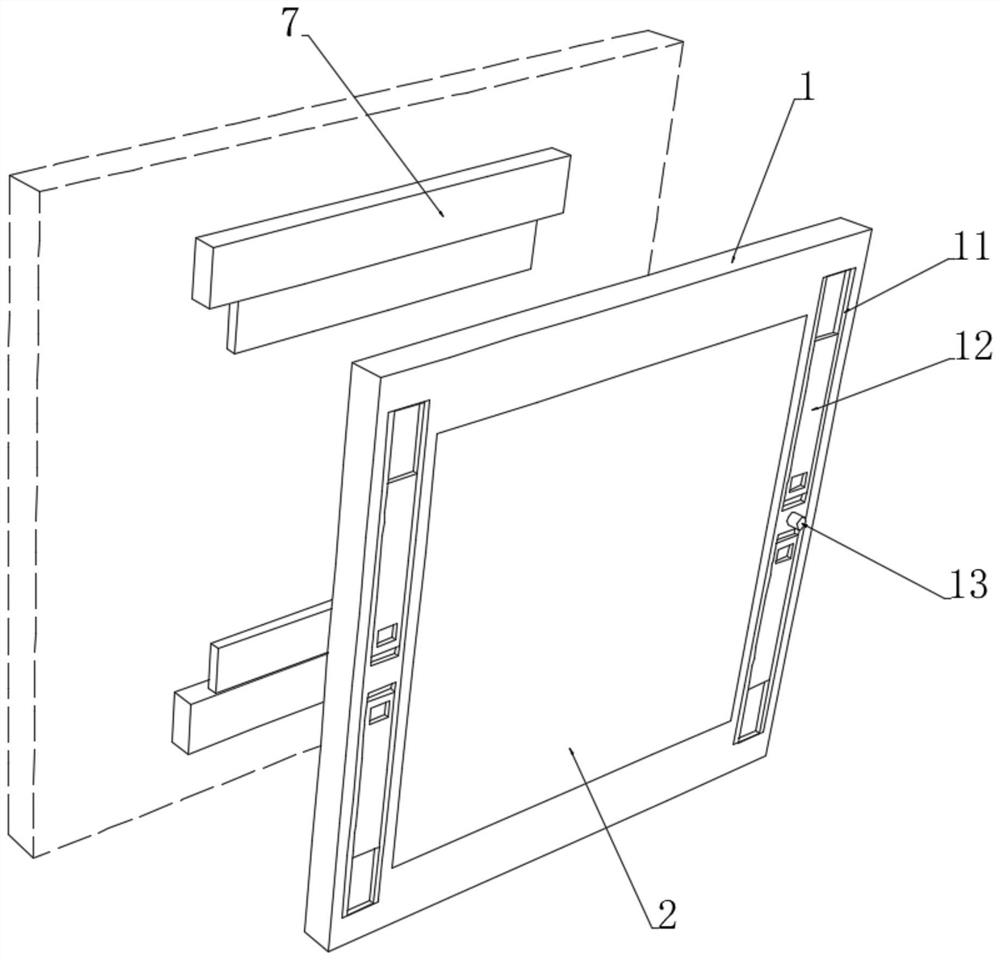

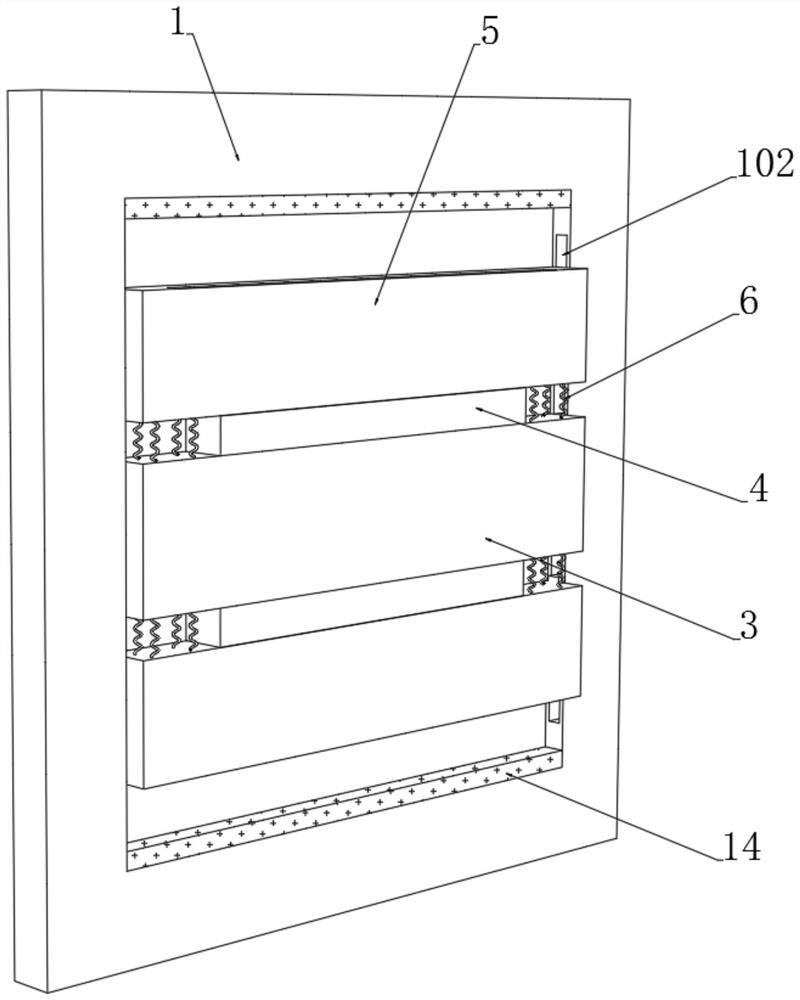

[0041] see Figure 1-6 , a simple prefabricated building curtain wall, including an outer curtain wall embedded and installed on the outer wall, the outer curtain wall is composed of an outer frame 1 and a glass wall 2 embedded in the outer frame 1, the glass wall 2 is embedded in the outer The front end of the frame 1, the glass wall 2 and the rear end of the outer frame 1 form an installation cavity, and the outer end surface of the glass wall 2 is flush with the front end surface of the outer frame 1, and a connecting seat 3 is provided in the middle of the installation cavity. The upper and lower end walls of the connecting seat 3 are connected with the matching assembly seat 5 through the drum filling box 4, and a pair of assembly plates 7 corresponding to the position of the assembly seat 5 are fixedly connected on the outer end wall of the outer wall body. 5. On the side wall exposed outside the installation cavity, there is an assembly cavity 501 embedded with the asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com