Anti-inversion brake component with accelerated wind cooling and capability of reducing wear of brake pad

A technology for accelerated cooling and brake components, which is applied to the components of the brake, the axial brake, the type of the brake, etc., and can solve the problems of poor safety performance of the device, high maintenance costs, and poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

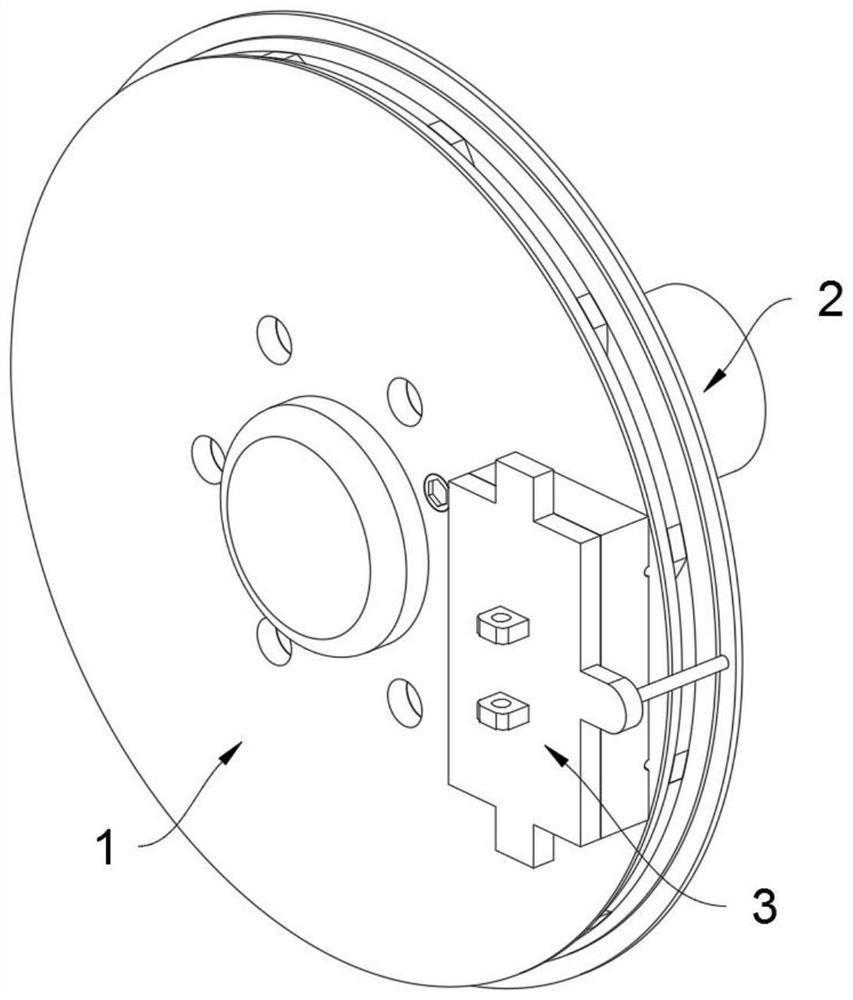

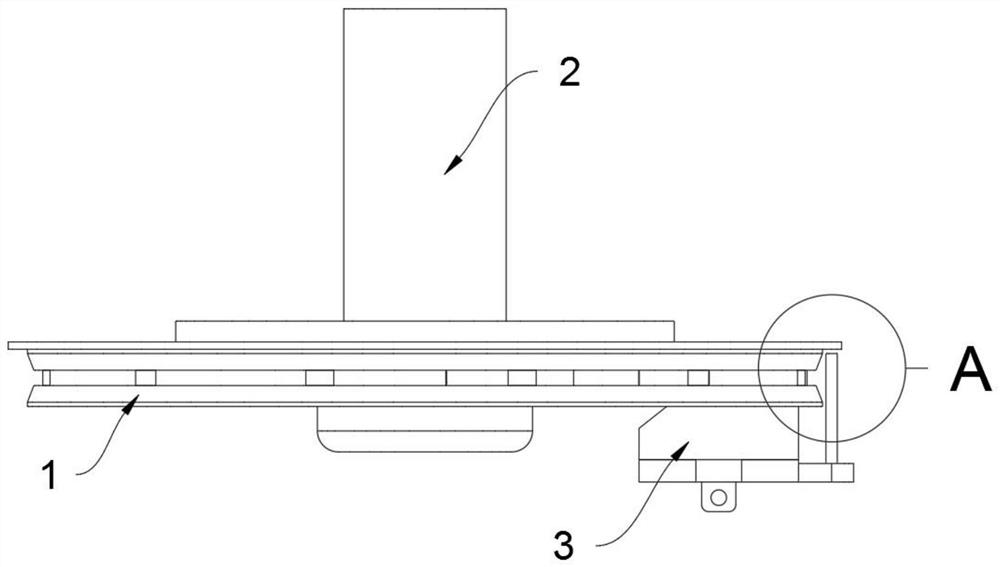

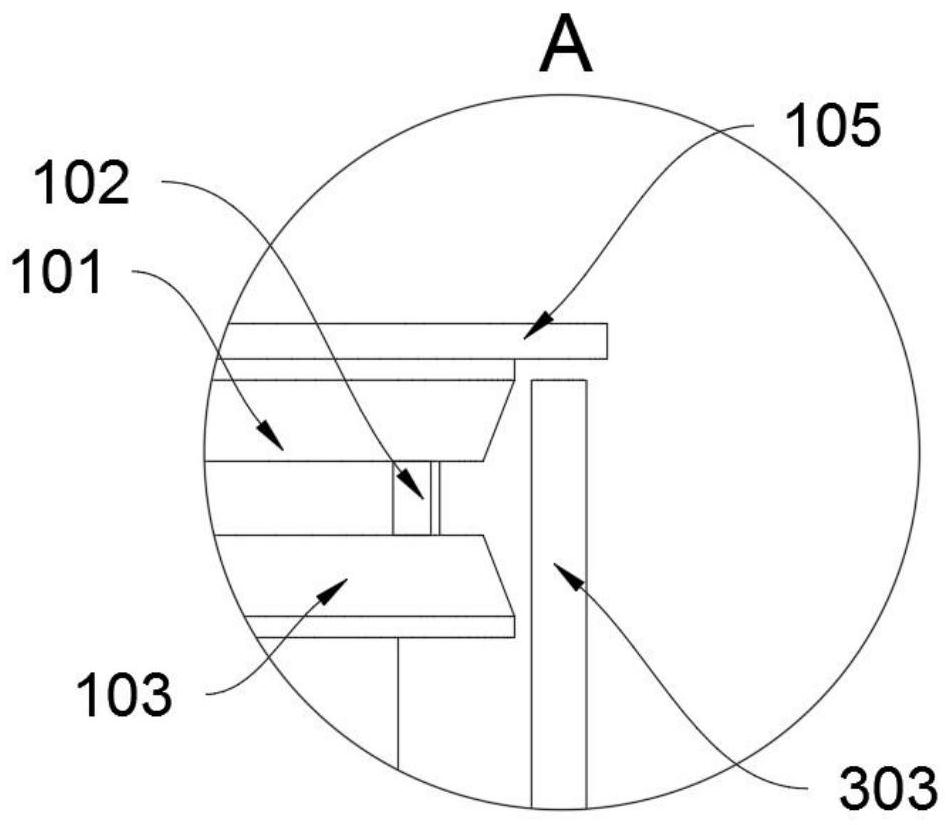

[0035] as attached figure 1 To attach Figure 9 Shown:

[0036] The invention provides an anti-flip brake assembly with wind accelerated cooling and reduced brake pad wear, comprising a brake disc structure 1 and a brake pad structure 3; the brake disc structure 1 is fixedly connected to the hub 2 through bolts; the brake pad structure 3 is connected to the brake Disc structures 1 are in contact with each other; refer to e.g. Figure 8 , the brake pad structure 3 includes a fixed seat 301, a brake pad 302 and an airflow groove 30201, the fixed seat 301 is fixedly connected with a brake pad 302, and two airflow grooves 30201 are symmetrically opened on the brake pad 302; the head end of the brake pad 302 is inclined Angle treatment, and the head end of the brake pad 302 is connected with the airflow groove 30201, and the airflow groove 30201 is a wave-like structure, so that the cooling efficiency of the brake disc main body 103 can be improved through the airflow groove 3020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com