Fireworks group basin split plastic outer cylinder

A split type and outer cylinder technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of affecting the launch and viewing effects of fireworks, the difficulty of manual insertion, and the poor insertion effect, so as to save materials and assemble Strong stability and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

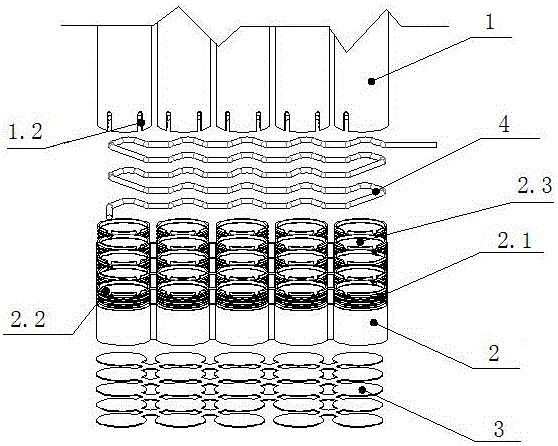

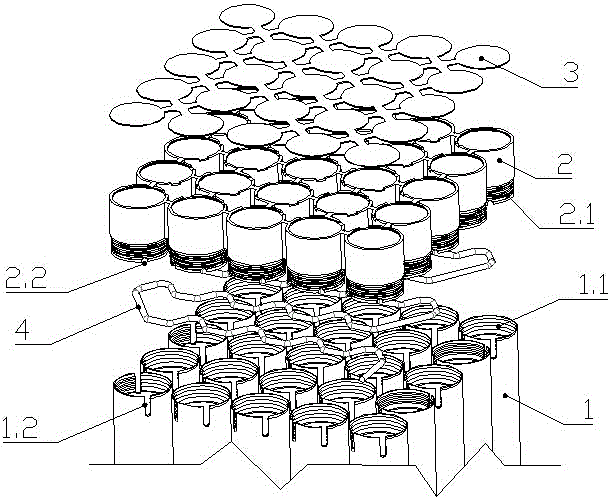

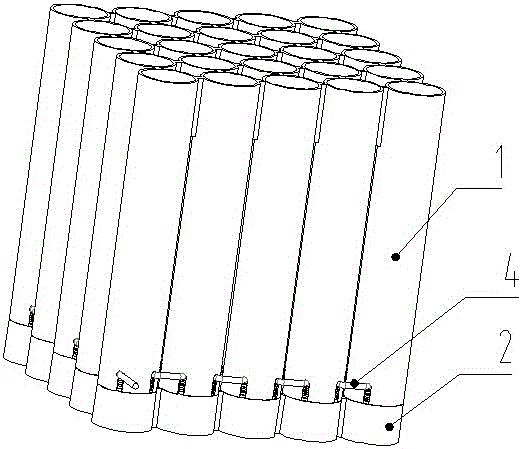

[0012] The content of the invention of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0013] See attached Figure 1-Figure 3 , the split-type plastic outer cylinder of the firework pot, including a plurality of integrally formed outer cylinders 1 and a plurality of integrally formed bases 2, wherein the lower end of the inner wall of each outer cylinder 1 is provided with an inner card slot 1.1, and the upper end of the outer wall of each base 2 is opened. There is an outer card slot 2.1, and each outer cylinder 1 is installed on the corresponding base 2 through the matched inner card slot 1.1 and outer card slot 2.1, and there are two staggered angles of 30-90° at the lower end of each outer tube 1 The inverted U-shaped lead groove 1.2 of each base 2 also has two U-shaped lead grooves 2.2 matched with the inverted U-shaped lead groove 1.2, and the inverted U-shaped lead groove 1.2 and the corresponding U-shaped lead groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com