Automatic hinge assembling machine

A technology for assembly machines and hinges, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low automation and low hinge assembly efficiency, achieve less manual intervention, reduce labor intensity of workers, and strong assembly stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

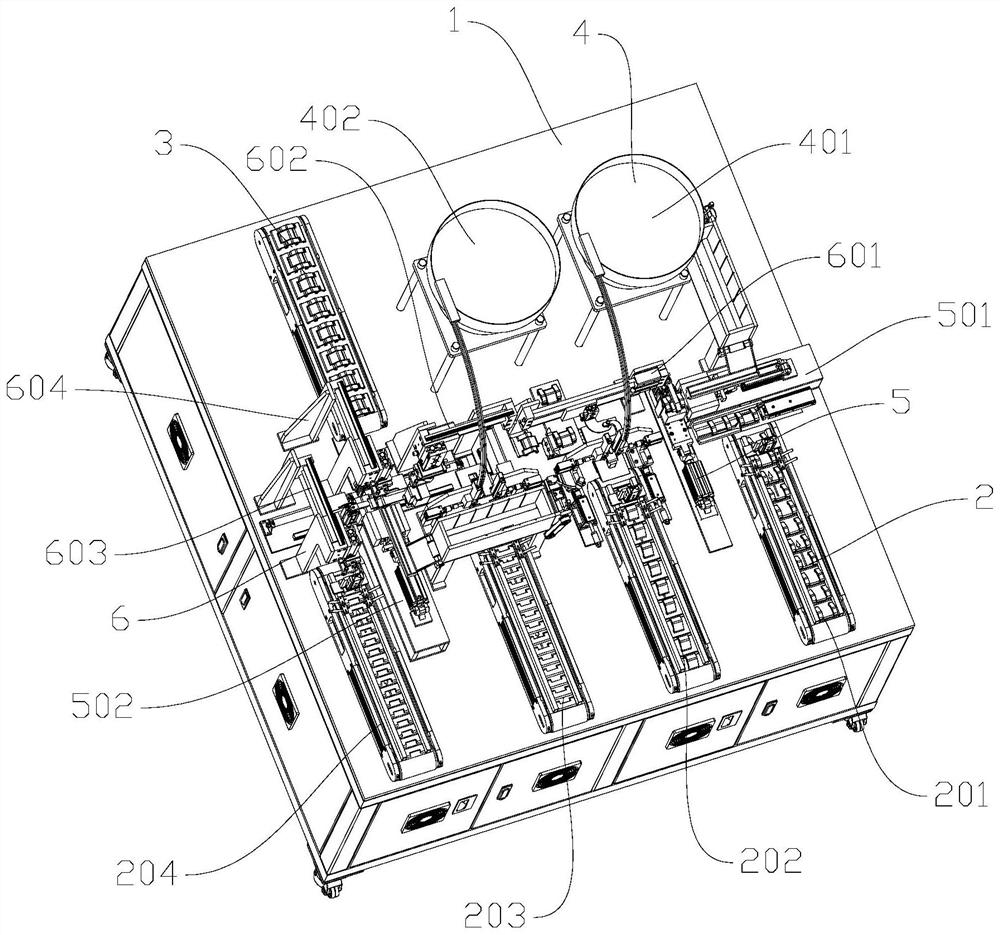

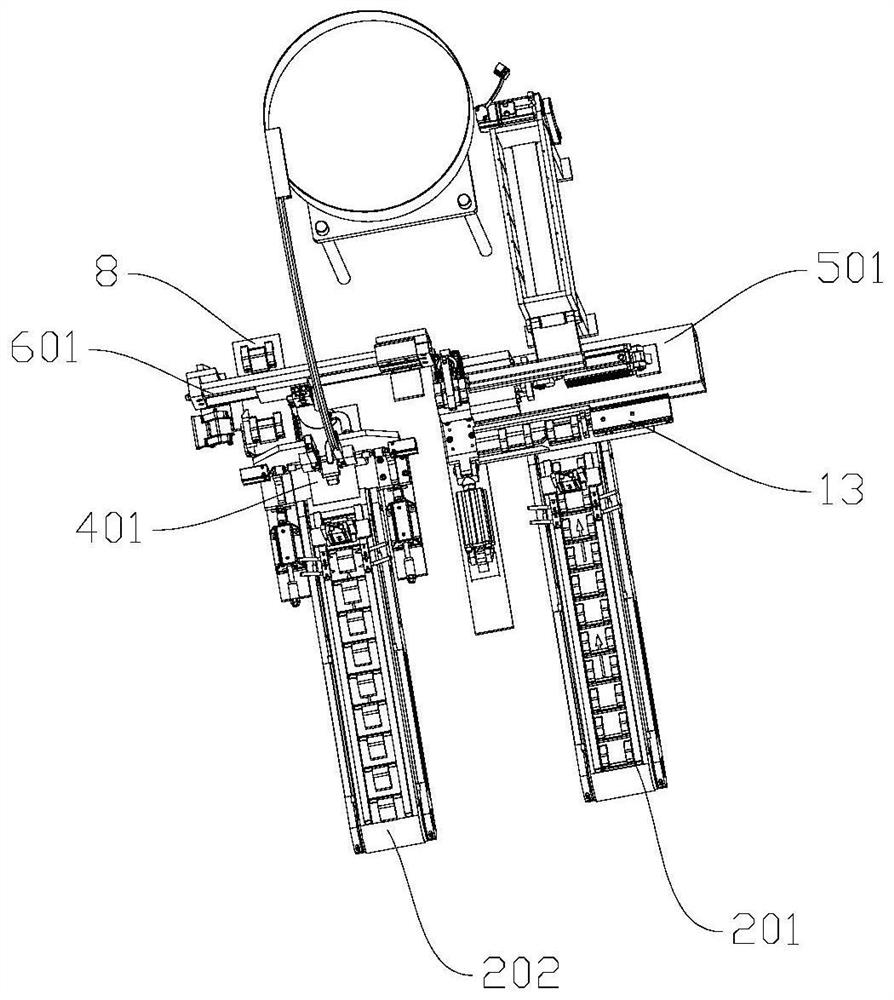

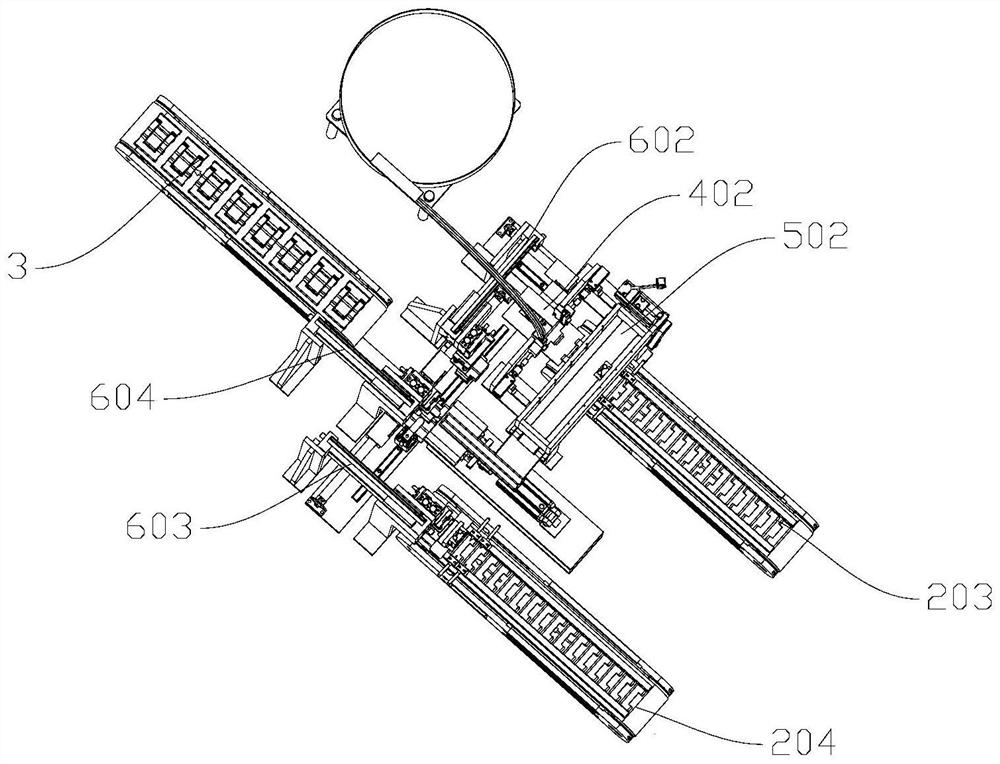

[0061] like Figure 1 to Figure 3 As shown, a hinge automatic assembly machine includes a machine platform 1, at least two feeding devices 2, a feeding device 3, a rotating sleeve pressing device 4 and a hinge pin assembly device 5; the feeding device 2, the lower The feeding device 3, the rotating shaft sleeve pressing device 4 and the hinge pin assembly device 5 are arranged on the machine platform 1, the feeding device 2 is used for conveying the hinge parts, and the rotating shaft sleeve pressing device 4 is used for turning the rotating shaft The sleeve is pressed into the assembly hole of the hinge part, the hinge pin assembly device 5 is used for assembling the hinge part and the pin shaft, and the unloading device 3 is used for conveying the assembled hinge part.

[0062] In the hinge automatic assembly machine provided by the embodiment of the present invention, the feeding device 2 supplies different hinge parts respectively, the rotating shaft sleeve pressing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com