Welding method of thermonuclear reactor experiment cladding modular unit assembly

An experimental cladding module and component assembly technology, applied in welding equipment, laser welding equipment, electron beam welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

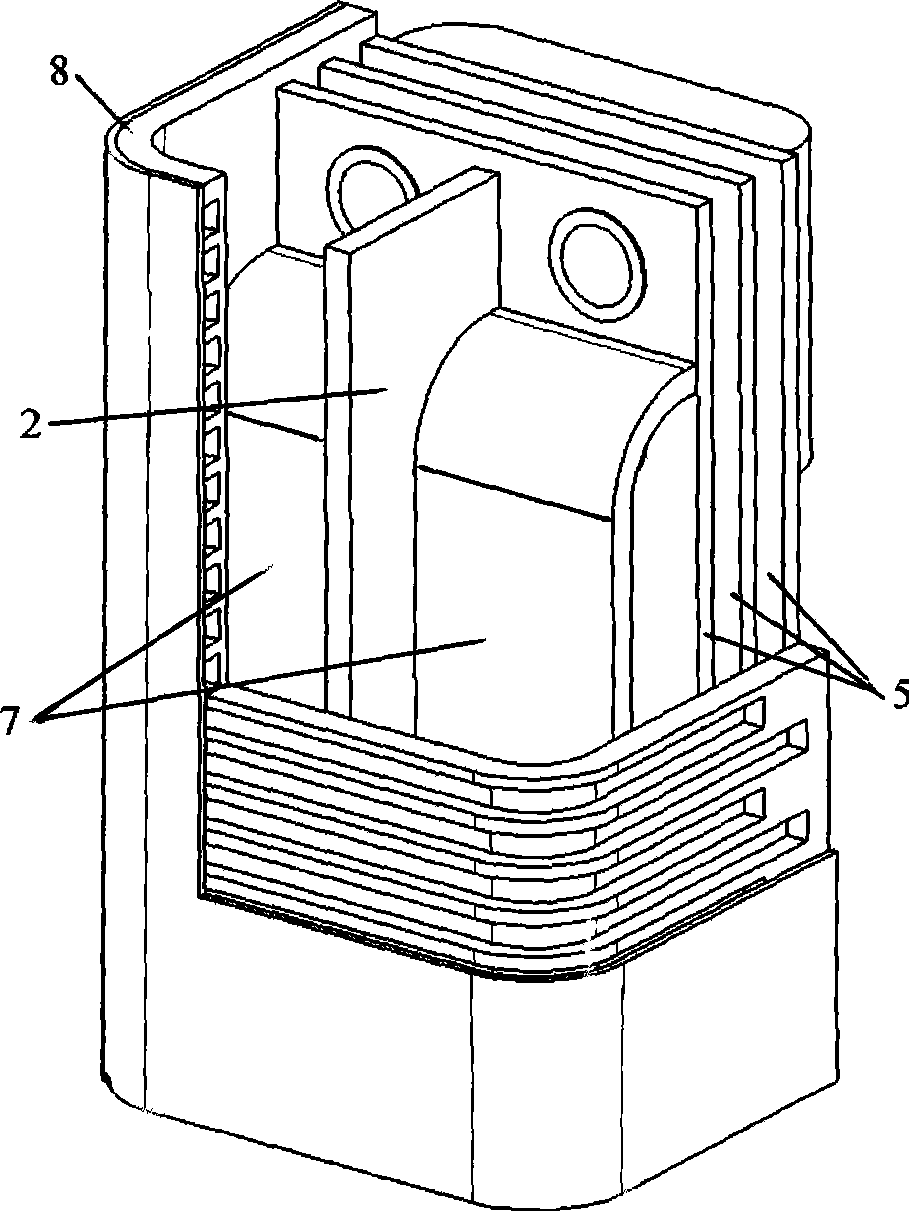

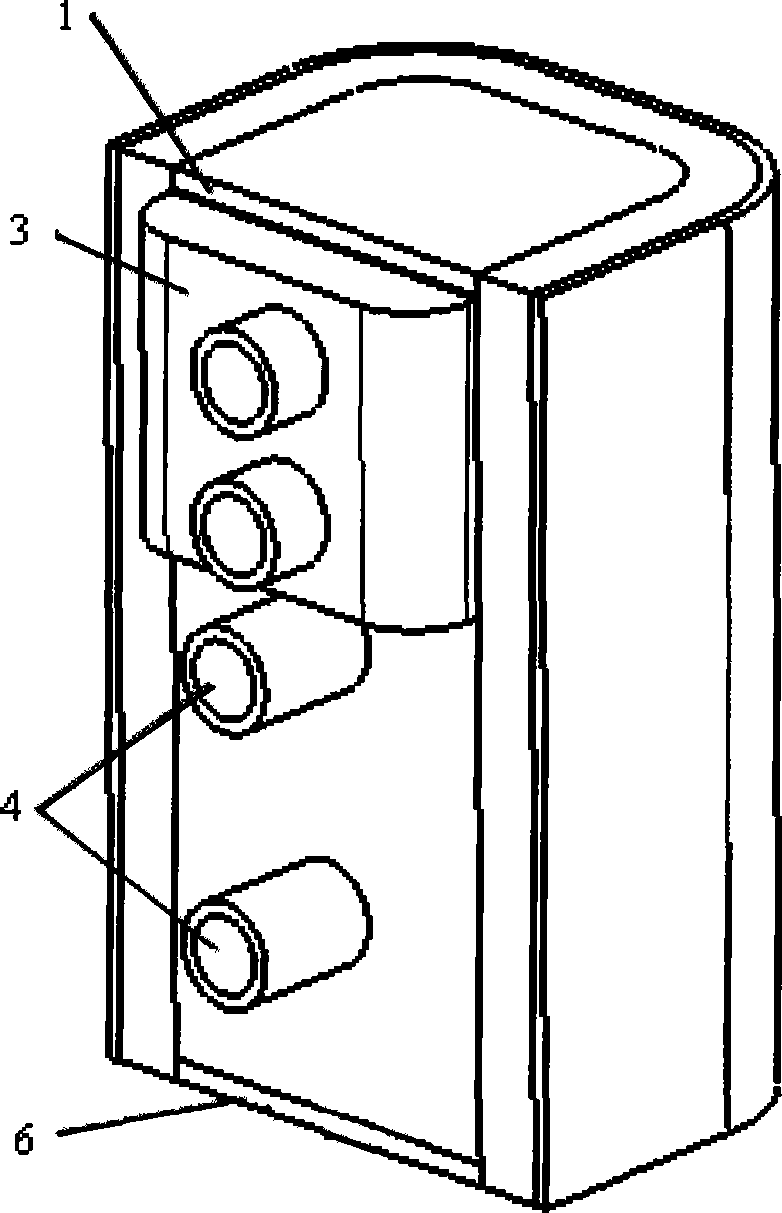

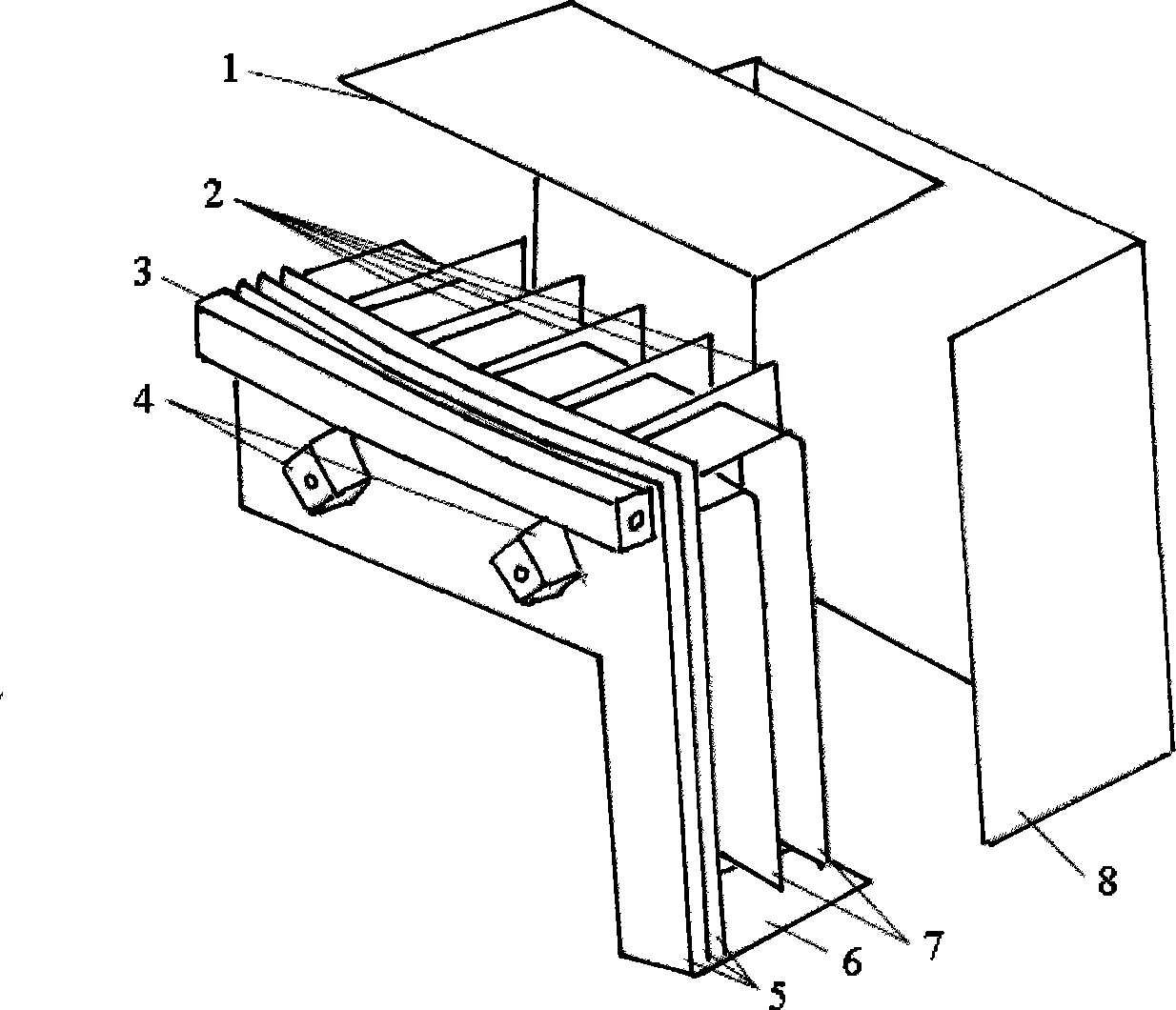

[0017] The welding method for assembling the fusion reactor experimental cladding module components includes the following steps in turn: a. welding the radial pole separator to the first wall; b. welding the ring pole in the area formed by the radial pole separator and the first wall Partition plate; c. Weld the upper cover plate and the lower cover plate to the first wall; d. Weld the back plate sequentially from the inside to the outside, and weld the branch pipes sequentially; e. Finally, weld the distribution / receiving box to the outermost back board. In this example laser welding is used.

[0018] The welding object in steps a and b is 10mm thick low-activation ferrite / martensitic steel; the welding parameters required for welding are: power 3-6kW; focus position 0-2mm; welding speed 0.3-2m / min, the protective gas is argon, and the flow rate of the protective gas is 1-101 / min.

[0019] The welding object in steps c and d is 5-35mm thick low-activation ferrite / martensi...

example 2

[0022] The welding method for assembling the fusion reactor experimental cladding module components includes the following steps in turn: a. welding the radial pole separator to the first wall; b. welding the ring pole in the area formed by the radial pole separator and the first wall Partition plate; c. Weld the upper cover plate and the lower cover plate to the first wall; d. Weld the back plate sequentially from the inside to the outside, and weld the branch pipes sequentially; e. Finally, weld the distribution / receiving box to the outermost back board. In this example electron beam welding is used.

[0023] The welding object in steps a and b is 10mm thick low-activation ferrite / martensitic steel; the welding parameters required for welding are: acceleration voltage is 55-60kV; electron beam current is 20-90mA; focusing current is 650-800mA ; Working distance is 140~200mm; welding speed is 10~14mm / s; vacuum degree is 5×10 -2 ~5×10 -3 Pa.

[0024] The welding object in ...

example 3

[0027] The welding method for assembling the fusion reactor experimental cladding module components includes the following steps in turn: a. Welding a radial pole separator to the first wall; b. After step a is completed, it is composed of the radial pole separator and the first wall 2 areas, weld 1 ring pole separator in each area, weld 2 ring pole separators in total; d, weld 3 back plates sequentially from inside to outside, and weld branch pipes in sequence. Other conditions and steps are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com