Polar pole die

A mold and pole technology is applied to the field of hand-casting molds for battery poles, which can solve the problems of time-consuming and laborious, mold-opening force and large mold-opening stroke, and achieve the effect of simple structure and operation, reducing production cycle and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

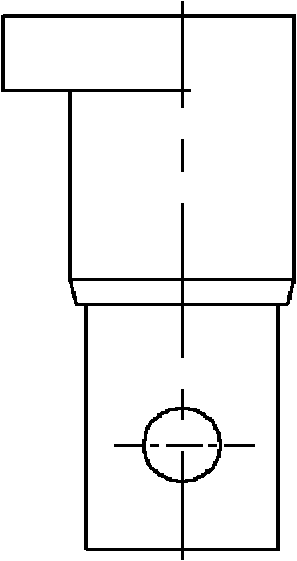

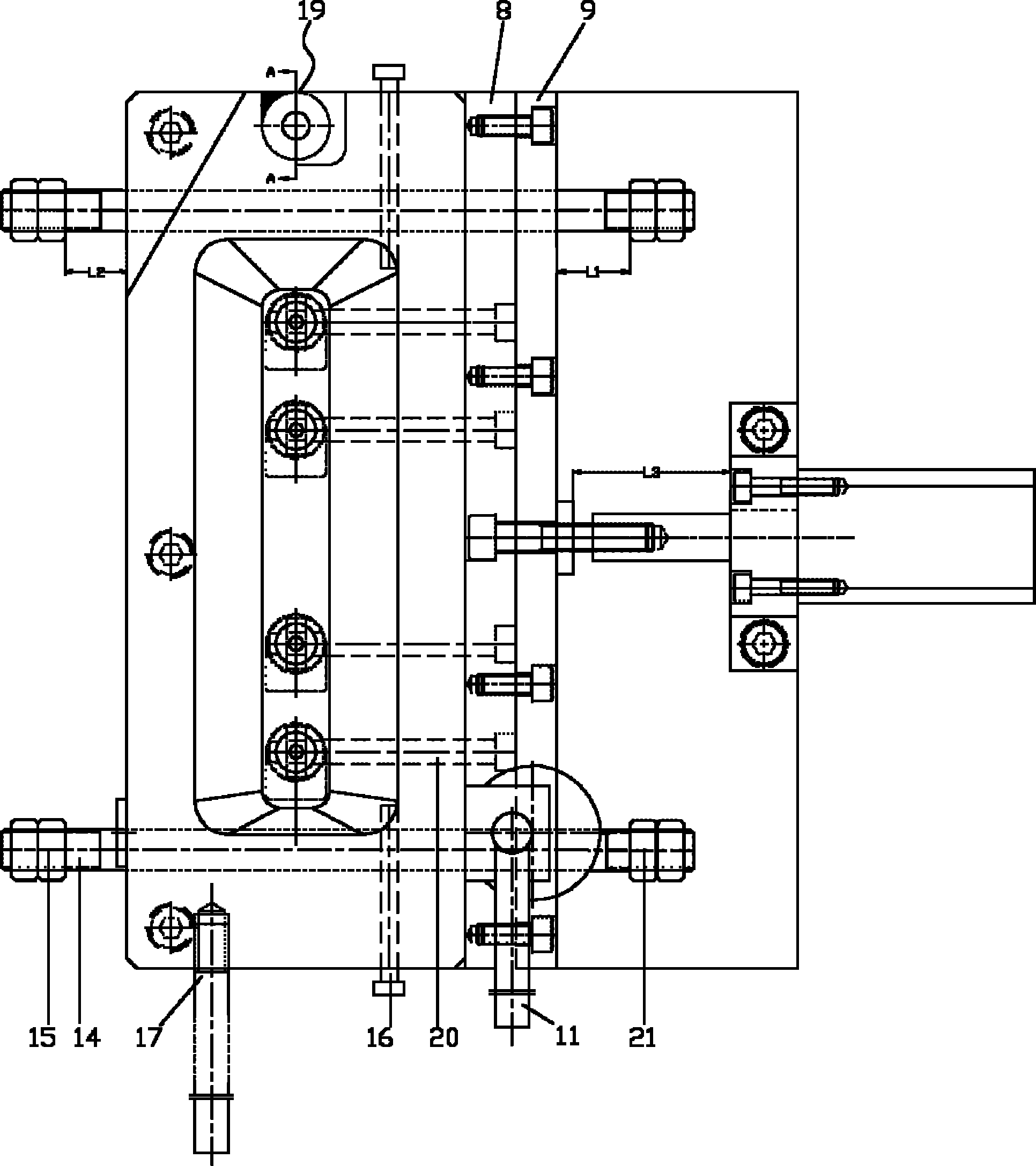

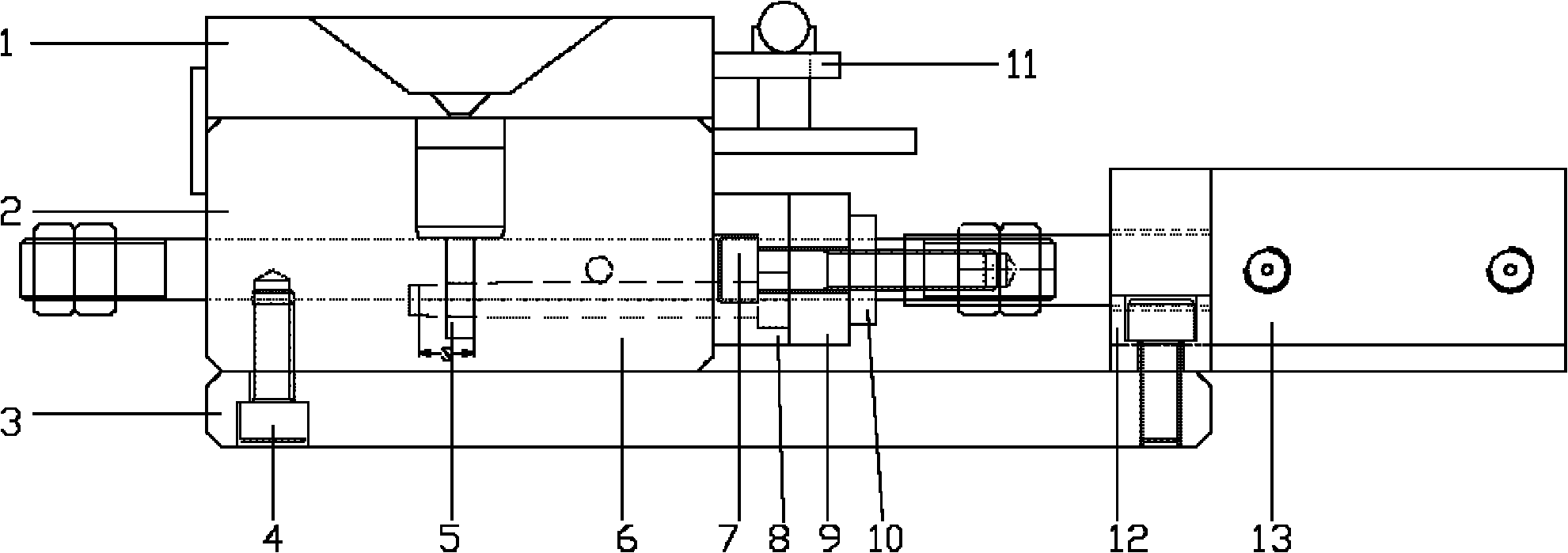

[0019] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0020] refer to figure 2 and image 3 As shown, a pole mold includes a base plate 3, a sprue plate 1, and left and right templates 2 and 6 between the base plate 3 and the sprue plate 1; the left template 2 is fixed on the base plate 3, and the right template 6 There is at least one insert pin 20 for side core pulling; a horizontal drive mechanism is also provided on the right side of the right template 6 on the bottom plate 3, and the output end of the horizontal drive mechanism is fixedly connected to the insert pin 20 through a connecting plate; A mold opening limiting mechanism is also arranged on the right template 6, and the mold opening limiting mechanism cooperates with the connecting plate and the left template 2 respectively.

[0021] During implementation, the horizontal drive mechanism can use a cylinder.

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com