Crimping and rebounding control method of lateral wall of advanced high-strength steel stamping part

A control method and high-strength steel technology, applied in the field of stamping forming, can solve problems such as uneven stress distribution, difficulty in assembling parts, and difficult control of forming quality, and achieve the effect of improving forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

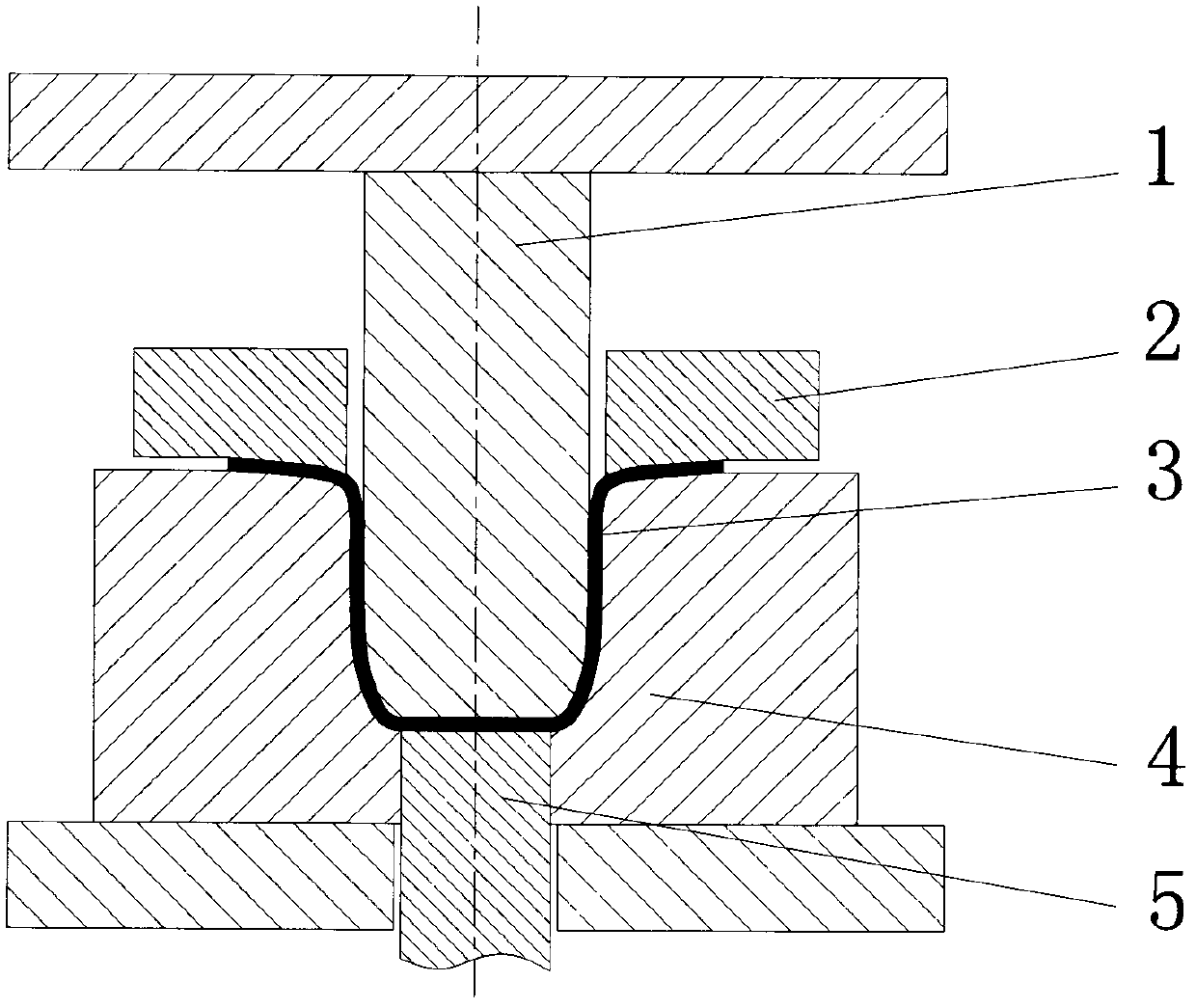

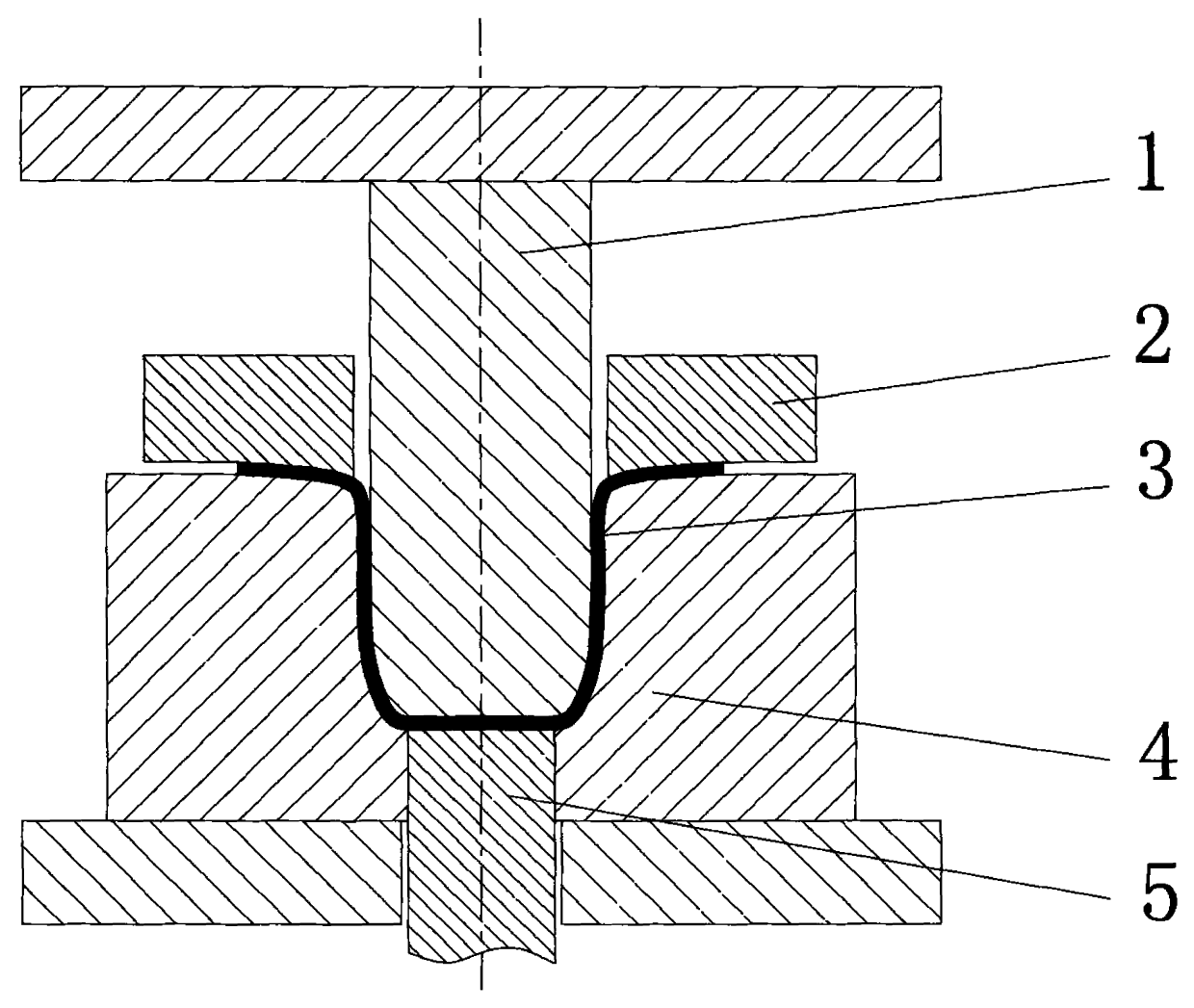

[0011] The content of the present invention and its specific implementation will be further described in conjunction with the accompanying drawings.

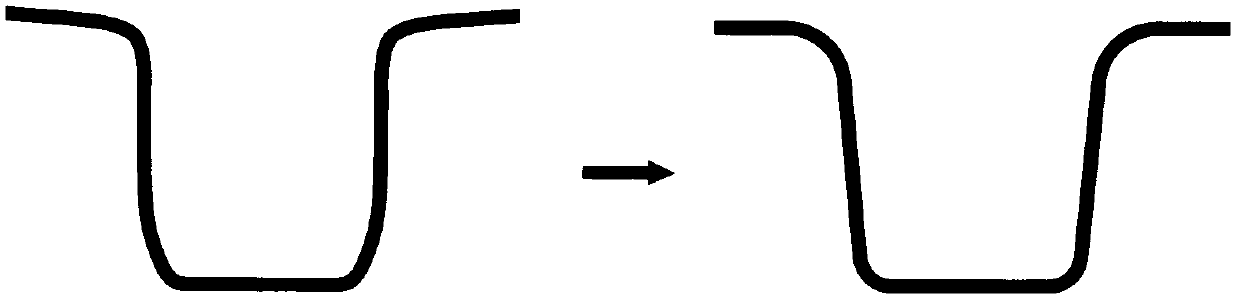

[0012] Through the numerical simulation of the advanced high-strength steel cap-shaped stamping parts, there is a preliminary identification of the side wall curling and the flange edge sinking, the mold in the model is modified, and the stamping forming simulation is performed using the modified mold And springback simulation, calculate the pre-form bending radian and die face bevel angle required to obtain accurate size parts.

[0013] According to the simulation results, the mold is processed, the side walls of the convex and concave molds are processed into arc-shaped surfaces, and the flange side mold faces are inclined upwards, and the stamping test is carried out. After the end, the springback is balanced due to the pre-reverse deformation stress The side wall is curled, so that the side wall tends to be straight and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com