Single mass plate triaxial micro-mechanical accelerometer

An accelerometer and axial acceleration technology, which is applied in the field of micro-inertial devices, can solve problems such as inability to be sensitive to linear acceleration, achieve the effects of reducing volume and weight, avoiding assembly problems, and reducing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

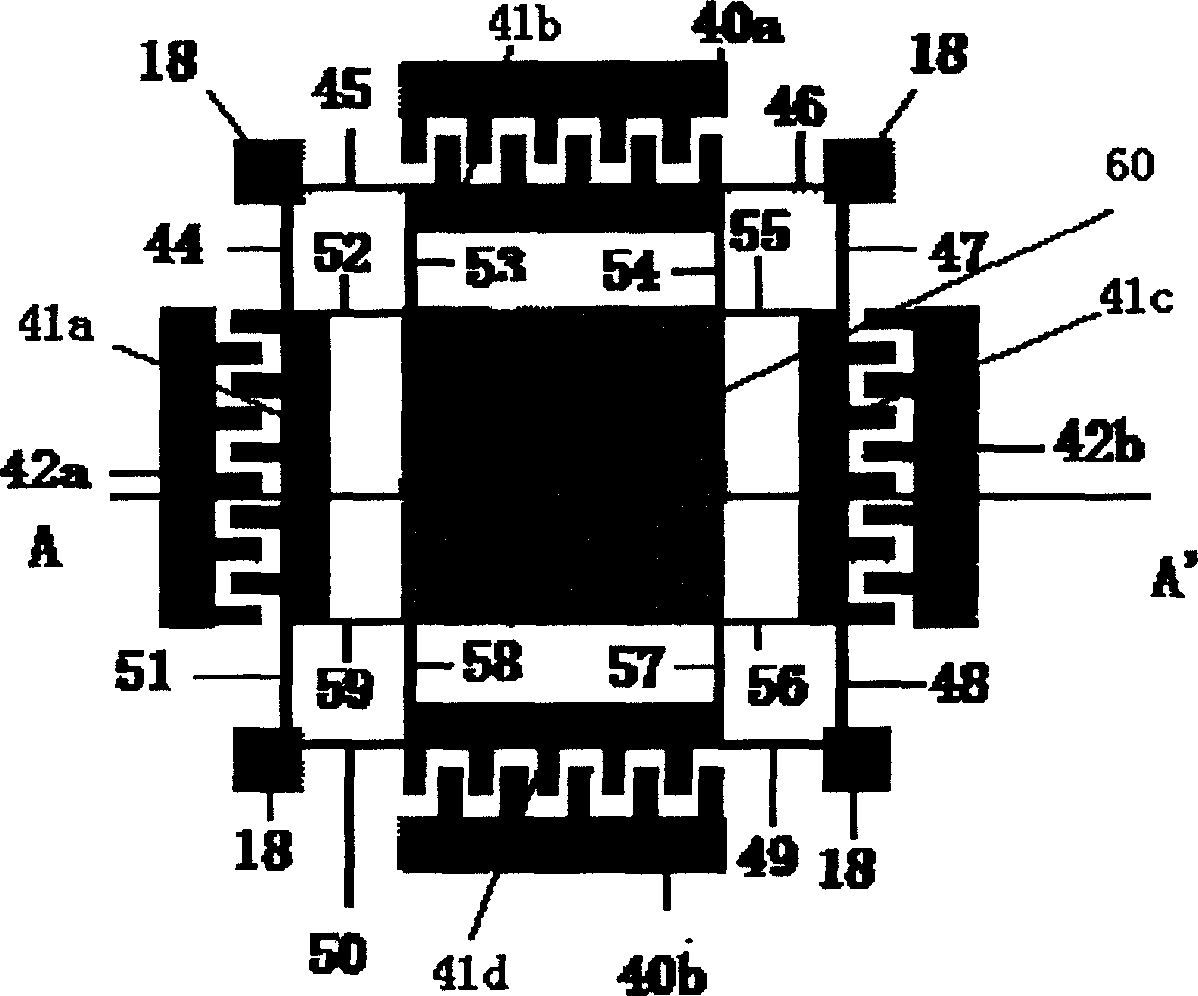

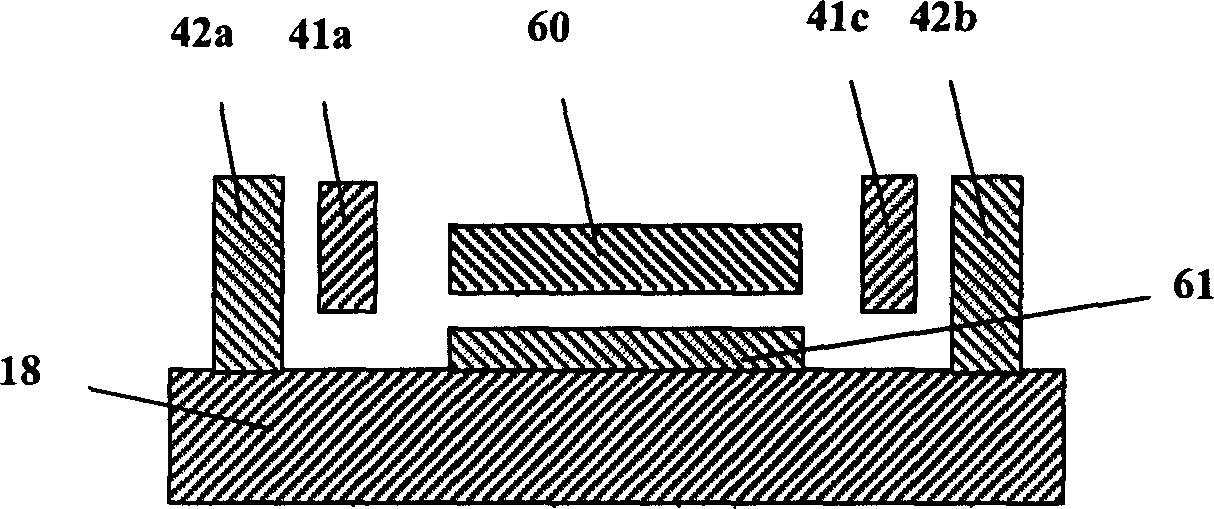

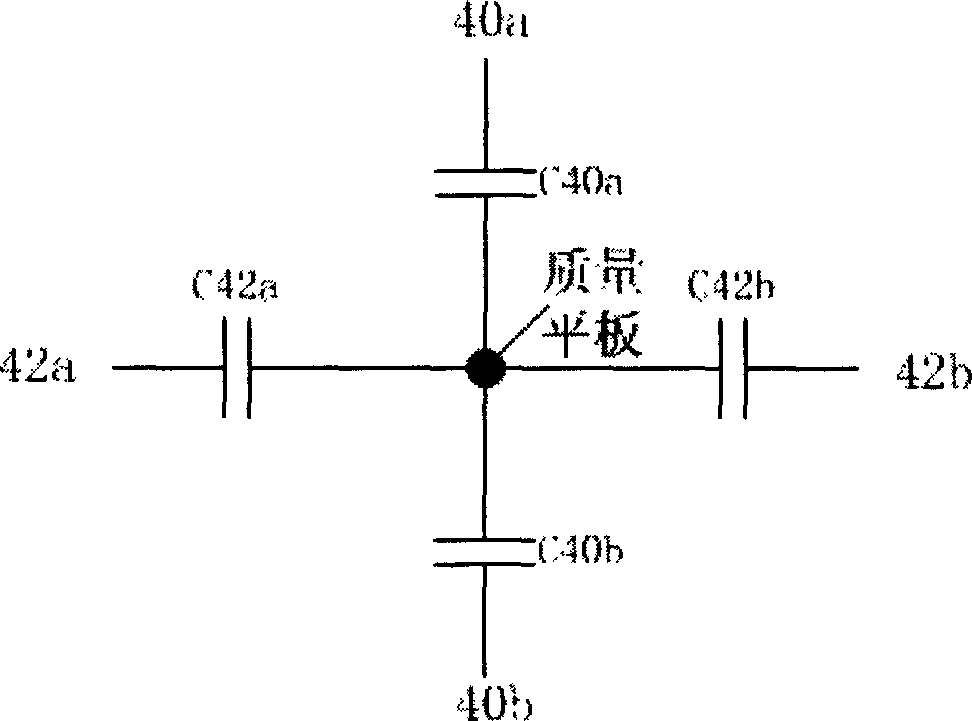

[0014] refer to Figure 1~4 . The present invention adopts a symmetrical structure, and the mass plate 60 passes through the outer beam I44 in the y direction, the outer beam I45 in the x direction, the outer beam II46 in the x direction, the outer beam II47 in the y direction, the outer beam III in the 48.y direction, and the outer beam III in the x direction. III, 50. Outer beam IV in x direction, 51. Outer beam IV in y direction, 52. Inner beam I in x direction, I53 inner beam in y direction, II54 inner beam in y direction, II55 inner beam in x direction, III56 inner beam in x direction, The support beam composed of the inner beam III57 in the y direction, the inner beam IV58 in the y direction and the inner beam IV59 in the x direction is suspended and fixed to the base 18 . Four groups of comb teeth protrude from the surroundings of the quality plate 60: comb electrode I41a, comb electrode II41b, comb electrode III41c, and comb electrode IV41d, which are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com