A side-span structure of a prefabricated electronic factory building and its construction method

An electronic workshop and prefabricated technology, applied in industrial buildings, building components, building structures, etc., can solve the problems of low construction efficiency, huge consumption of social resources, and poor assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

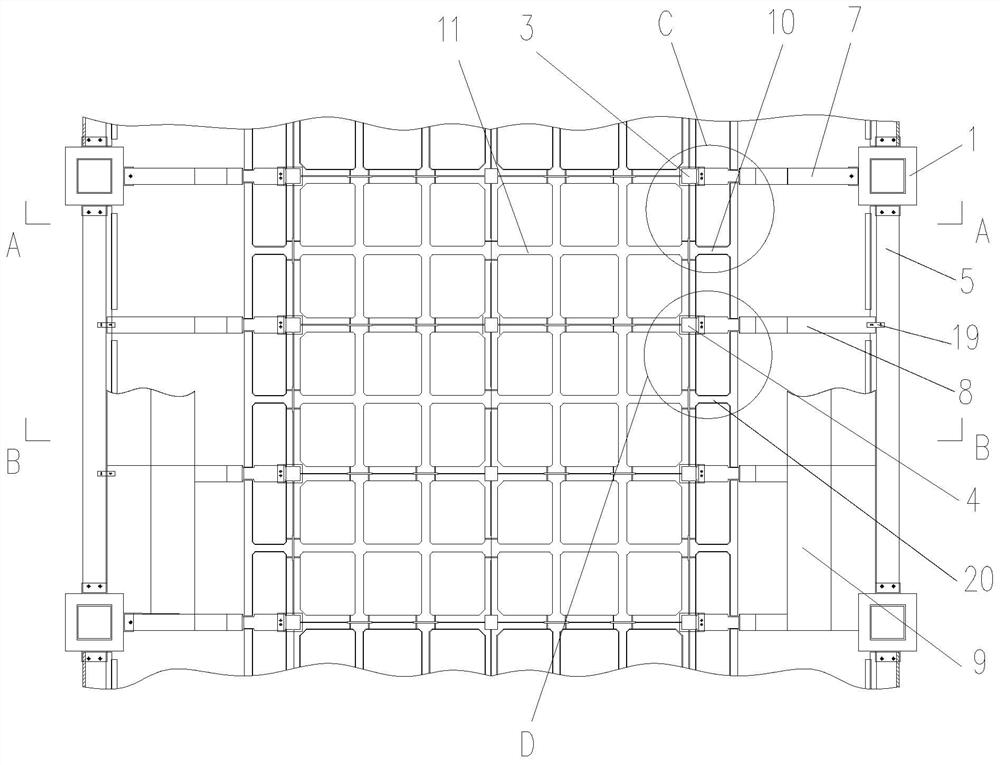

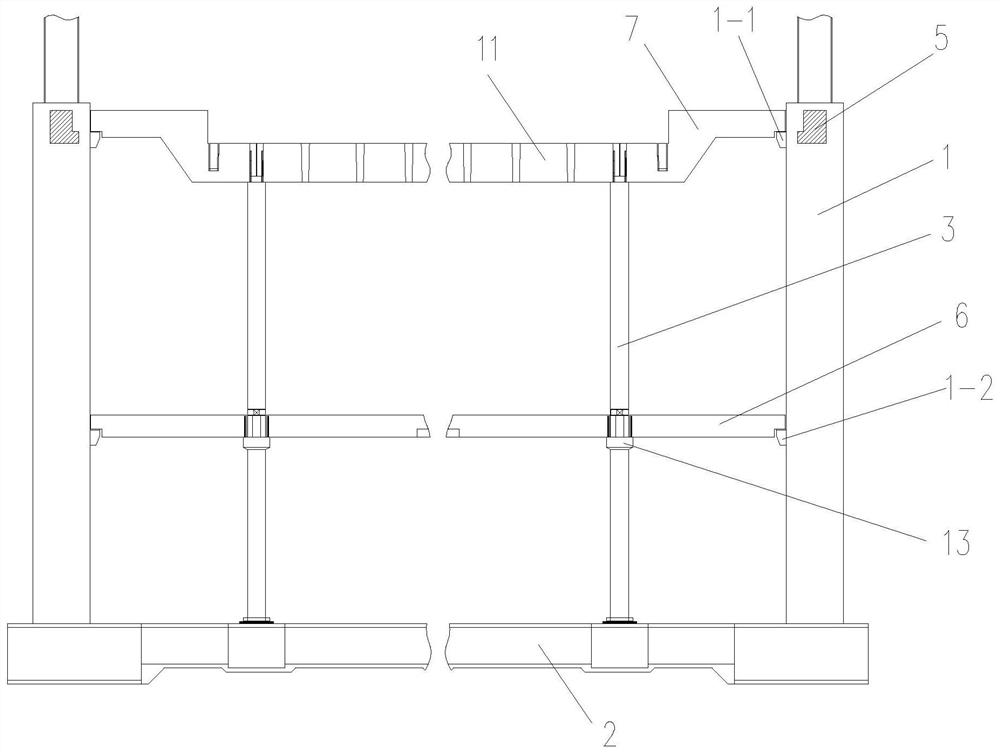

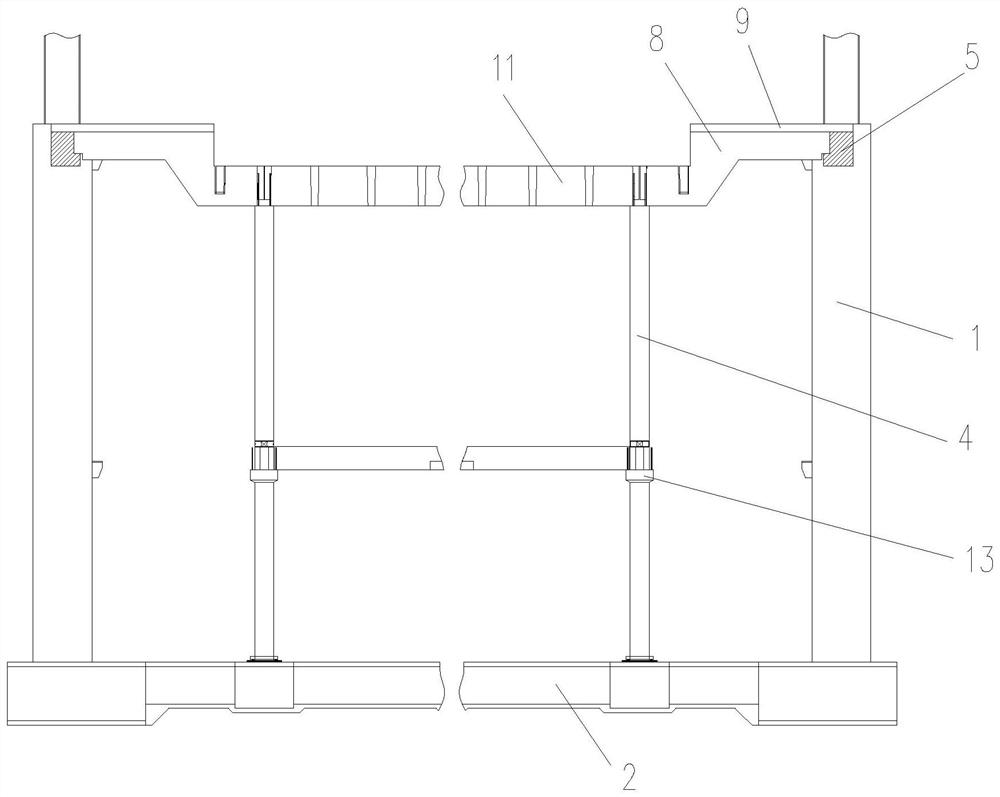

[0077] such as Figure 1 、 Figure 2 and Figure 3 A side span structure of an assembled electronic factory building is shown, which comprises a plurality of first prefabricated PC columns 3 arranged in a row on the inner side of a steel structure and a plurality of second prefabricated PC columns 4 arranged in a row between two adjacent first prefabricated PC columns 3, wherein the number of the first prefabricated PC columns 3 and the steel columns 1 are equal and correspond one to one, and the structures of the first prefabricated PC columns 3 and the second prefabricated PC columns 4 are completely the same. The height of the first prefabricated PC column 3 and the height of the second prefabricated PC column 4 are both lower than that of the steel column 1, the top of the first prefabricated PC column 3 and the top of the second prefabricated PC column 4 are both provided with vertical embedded connecting steel bars 12, and a longitudinal prefabricated rectangular PC beam 5 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com