Welding manipulator based on six-axis robot for pole needle and bridge belt welding

A six-axis robot and welding manipulator technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of misjudgment of bridge belt qualification and unguaranteed quality, so as to reduce errors and occupy space Small, Highly Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The content of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

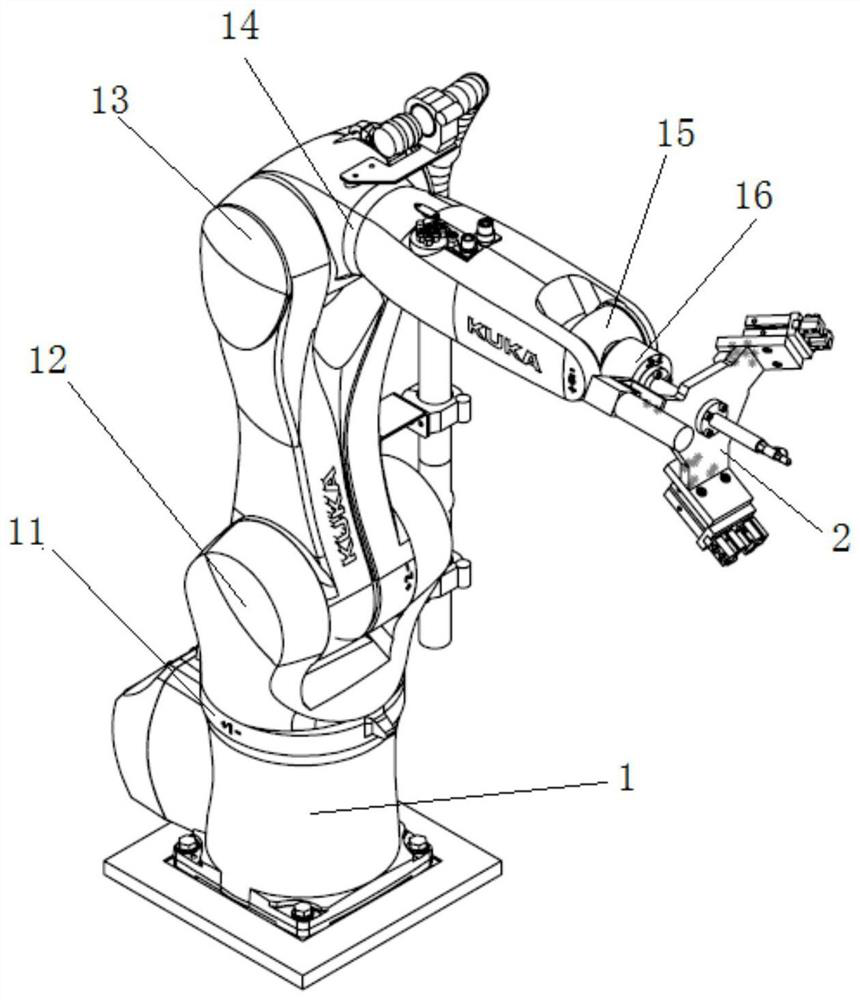

[0034] like figure 1 As shown in the figure, a welding manipulator based on a six-axis robot for sealing body poles and bridges includes a six-axis robot 1 and a welding fixture assembly 2 arranged on the output shaft 16 of the six-axis robot 1; The shafts are the first shaft 11 , the second shaft 12 , the third shaft 13 , the fourth shaft 14 , the fifth shaft 15 and the output shaft 16 , which are arranged in sequence.

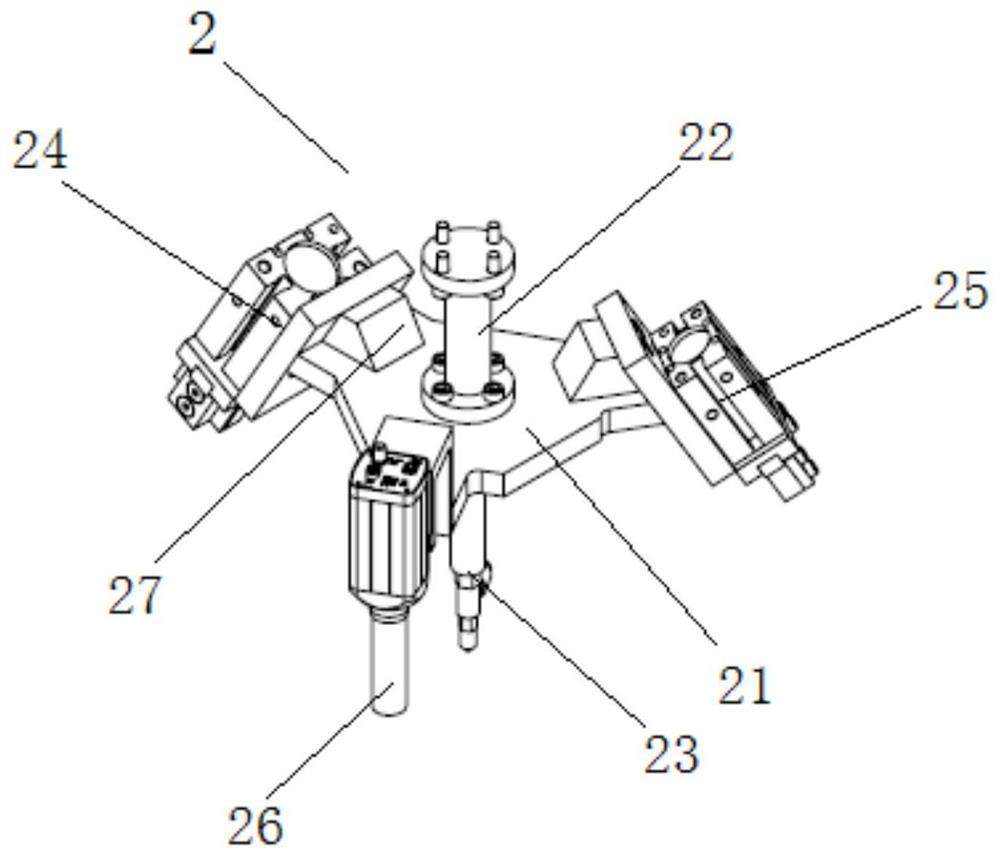

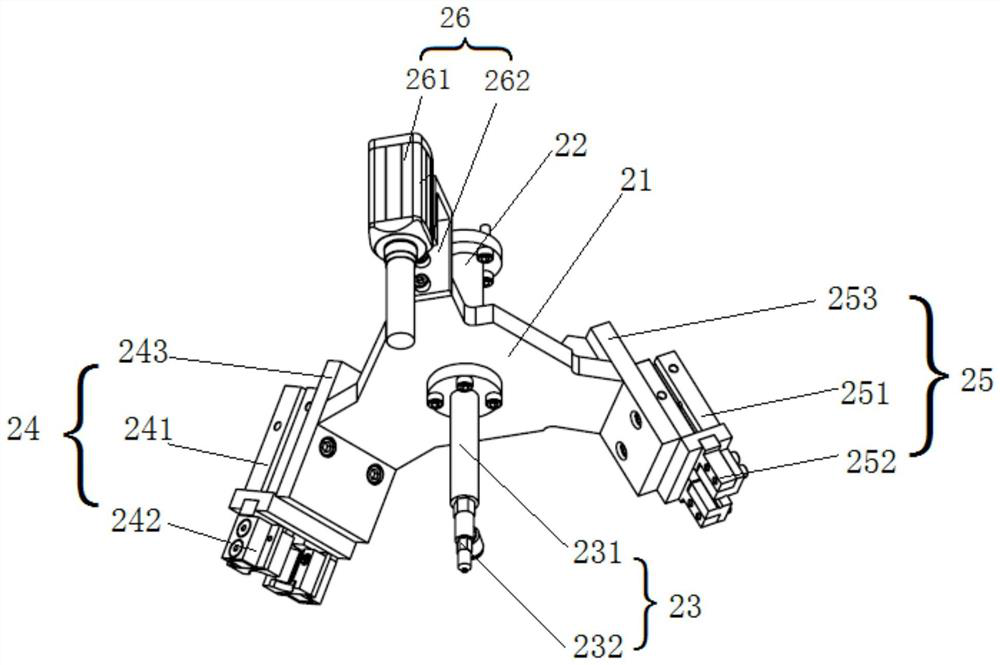

[0035] like figure 2 and image 3 As shown, the welding fixture assembly 2 includes a welding fixture connecting plate 21, a connecting flange 22, a bridge belt suction fixture 23, a sealing body grasping fixture 24, a welding pin grasping fixture 25, and a vision system 26. The flange 22 is located in the middle of the upper surface of the welding jig connecting plate 21, the bridge belt suction jig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com