Patents

Literature

65results about How to "Improve picking accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

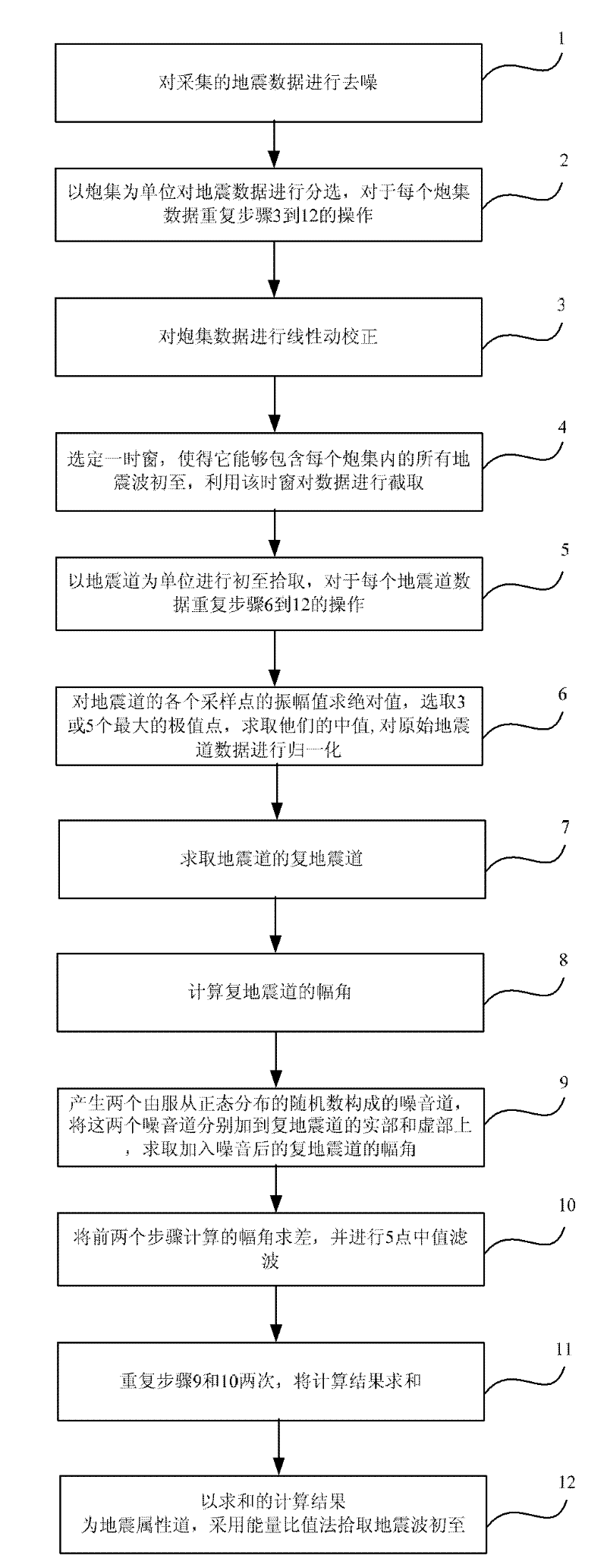

Method for picking seismic wave first break

ActiveCN102243320AImprove noise immunityImprove picking accuracySeismic signal processingSeismic waveRatio method

The embodiment of the invention provides a method for picking a seismic wave first break. The method comprises the following steps of: forming a new seismic attribute trace based on a complex seismic trace noise-adding method; and picking the seismic wave first break by using an energy ratio method. Compared with the conventional energy ratio method of the seismic attribute trace (an amplitude absolute value or an amplitude envelope), the method for picking the seismic wave first break has the characteristics of high anti-noise capacity and high picking accuracy.

Owner:PETROCHINA CO LTD

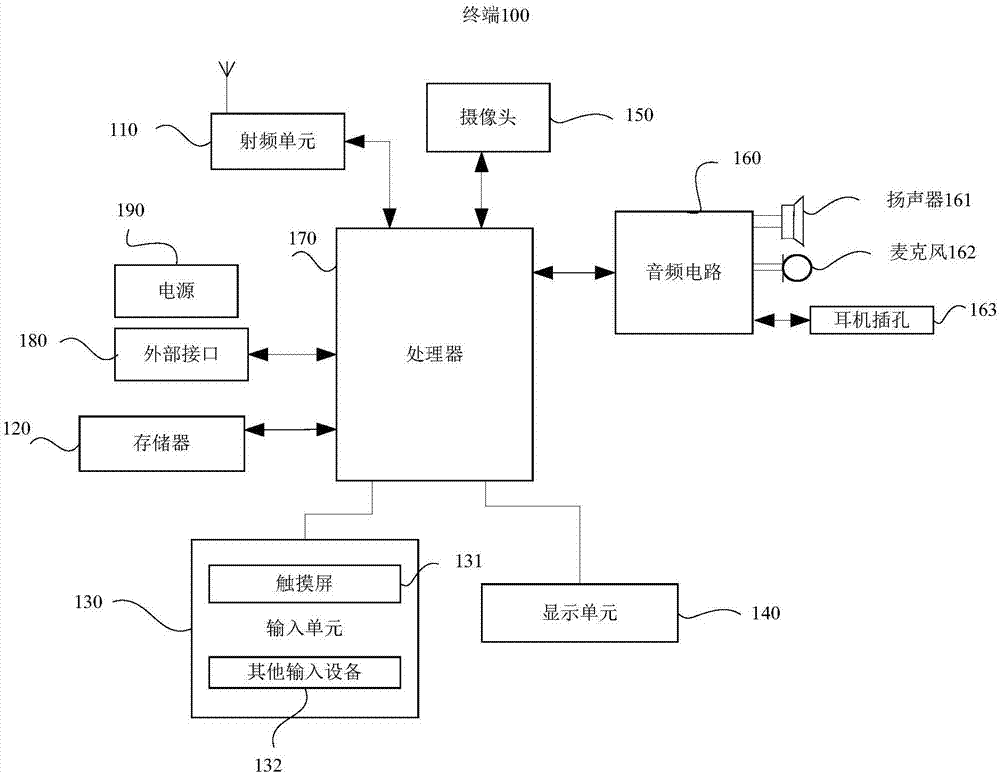

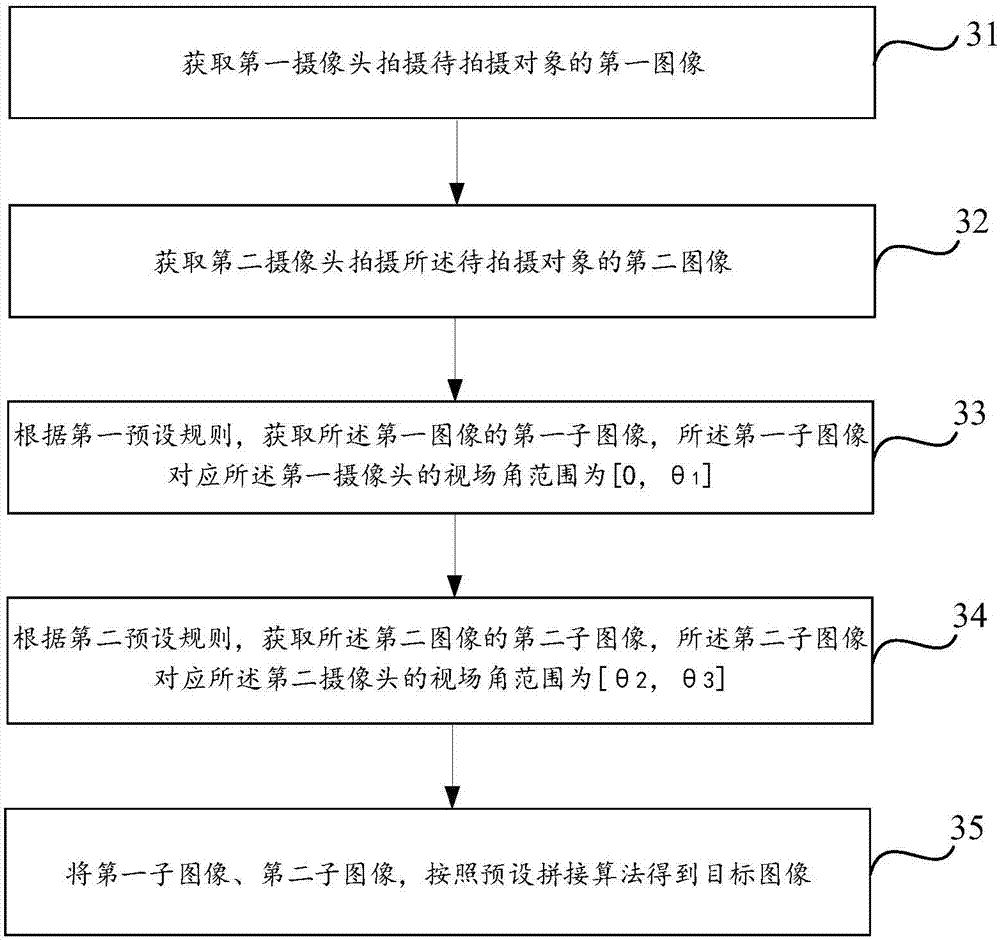

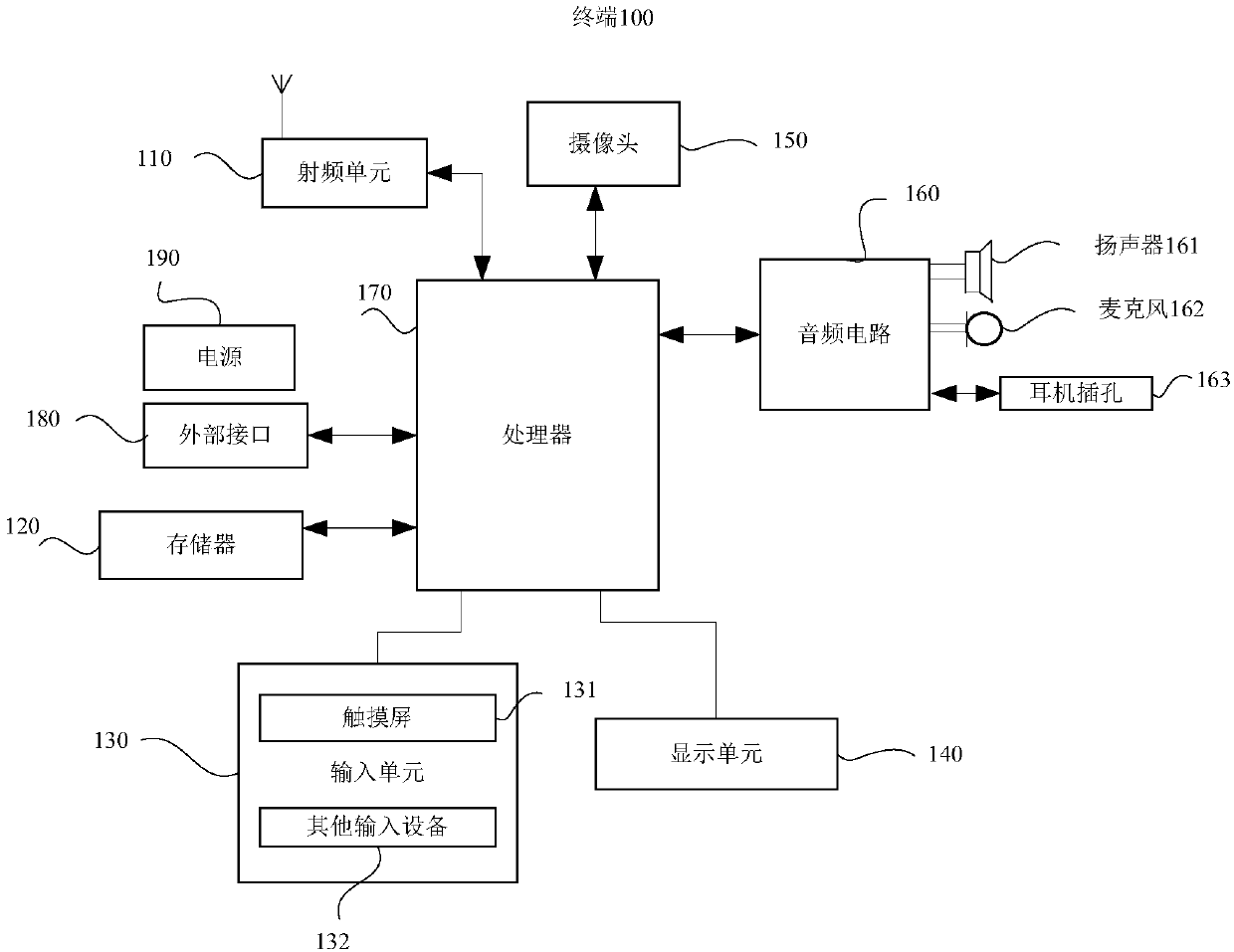

Image processing method, apparatus and equipment

InactiveCN107295256AReduce design difficultyReduce manufacturing difficultyTelevision system detailsColor television detailsVisual field lossImaging processing

The invention discloses an image processing method, apparatus and equipment. The image processing method is applied to a terminal with two specifically manufactured cameras, wherein the first camera and the second camera are customized especially so as to sacrifice the definition of images in the local visual field angle range as the cost; and a super large aperture is realized through the current technology, so that the taken images of a part of areas can satisfy the quality demand of the super large aperture. The image processing method includes the steps: acquiring the first sub image of an object to be taken by the first camera, wherein the corresponding visual field angle range is [0, theta1]; acquiring the second sub image of the object to be taken by the second camera, wherein the corresponding visual field angle range is [theta2, theta3] and the quality of the first sub image and the quality of the second sub image can satisfy the definition demand of the super large aperture; and splicing and fusing the first sub image with the second sub image to obtain a target image satisfying the super large aperture in a greater visual field angle range.

Owner:HUAWEI TECH CO LTD

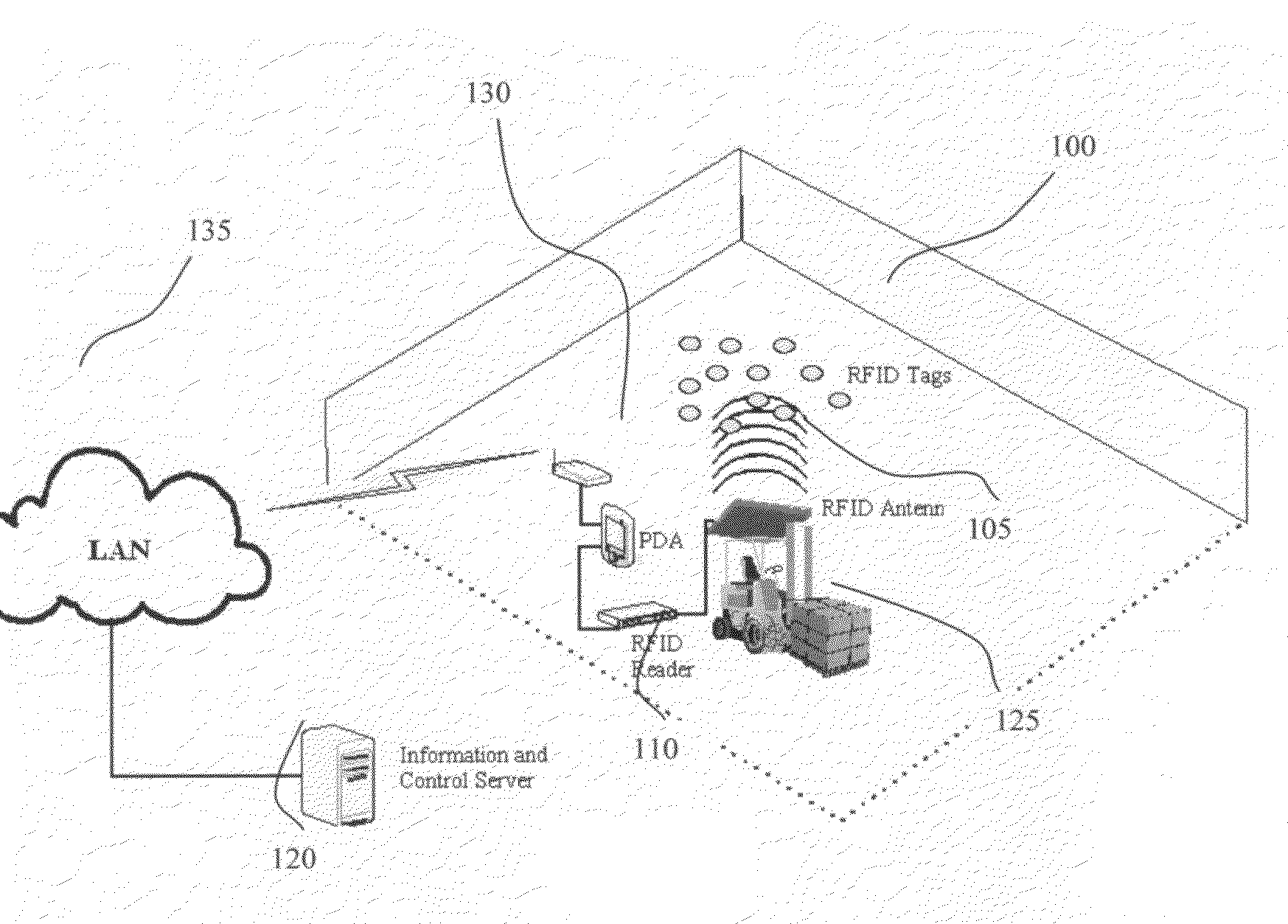

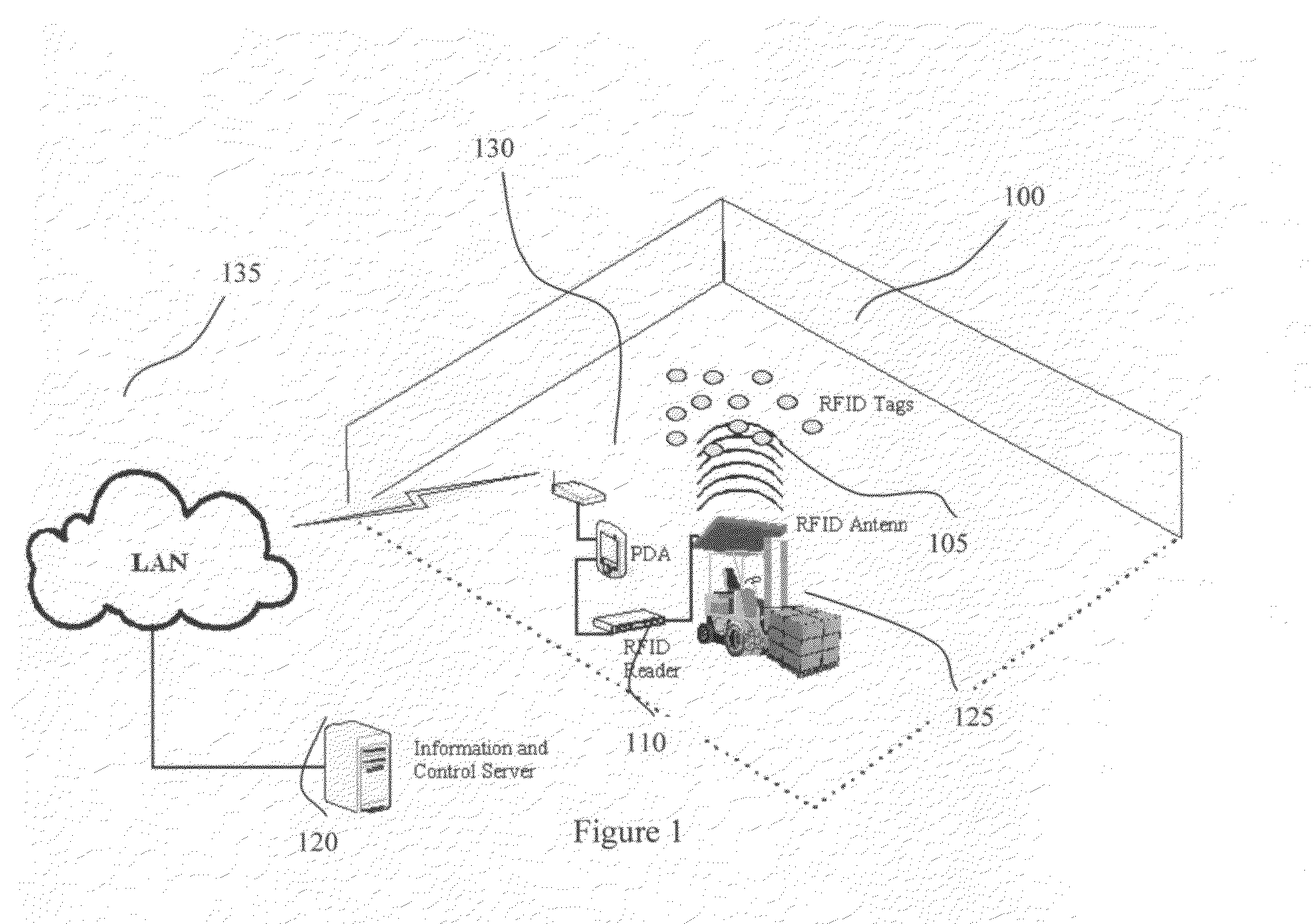

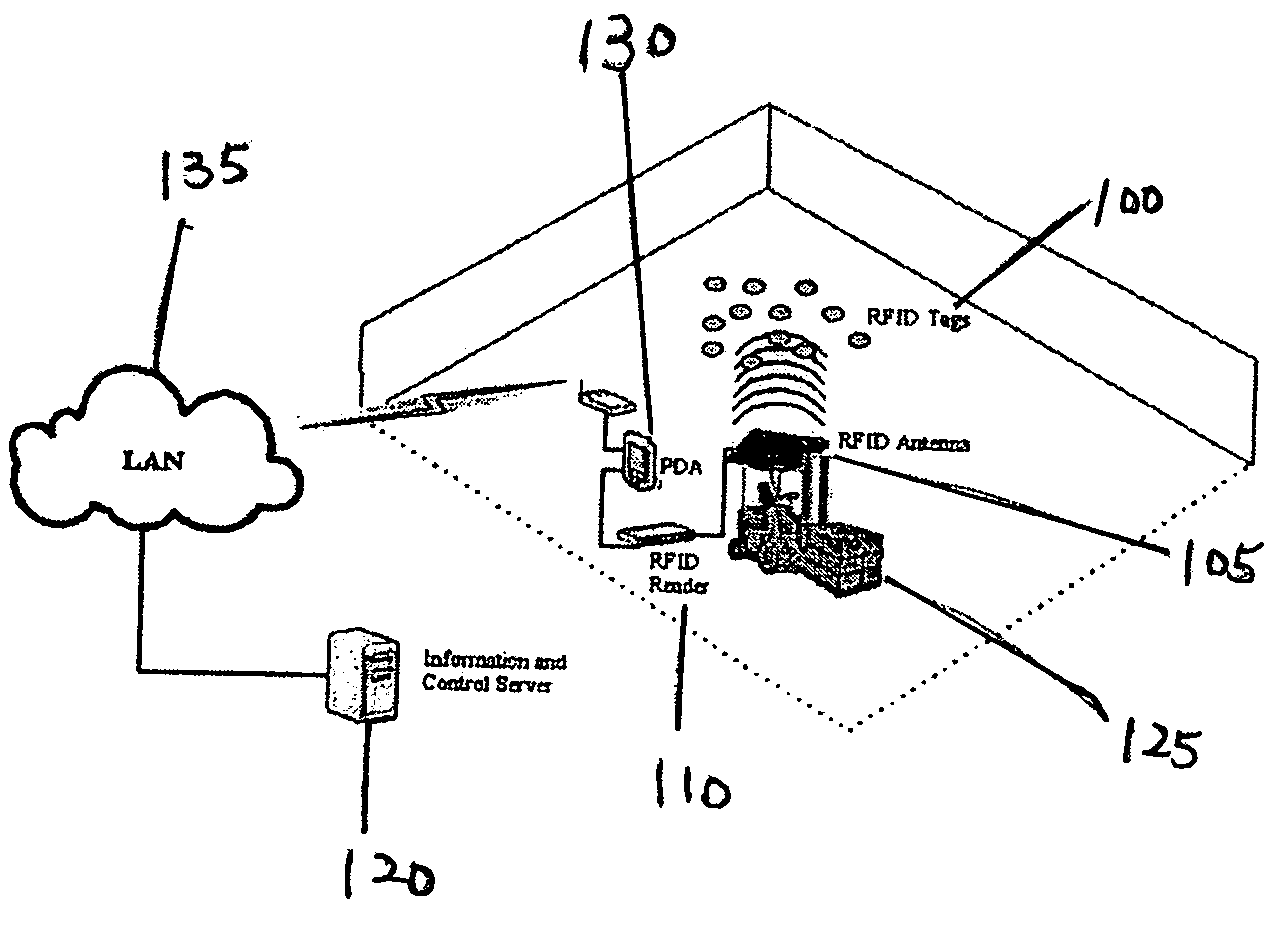

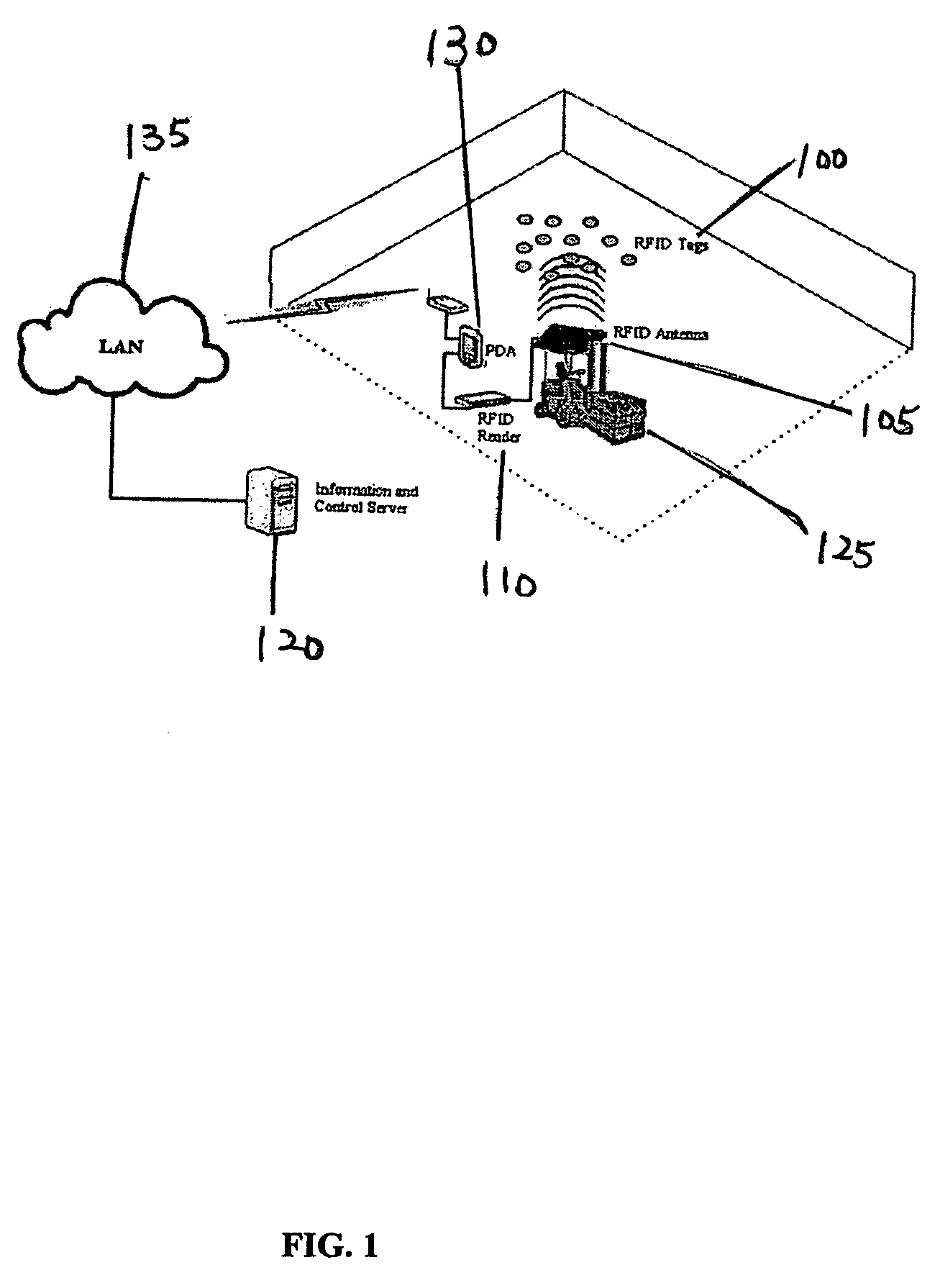

Method for precise in-house positioning

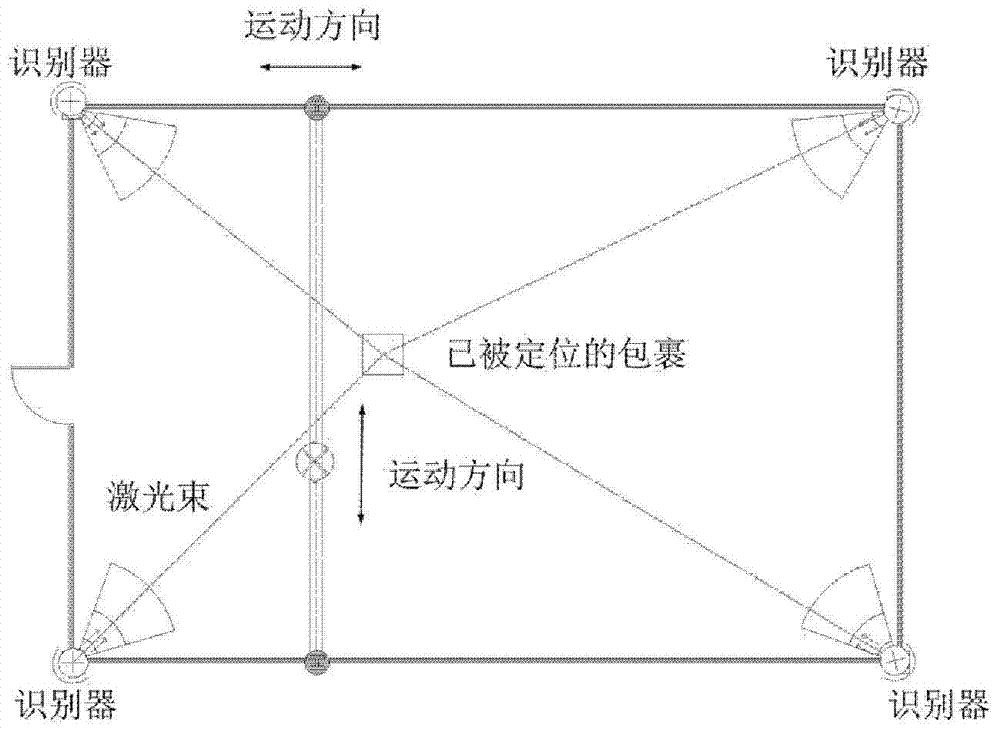

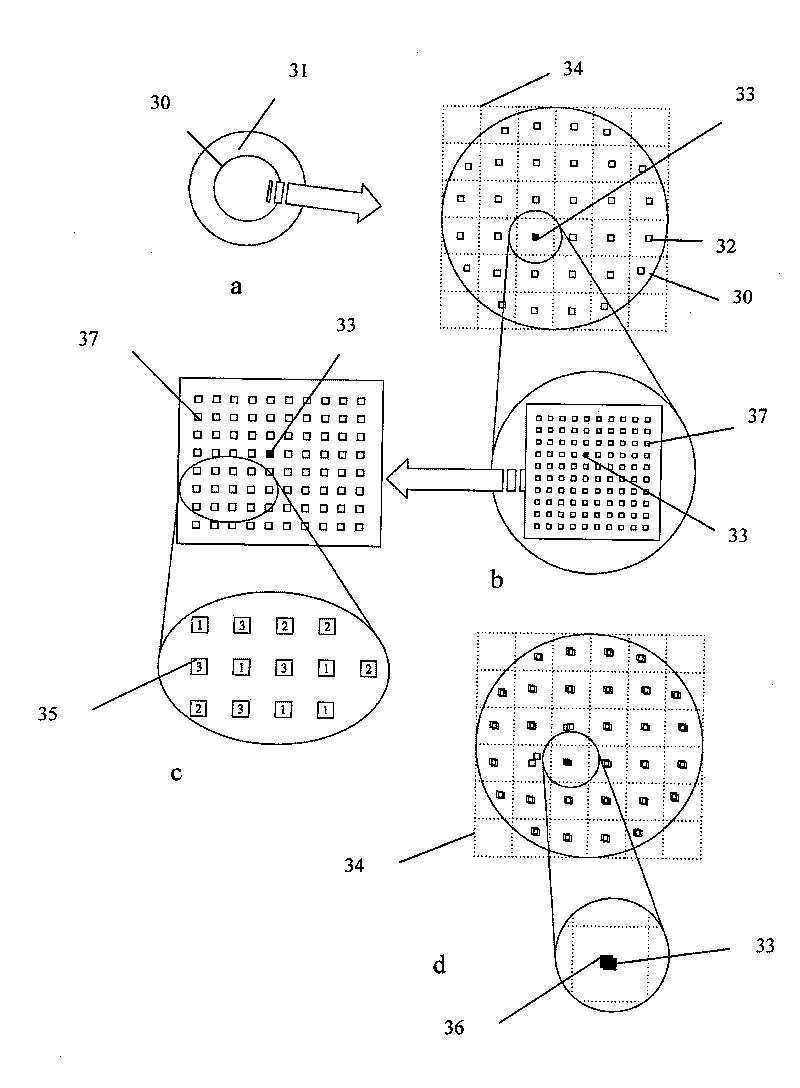

InactiveUS7598865B2Improve picking accuracyImprove space utilizationPosition fixationElectric/electromagnetic visible signallingClassification methodsComputer science

A robust system, apparatus, and method for precise in-house positioning utilizing RFID (Radio Frequency Identification) technology are described in this invention. The in-house environment is partitioned into separate locations, and a set of RFID tags are scattered in the environment. Reading patterns of RFID tags are collected at each location by an RFID reader as samples. Pattern recognition and classification methods are used, when human, vehicle, or other carrier move around the environment with an RFID reader to estimate its physical location based on the reading pattern. The precision can be within one meter. The method is adaptive to different tag distribution, reader range, defective tags, and other physical constraints.

Owner:THE HONG KONG UNIV OF SCI & TECH

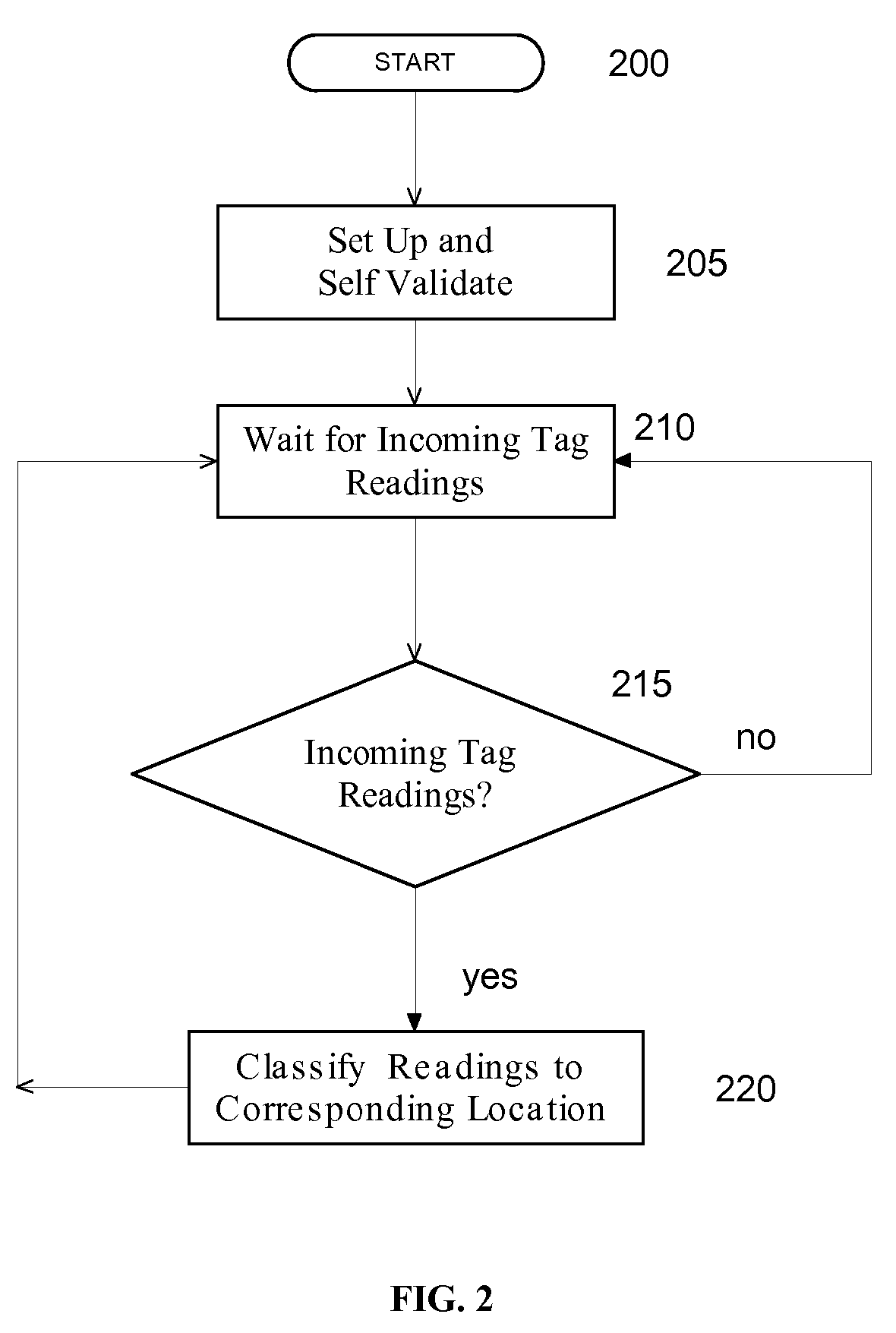

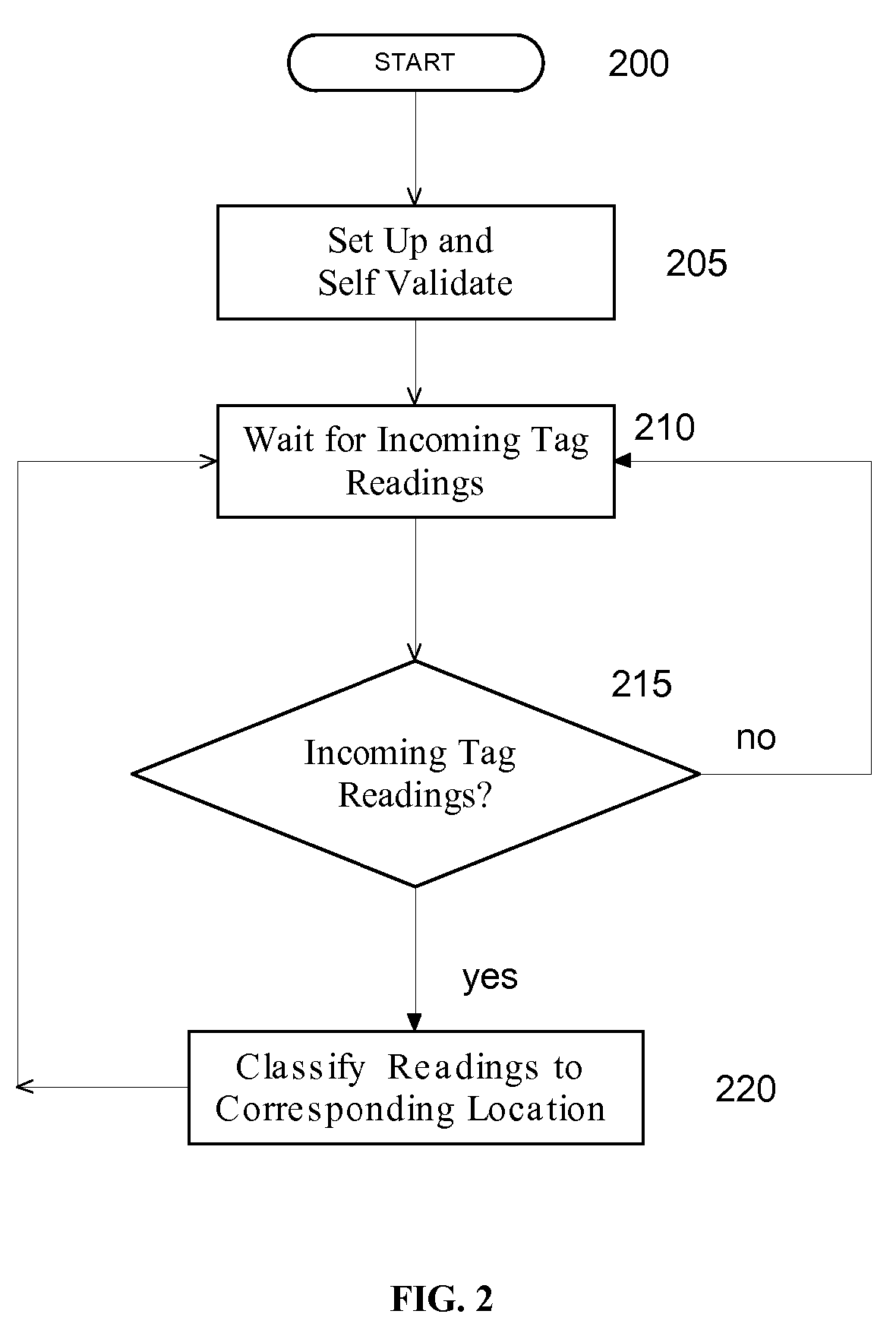

Robust RFID-Based System and Method for Precise In-House Positioning

InactiveUS20070109125A1Improve picking accuracyImprove space utilizationPosition fixationElectric/electromagnetic visible signallingClassification methodsRadio-frequency identification

A robust system, apparatus, and method for precise in-house positioning utilizing RFID (Radio Frequency Identification) technology are described in this invention. The in-house environment is partitioned into separate locations, and a set of RFID tags are scattered in the environment. Reading patterns of RFID tags are collected at each location by an RFID reader as samples. Pattern recognition and classification methods are used, when human, vehicle, or other carrier move around the environment with an RFID reader to estimate its physical location based on the reading pattern. The precision can be within one meter. The method is adaptive to different tag distribution, reader range, defective tags, and other physical constraints.

Owner:THE HONG KONG UNIV OF SCI & TECH

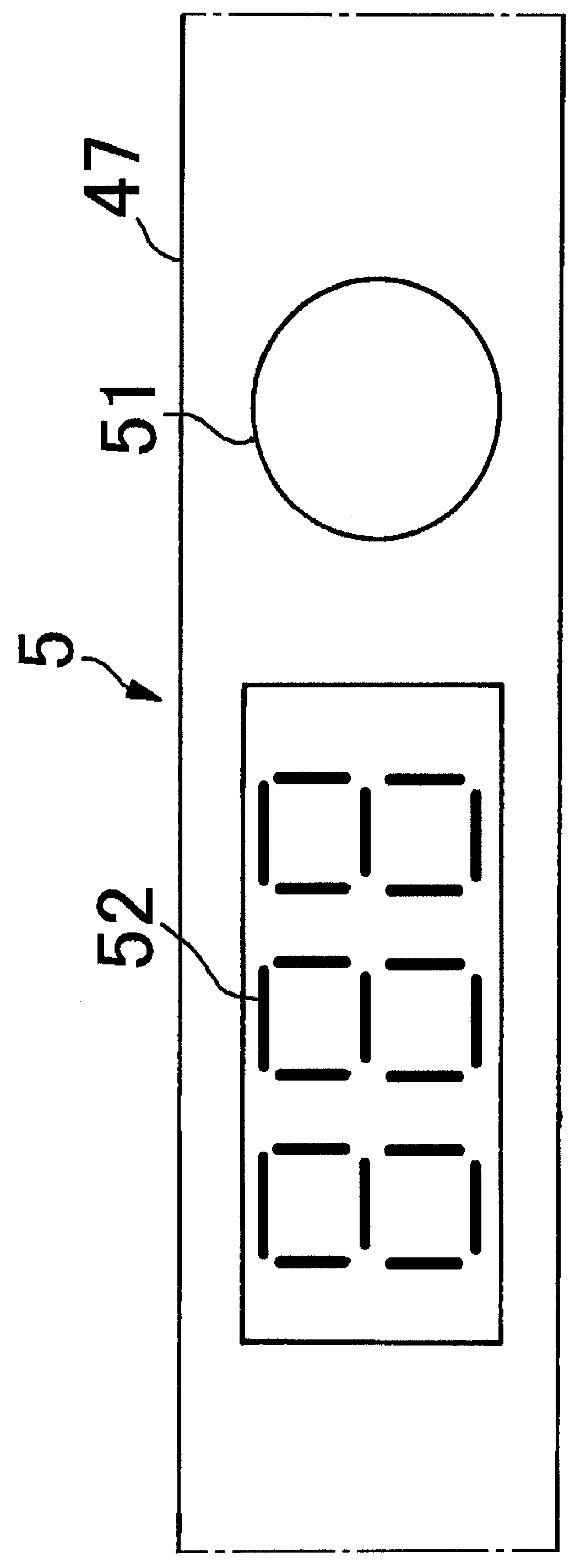

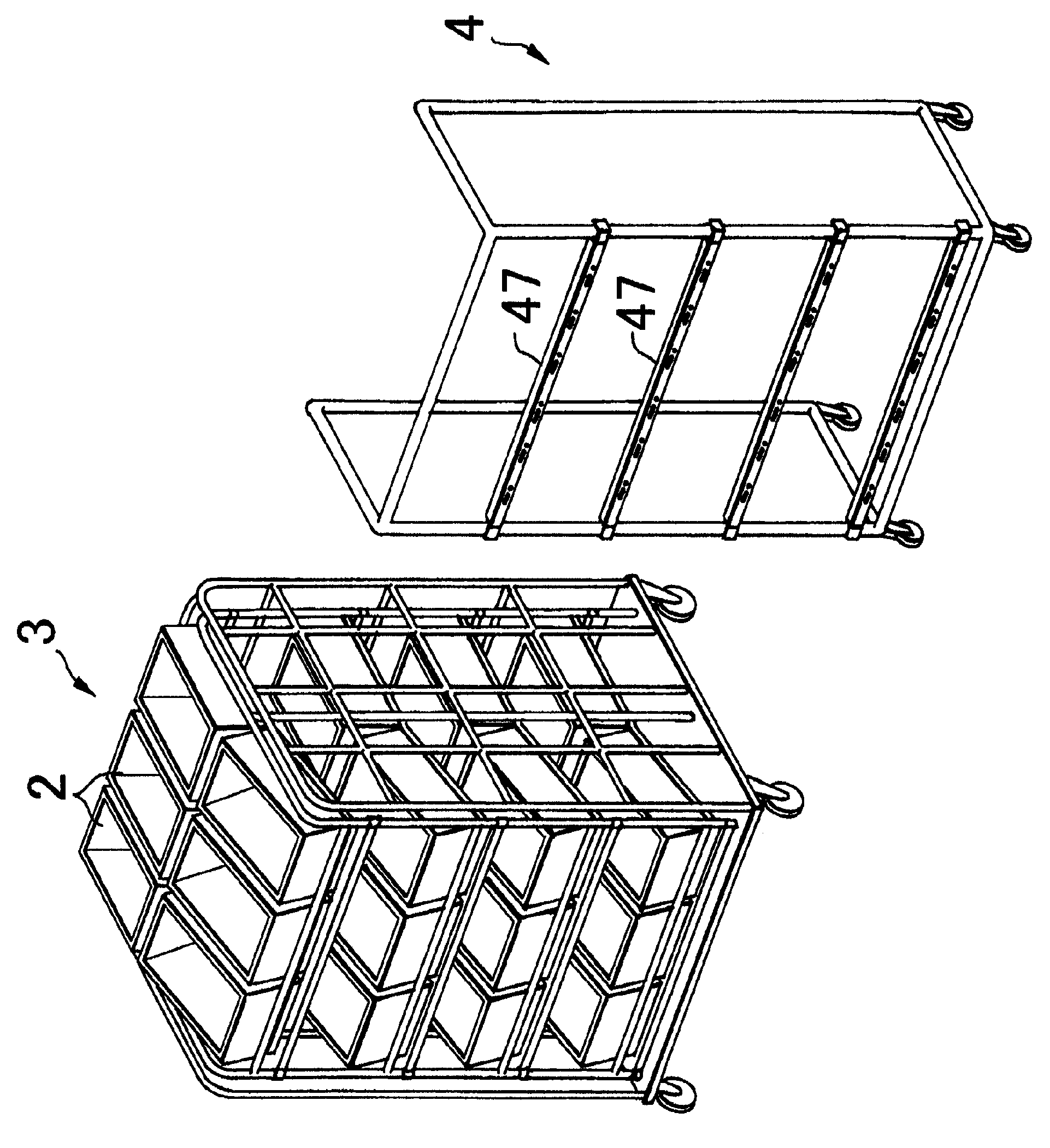

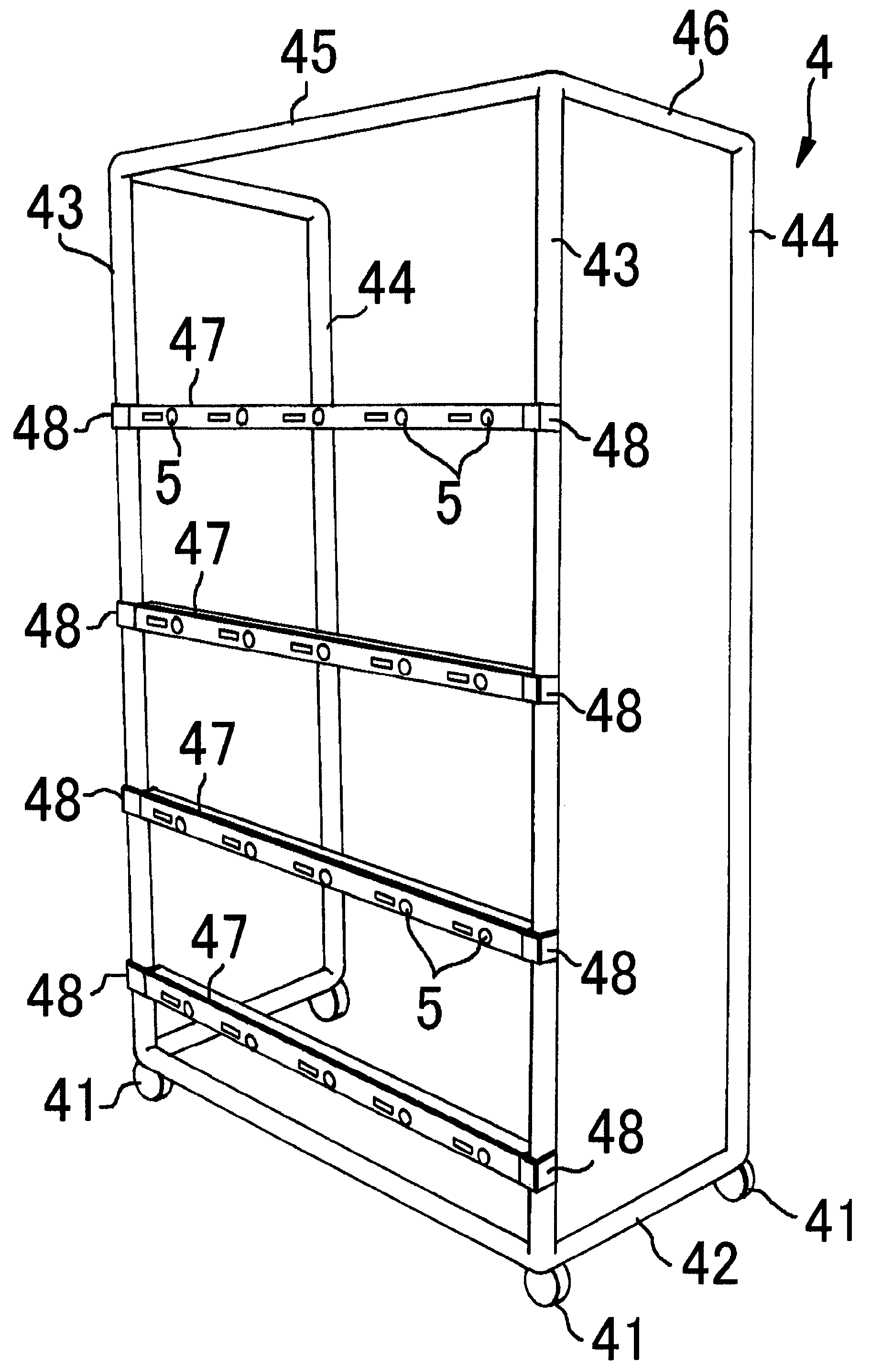

Picking system, picking gate, and article sorting method

ActiveCN103261057APick right and fastShorten delivery timePackagingStorage devicesInformation processingDisplay device

In order to flexibly configure a picking facility so that a desired article can be correctly picked in a short time from the storage location thereof, a picking system is configured from: containers (2) which each have an open top surface and house an article, a rack (3) on casters which has an open front surface and is formed by installing shelf plates (31), on which the containers (2) are mounted, vertically in multiple tiers; a picking gate (4, 4A) which is formed by hanging horizontal crosspieces (47) each equipped with indicators (5) of picking information vertically in multiple tiers between vertical crosspieces (43); and a picking information processing device (6) which is provided with a management computer (61), a controller (62) that controls the operations of the indicators (5), a handy terminal (64) and an inspection processing terminal (66) that transmit and receive information to and from the management computer (61), and which processes picking information.

Owner:YAMATO HOLDINGS

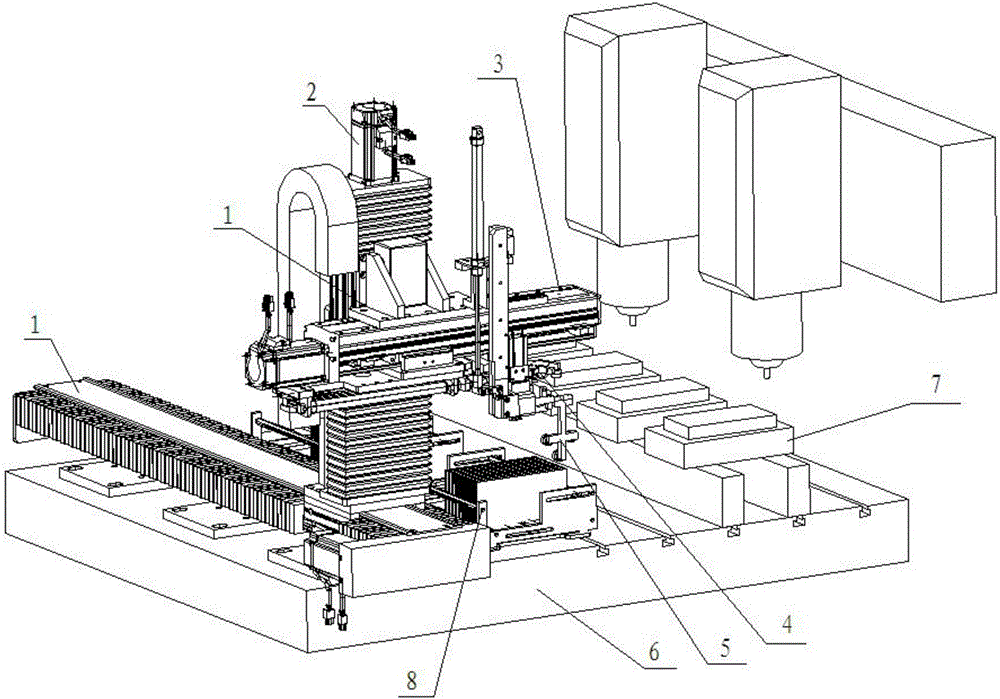

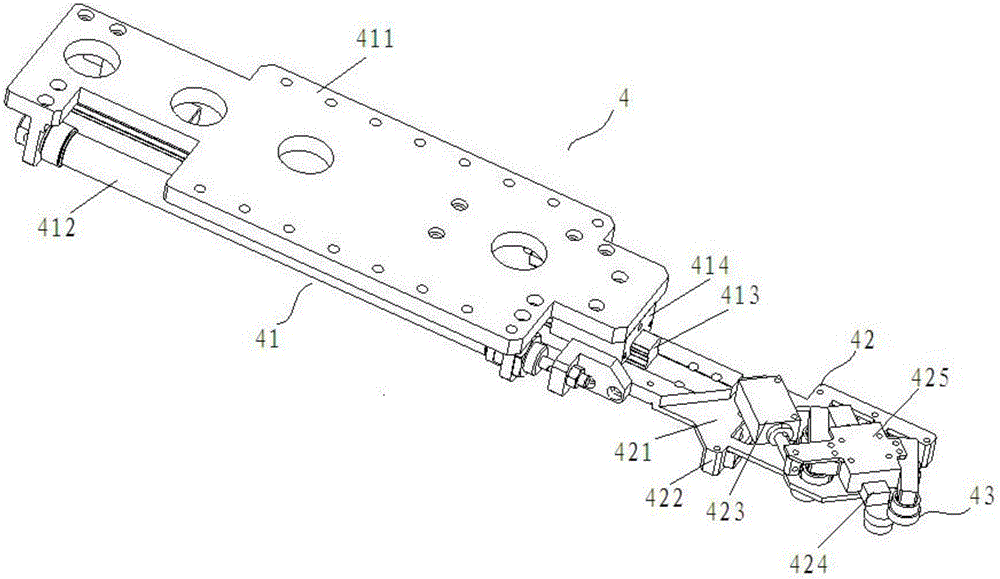

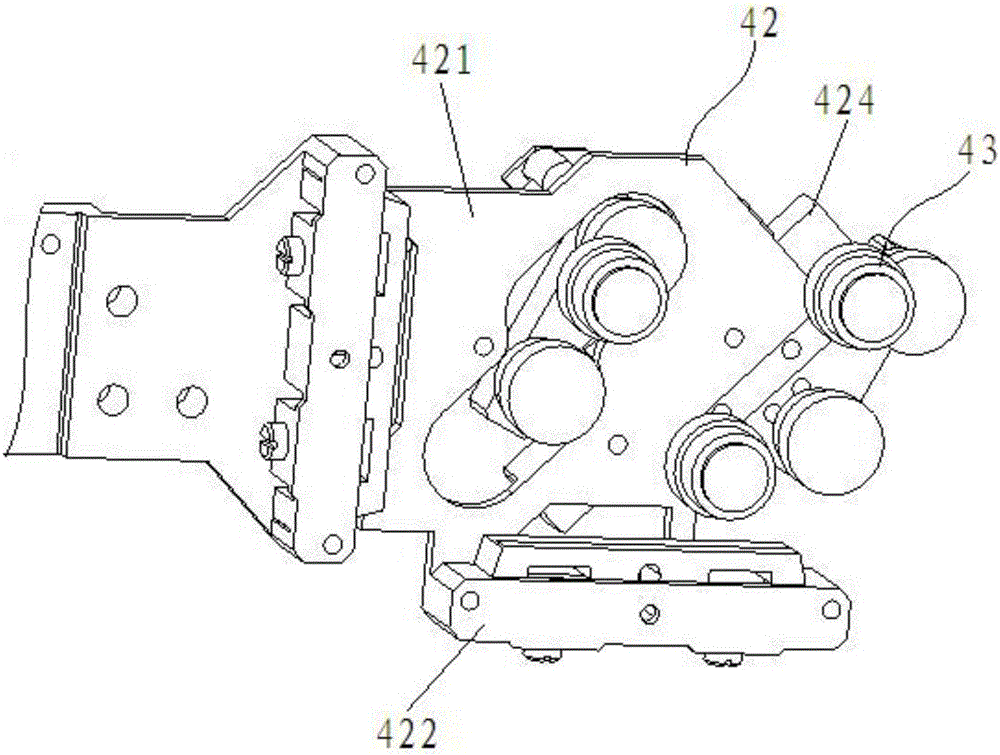

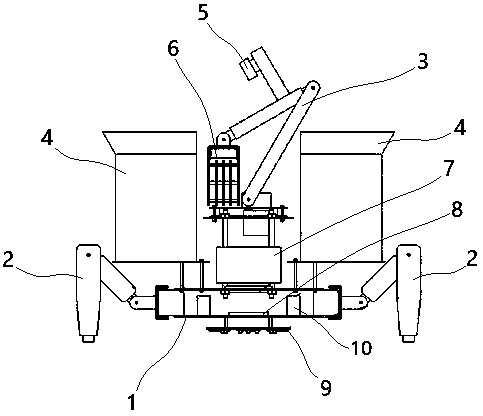

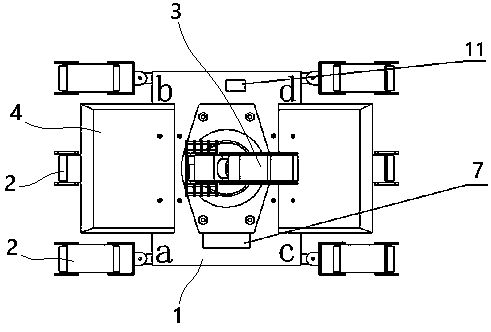

Material loading and unloading device

ActiveCN106004192AReduce movementImprove picking accuracyOther artistic work equipmentsConveyor partsEngineeringManipulator

The invention discloses a material loading and unloading device. The material loading and unloading device comprises an X axis moving mechanism, a Y axis moving mechanism and a Z axis moving mechanism. The material loading and unloading device further comprises a first picking mechanism and a second picking mechanism. The first picking mechanism comprises a first manipulator; the first manipulator is installed on the Y axis moving mechanism; the first manipulator is driven to move along the Y axis direction by the Y axis moving mechanism and driven to load materials onto machining tables and unload the materials from the machining tables by the X axis moving mechanism, the Y axis moving mechanism and the Z axis moving mechanism. The second picking mechanism comprises a Z axis auxiliary moving assembly, a rotating assembly and a second manipulator; the Z axis auxiliary moving assembly is installed on the Z axis moving mechanism, the rotating assembly is installed on the Z axis auxiliary moving assembly, and the second manipulator is installed on the rotating assembly; the rotating assembly and the second manipulator are driven to move along the Z axis direction by the Z axis auxiliary moving assembly, and the second manipulator is driven to rotate by the rotating assembly; the second manipulator is driven to load the materials onto the first manipulator and unload the materials from the first manipulator by the Z axis auxiliary moving assembly and the rotating assembly. The device is small in overall structure and higher in picking accuracy.

Owner:DONGGUAN RBD TECH

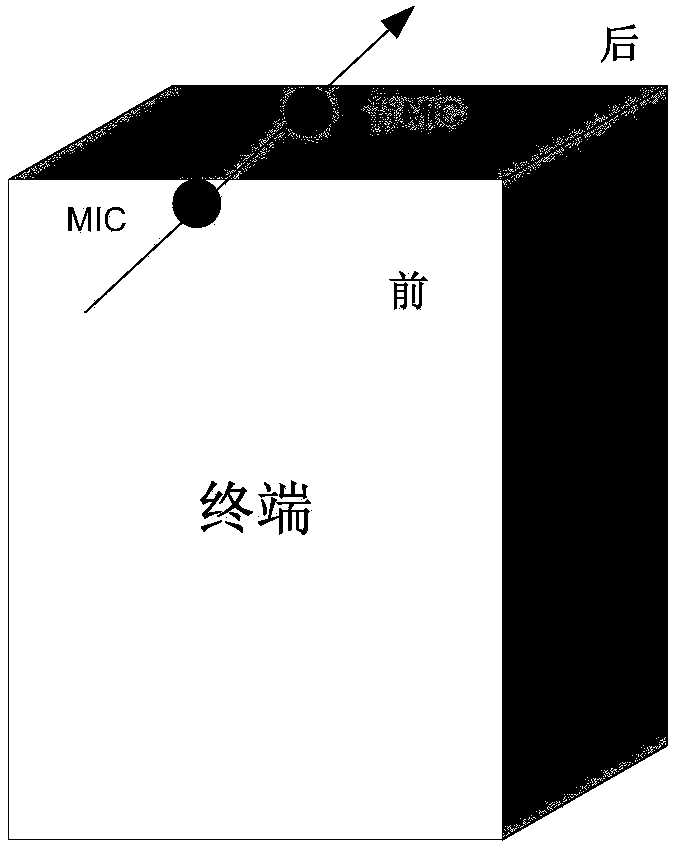

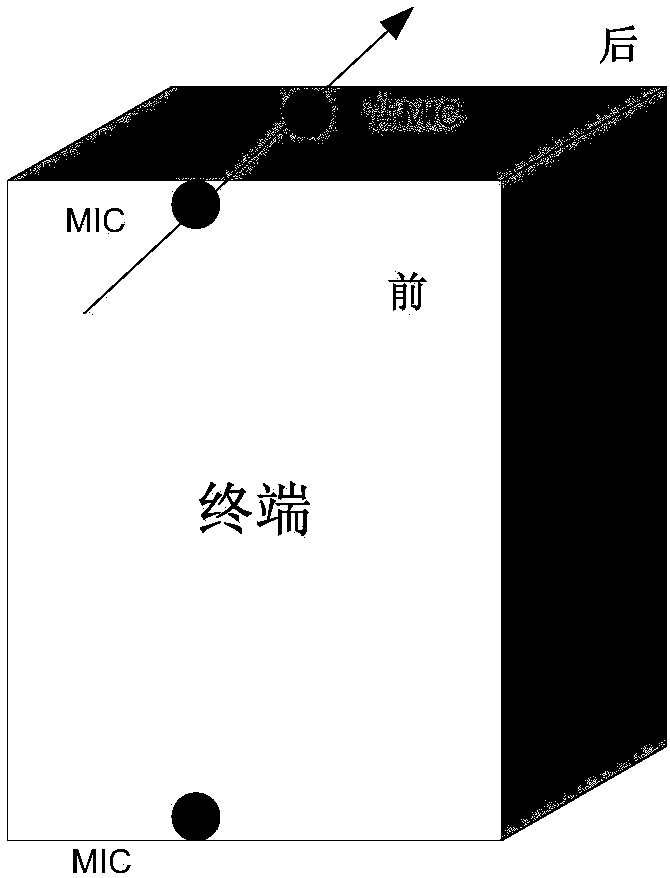

Voice processing method and device

ActiveCN109036448AGuaranteed sound qualityImprove experienceSpeech analysisPosition fixationSound sourcesSignal-to-noise ratio (imaging)

The invention discloses a voice processing method and device. The method is applied to a terminal having two microphones on the top, the two microphones are located on the front and the back of the terminal respectively, and the method is applied to a non-video call scene. The method comprises acquiring a voice signal by using the two microphones when it is detected that the camera of the terminalis in a capture state; calculating a sound pressure difference between the two microphones according to a first predetermined algorithm based on the acquired voice signal; determining whether the sound pressure difference satisfies a sound source direction determination condition; if so, determining whether a backward voice signal is included in the voice signal according to the sound pressure difference, wherein the backward voice signal is a voice signal whose sound source is located behind the camera; if it is determined that the voice signal includes the backward voice signal, filtering out the backward voice signal in the voice signal. In this way, the method locates the sound source based on the sound pressure difference in a low SNR scene and can improve the pickup accuracy of thesound source within an imaging range.

Owner:HUAWEI TECH CO LTD

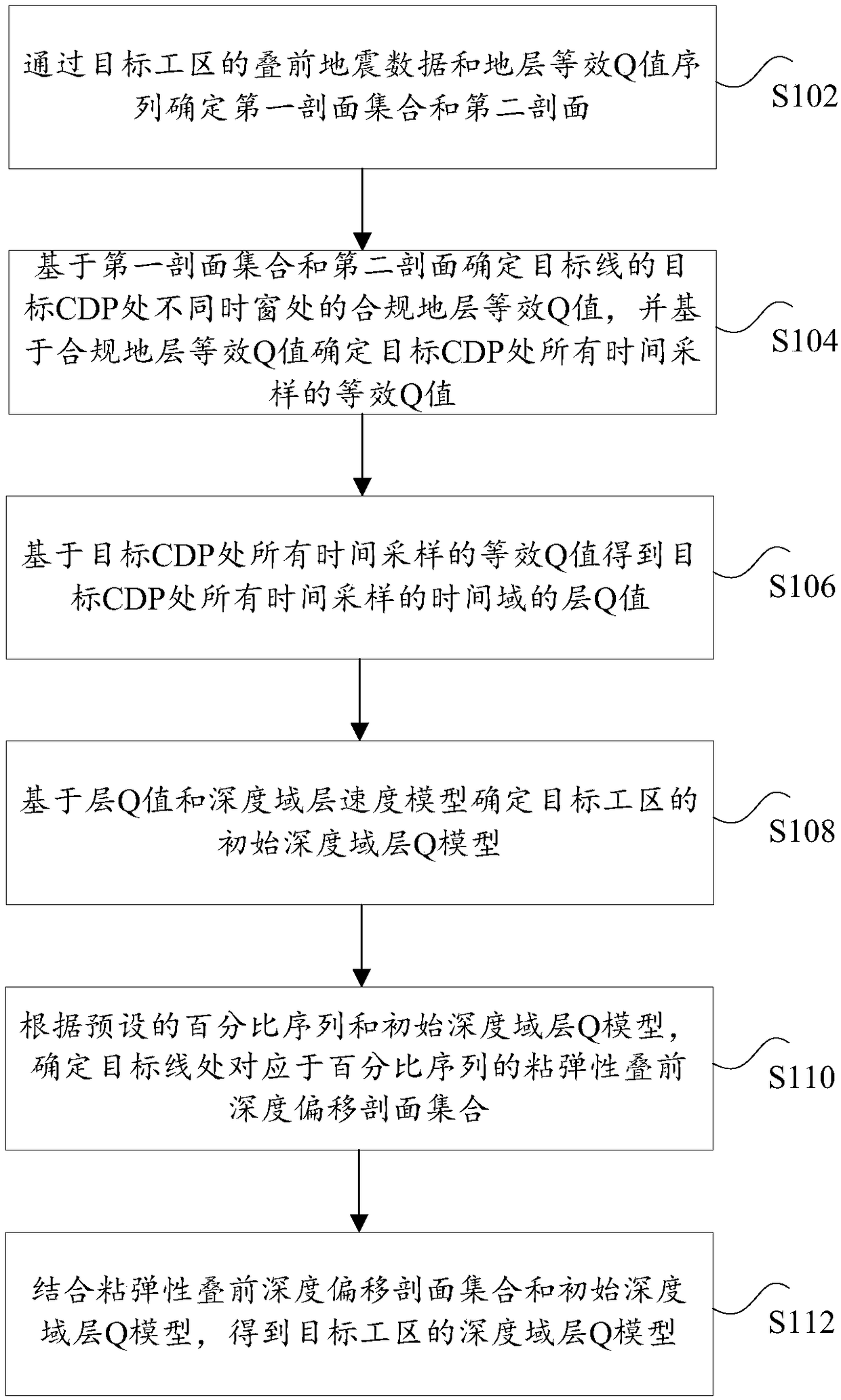

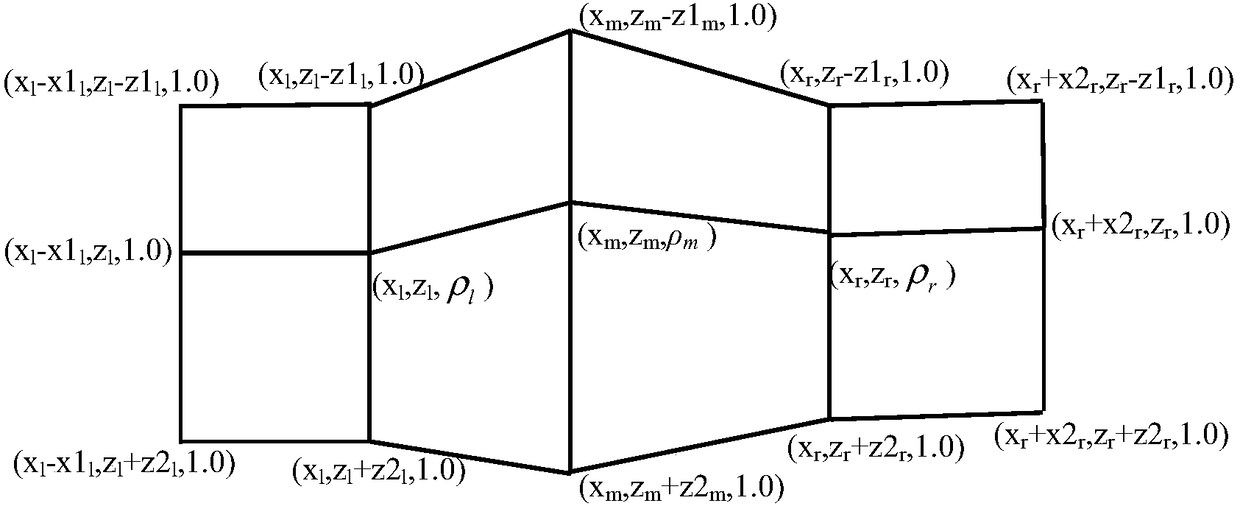

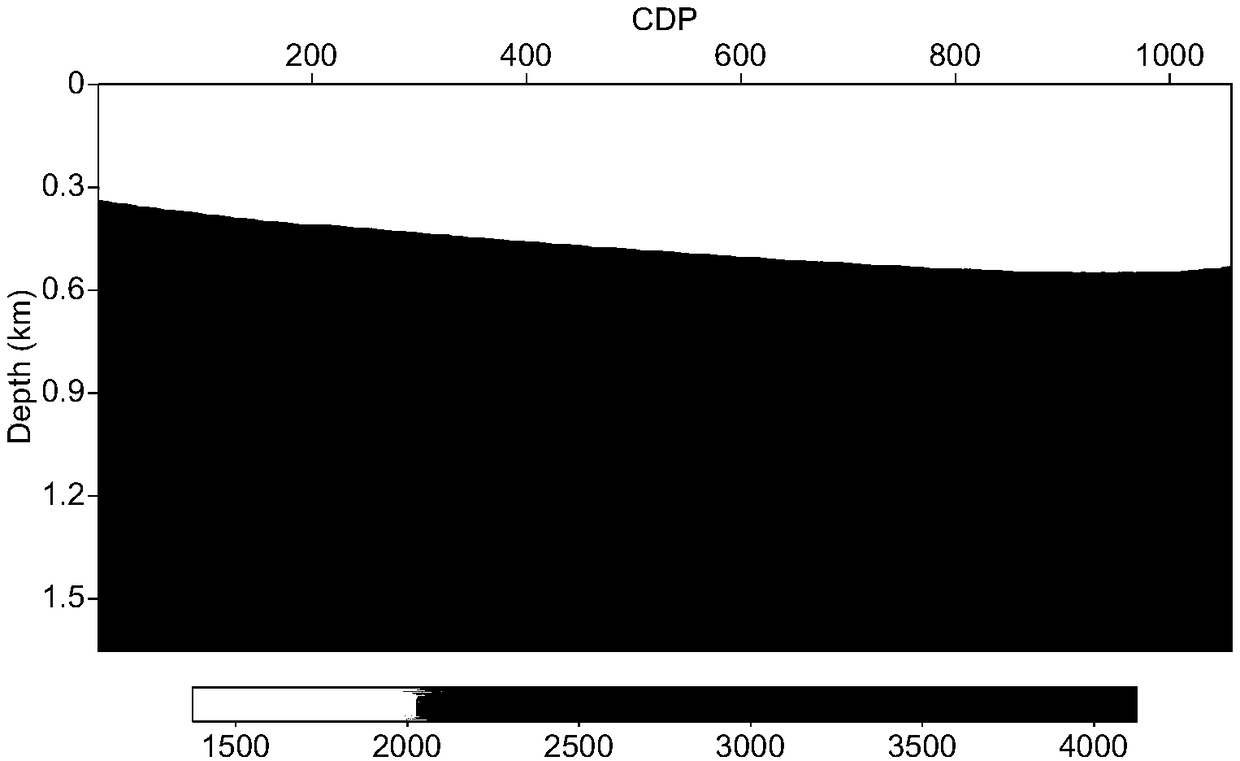

Method and system for establishing depth domain layer Q model based on reflection seismic data

ActiveCN108445538AImprove resolutionOvercoming the key hurdle of parametric field modelingSeismic signal processingTime domainTarget line

The invention provides a method and system for establishing a depth domain layer Q model based on reflection seismic data. The method is characterized by determining a first profile set and a second profile according to pre-stack seismic data of a target work area and a stratum equivalent Q value sequence; based on the first profile set and the second profile, determining a compliance stratum equivalent Q value of a target line at a target CDP in different time windows, and determining an equivalent Q value of all time sampling at the target CDP based on the compliance stratum equivalent Q value; obtaining a layer Q value of a time domain at the target CDP based on the equivalent Q value of all time sampling at the target CDP; determining an initial depth domain layer Q model of the targetwork area based on the layer Q value and depth domain interval velocity; according to a preset percentage sequence and the initial depth domain layer Q model, determining a viscoelasticity pre-stackdepth migration profile set corresponding to the percentage sequence; and based on the viscoelasticity pre-stack depth migration profile set and the initial depth domain layer Q model, obtaining the depth domain layer Q model of the target work area.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

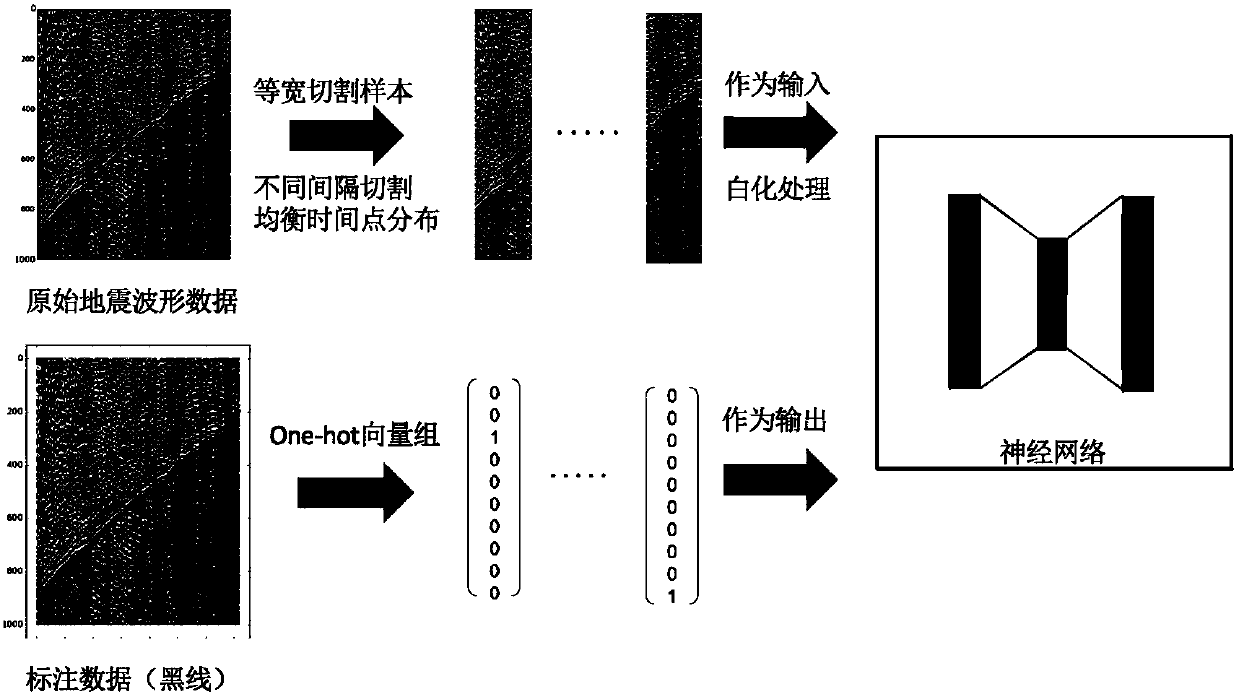

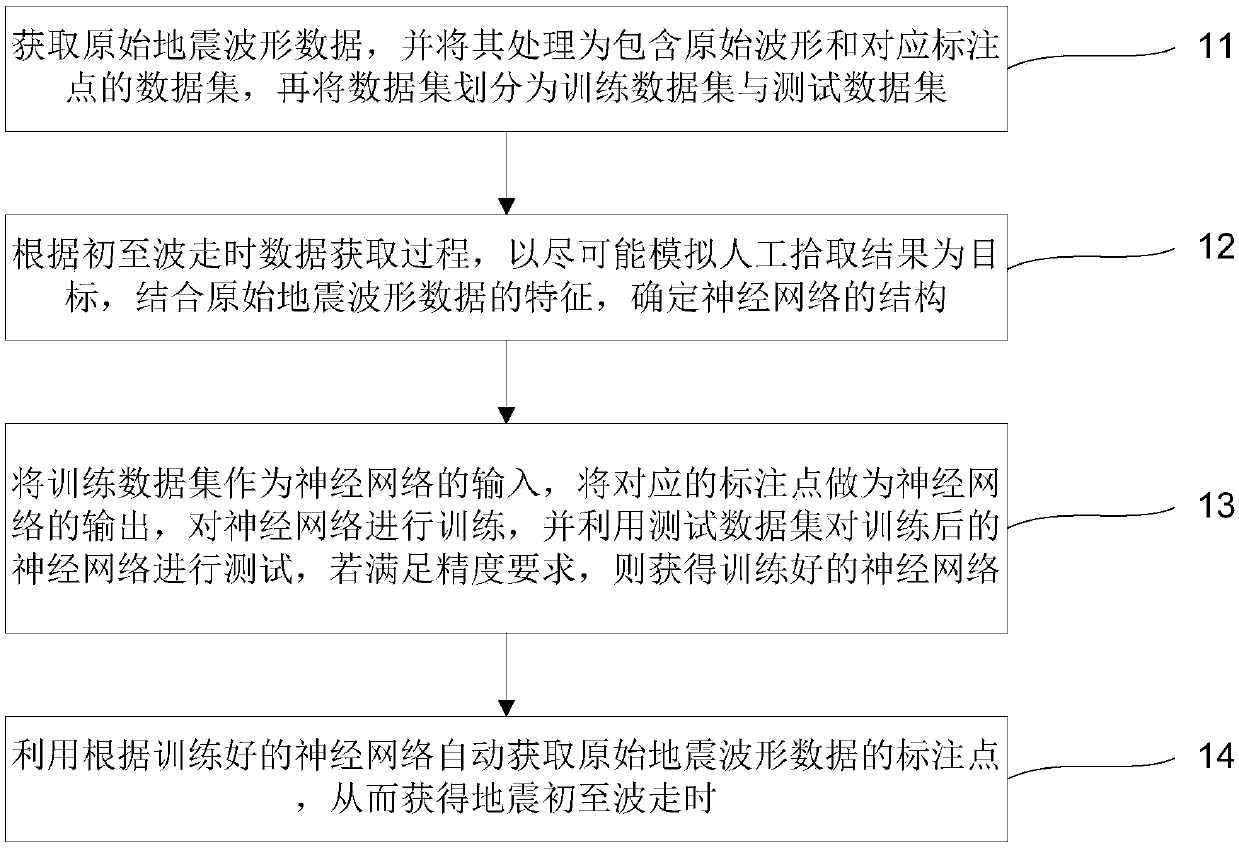

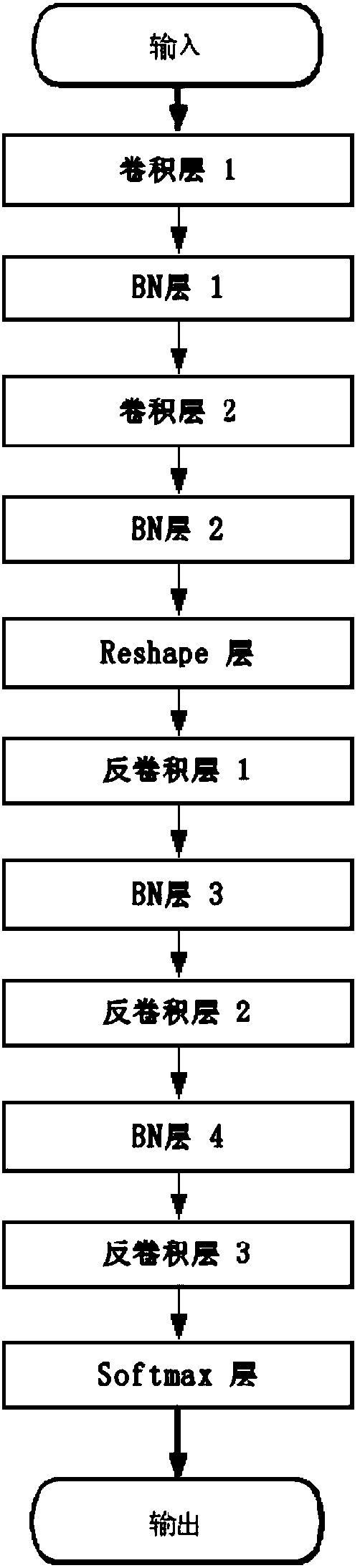

Neural-network-based acquisition method of seismic first arrival wave travel time

The invention discloses a neural-network-based acquisition method of seismic first arrival wave travel time. The method comprises: original seismic waveform data are obtained, the obtained data are processed into a data set including an original waveform and a corresponding marking point, and the data set is divided into a training data set and a testing data set; according to a first arrival wavetravel time data obtaining process, a structure of a neural network is determined by taking simulation of a manual pick-up result as a target and combining features of the original seismic waveform data; the neural network is trained by using the training data set as an input of the neural network and the corresponding marking point as an output of the neural network, the trained neural network is tested by using the testing data set, and if a precision requirement is met, a trained neural network is obtained; and the marking point of the original seismic waveform data is obtained automatically based on the trained neural network and thus seismic first arrival wave travel time is obtained. Therefore, the accuracy of automatic acquisition of the seismic first arrival wave travel time is improved and the manual correction workload is reduced.

Owner:UNIV OF SCI & TECH OF CHINA

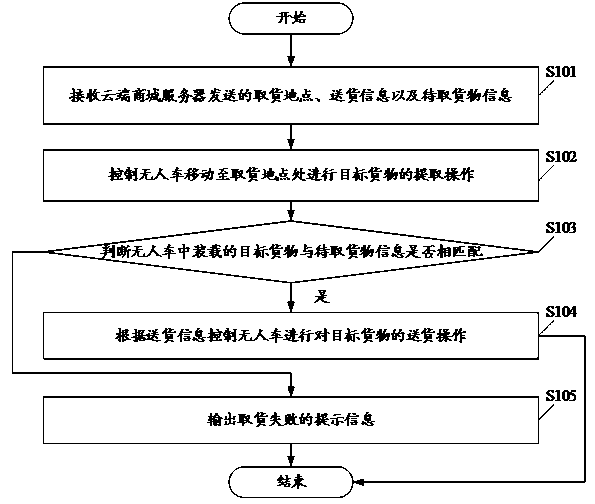

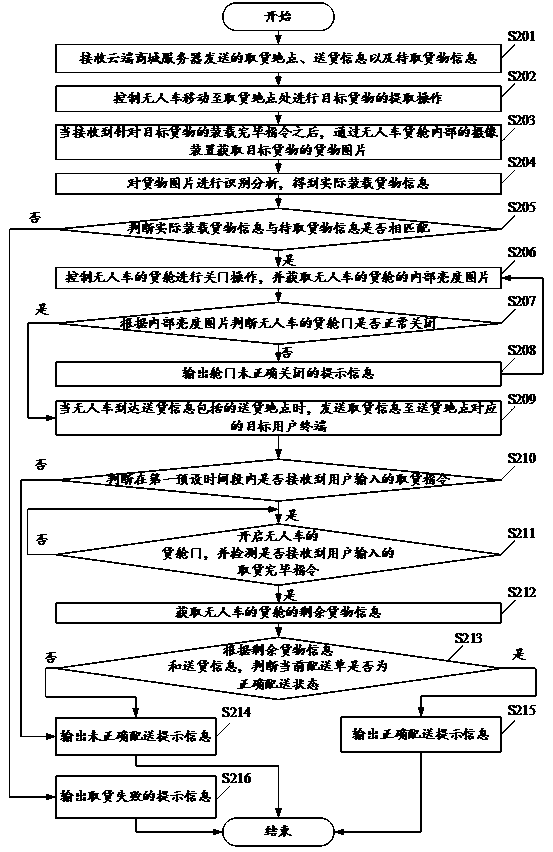

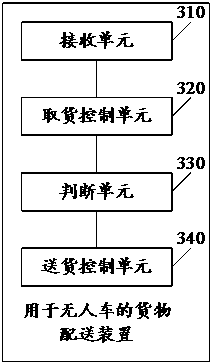

Cargo distribution method, device and system for unmanned vehicle

InactiveCN111401823AImprove picking accuracyImprove distribution efficiencyBuying/selling/leasing transactionsLogisticsInformation controlDistribution method

The invention provides a cargo distribution method, device and system for an unmanned vehicle, and relates to the technical field of unmanned vehicle control. The cargo distribution method for the unmanned vehicle comprises the steps: after receiving a goods taking place, goods delivery information and to-be-taken goods information sent by a cloud shopping mall server, enabling the unmanned vehicle to firstly move to the goods taking place to carry out target goods extraction operation; after the target is obtained and extracted, automatically judging whether the target goods loaded in the unmanned vehicle are matched with the to-be-taken goods information or not, so as to determine whether goods taking succeeds or not; and controlling the unmanned vehicle to carry out delivery operation on the target goods according to the delivery information when the matching is judged. Whether the goods are correctly loaded or not is quickly and automatically checked during goods taking, so the goods taking correctness is improved, the problems of secondary goods taking and the like caused by goods taking errors are avoided, and the distribution efficiency is improved.

Owner:北京云迹科技股份有限公司

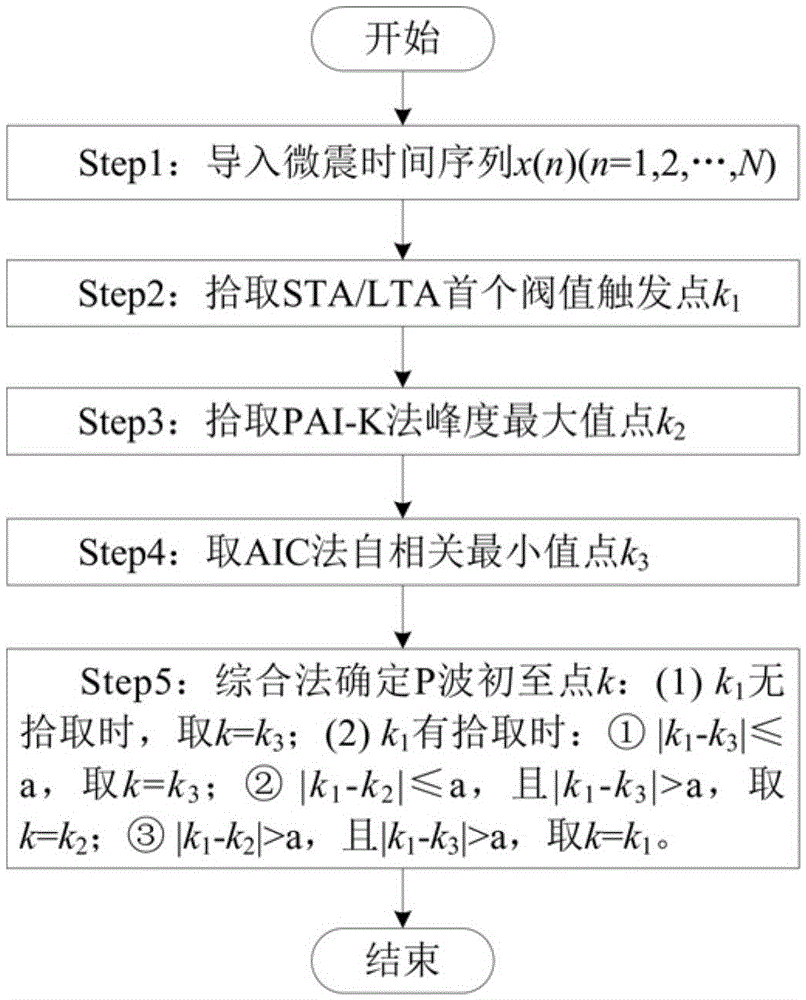

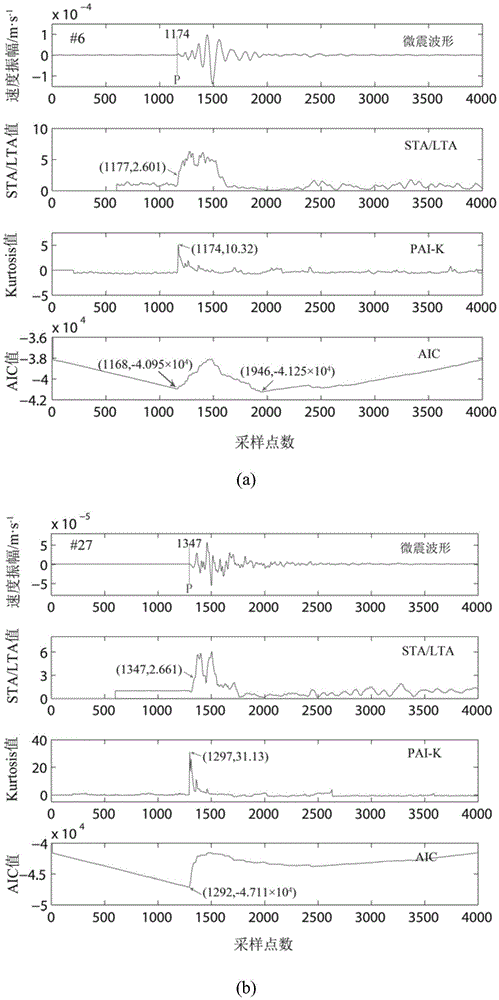

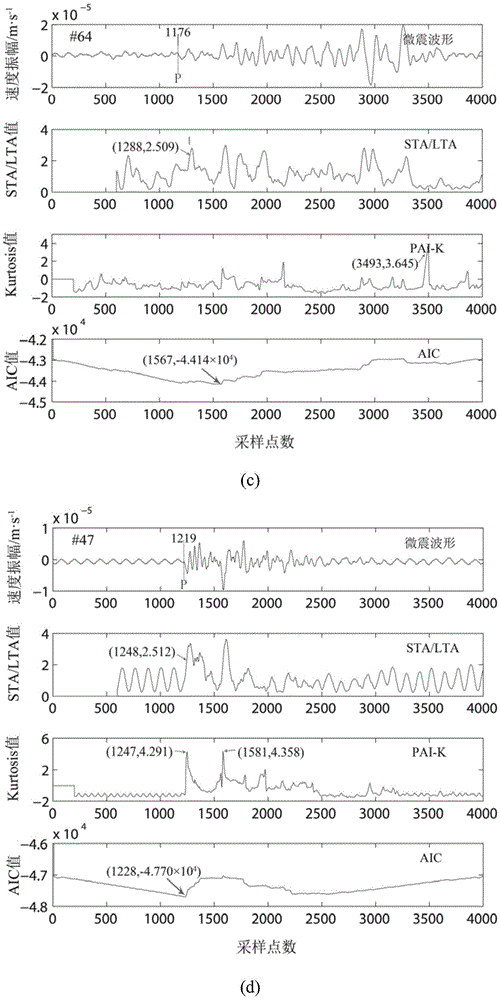

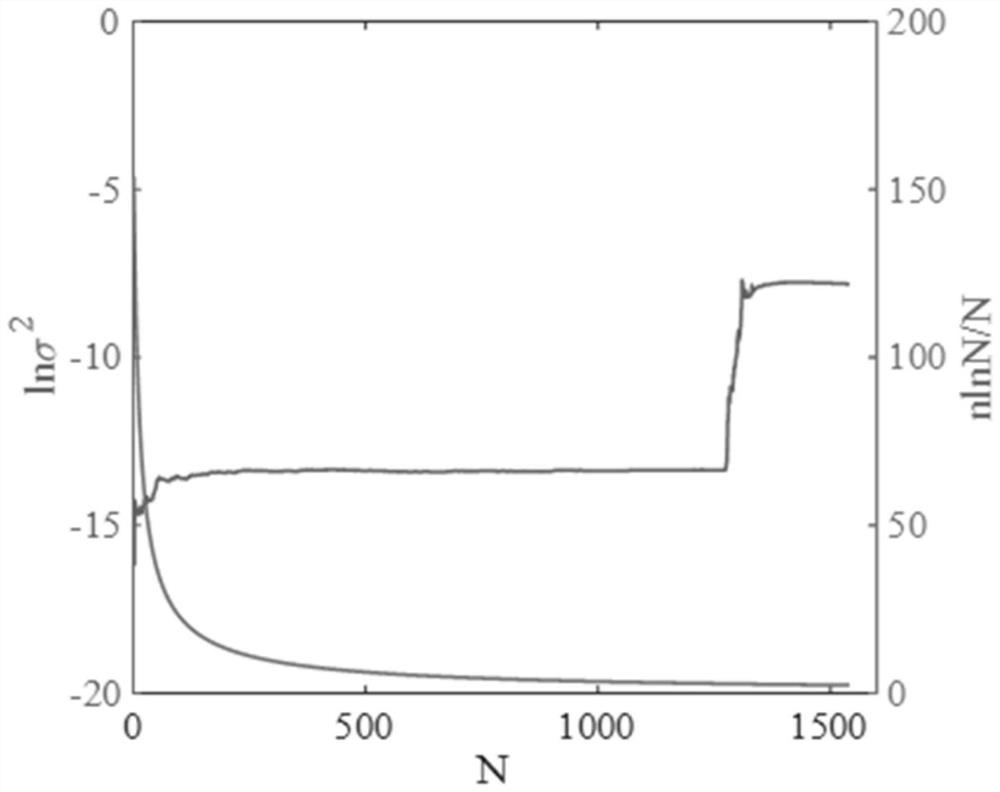

Microseismic signal P-wave first arrival point comprehensive pickup method

ActiveCN105487114ASolve the problem of poor picking stabilityImprove picking accuracySeismic signal processingSelf correlationComputer science

The invention discloses a microseismic signal P-wave first arrival point comprehensive pickup method, which comprises the following steps: inputting microseismic time series data; picking up a first threshold value trigger point k1 through an STA / LTA method; picking up a kurtosis maximum point k2 through a PAI-K method; picking up a self-correlation minimum value point k3 through an AIC method; and determining a P-wave first arrival point k through a comprehensive method: (1) when the k1 has no pickup, k=k3, and (2)when the k1 has pickup:1) if |k1-k3|<=a, k=k3, 2) if |k1-k2|<=a, and |k1-k3|>a, k=k2, and 3) if |k1-k2|>a and |k1-k3|>a, k=k1. The comprehensive pickup method effectively solves the technical problems that the number of no-pickup events is large and pickup precision is low in the STA / LTA method and that the pickup stability of the PAI-K method and the AIC method is poor. The method has the advantages of easy processing, high applicability and high accuracy and the like.

Owner:CENT SOUTH UNIV

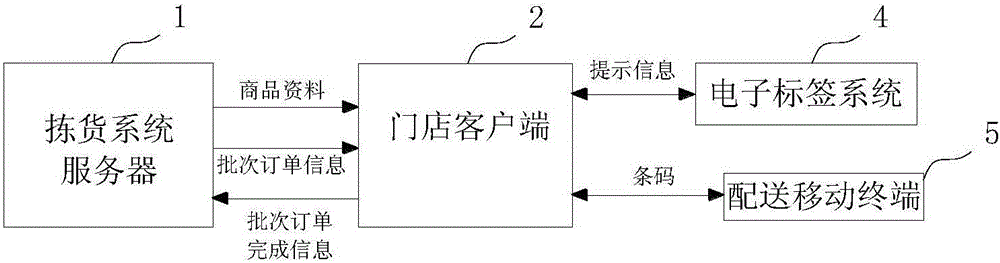

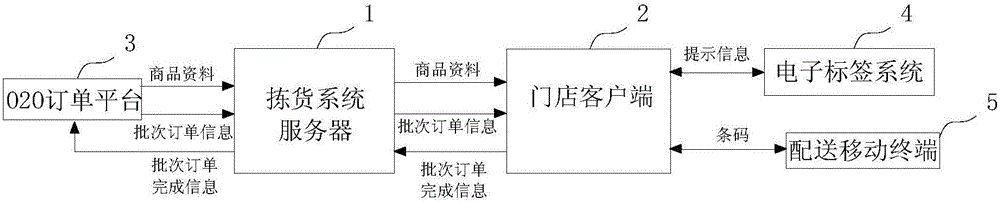

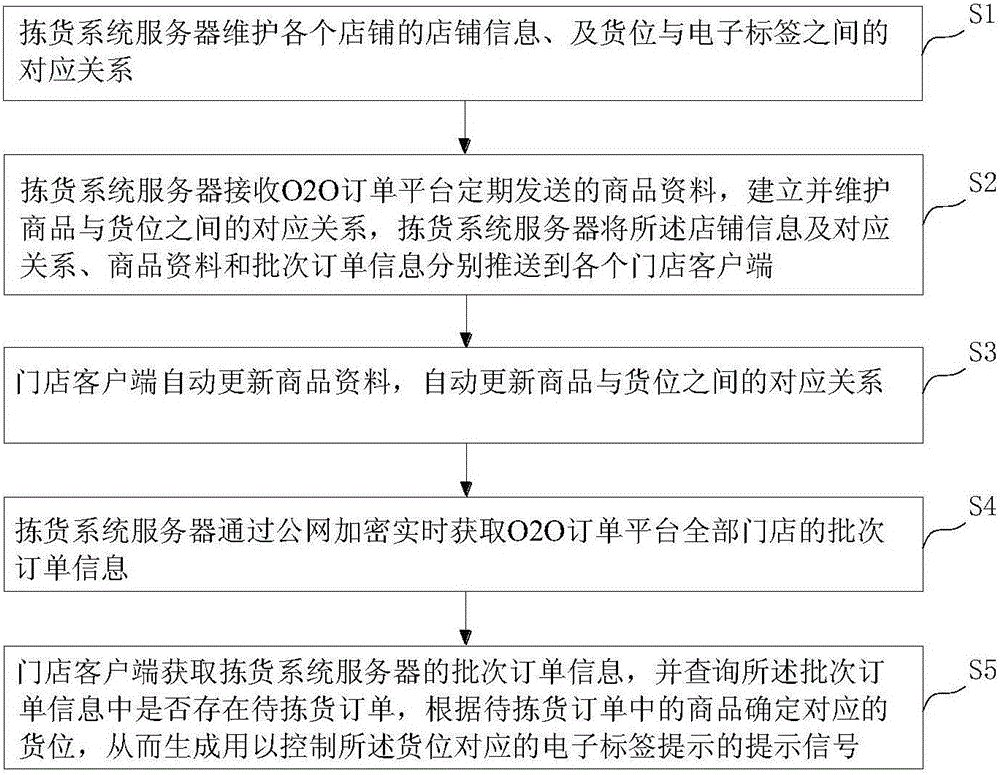

Order picking system applied to catering O2O (online to offline) mode and method

The invention provides an order picking system applied to a catering O2O (online to offline) mode and an order picking method applied to the catering O2O (online to offline) mode. The system includes a picking system server and at least one store client; the picking system server is used for maintaining store information, maintaining corresponding relationships between commodities of each store and commodity locations, maintaining corresponding relationships between the commodity locations and electronic labels, obtaining commodity information and batch order information from an O2O order platform, and pushing the above information to each store client; and the at least one store client is used for obtaining the above information from the picking system server, querying whether orders to be picked exists in the batch order information and determining corresponding commodity locations according to commodities in the orders to be picked so as to generate prompting signals used for controlling electronic label prompts corresponding to the commodity locations. With the order picking system and method of the invention adopted, order picking efficiency can be improved, operation personnel can be decreased, and labor cost can be saved. The order picking system and method can be applied to factory type stores with a larger quantity of orders.

Owner:上海海鼎信息工程股份有限公司

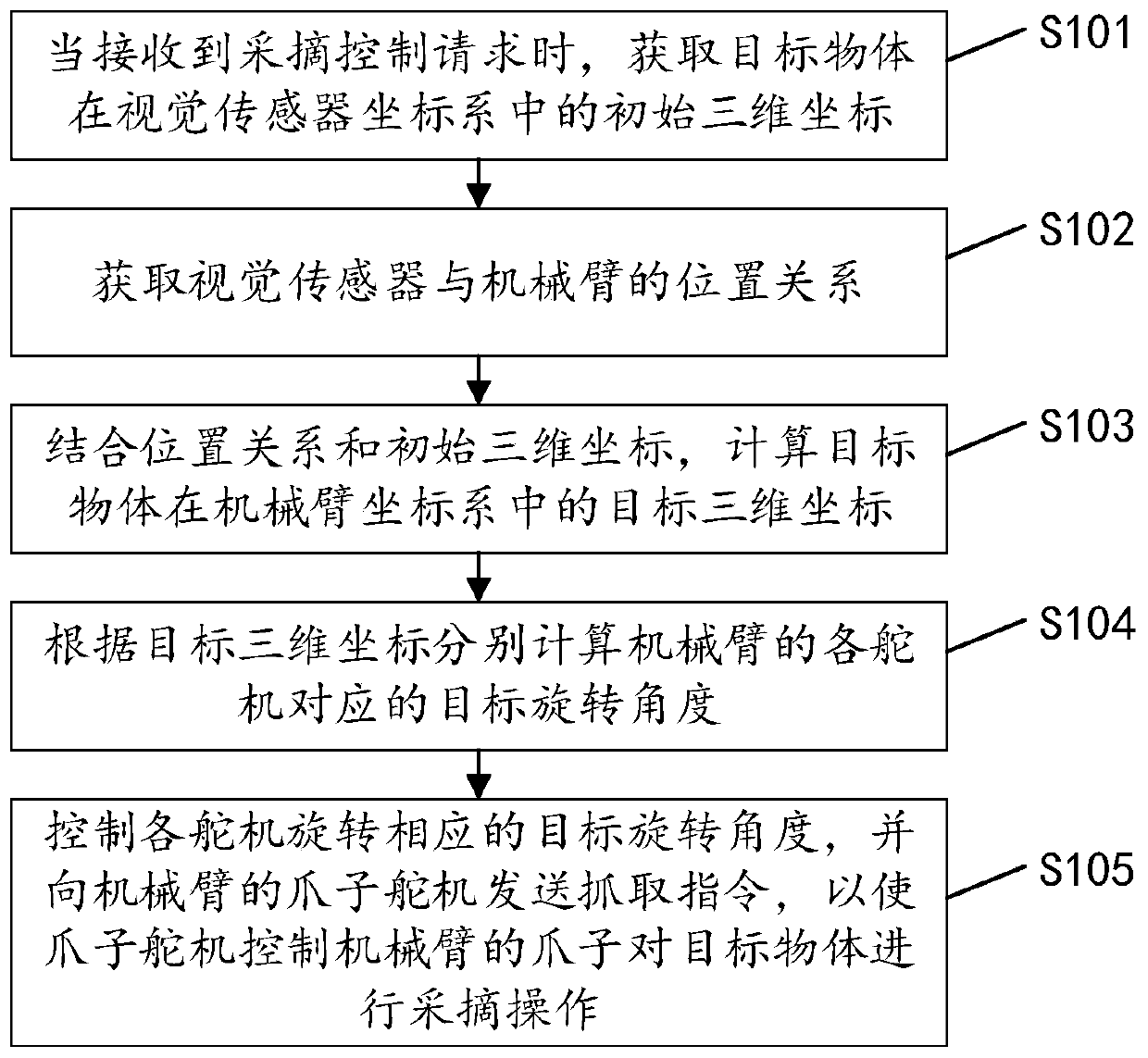

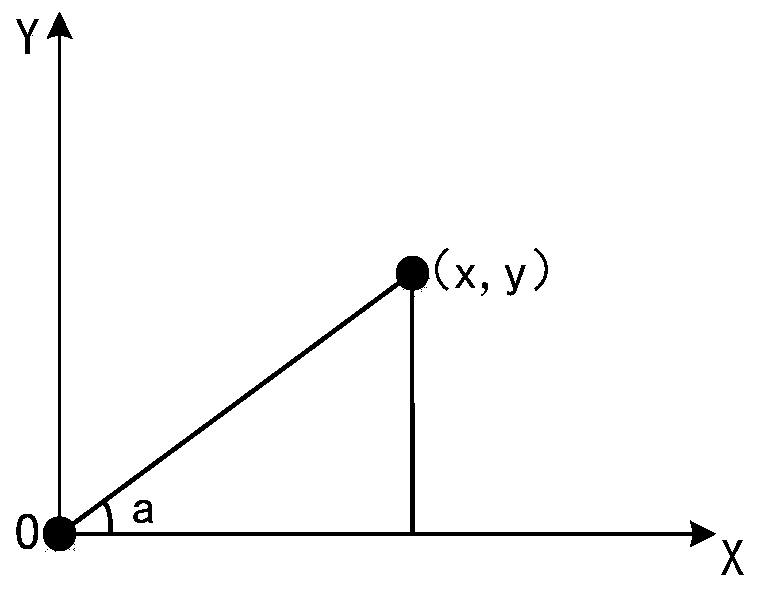

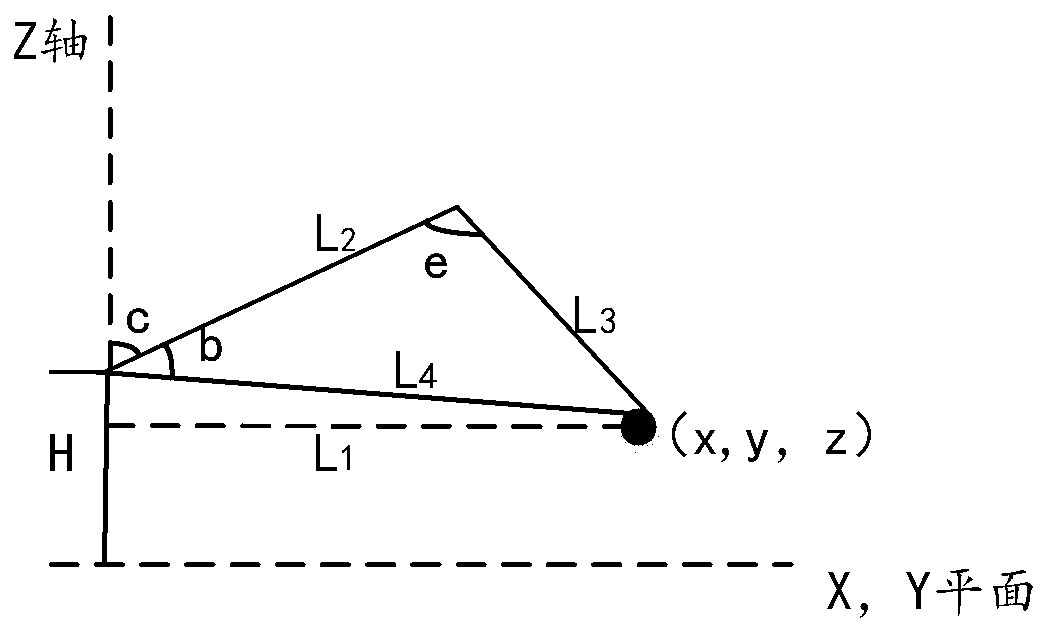

Picking control method, device and equipment and computer readable storage medium

PendingCN111360821AImprove accuracyImprove picking accuracyProgramme-controlled manipulatorPicking devicesControl engineeringControl theory

The invention discloses a picking control method, device and equipment and a storage medium. The picking control method comprises the steps of acquiring an initial three-dimensional coordinate of a target object in a visual sensor coordinate system when a picking control request is received; obtaining a position relation between a visual sensor and a mechanical arm; calculating a target three-dimensional coordinate of the target object in a mechanical arm coordinate system by combining the position relation and the initial three-dimensional coordinate; separately calculating a corresponding target rotating angle of each steering gear of the mechanism arm according to the three-dimensional coordinate of the target object; and controlling each steering gear to rotate by the corresponding target rotating angle, and sending a grasping command to a claw steering gear of the mechanical arm so that the claw steering gear can control claws of the mechanism arm to perform picking operation on the target object. According to the technical scheme of the embodiments of the picking control method, the picking control device, the picking control equipment and the storage medium, the accuracy forcontrolling the mechanism arm is improved, the accuracy for picking the target object is improved as well, and the picking efficiency is greatly improved; and the picking control method, the pickingcontrol device, the picking control equipment and the storage medium achieve the corresponding technical effects.

Owner:HAINAN UNIVERSITY

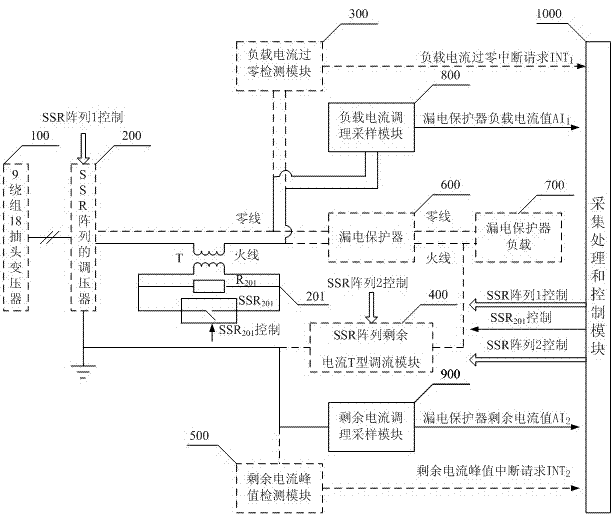

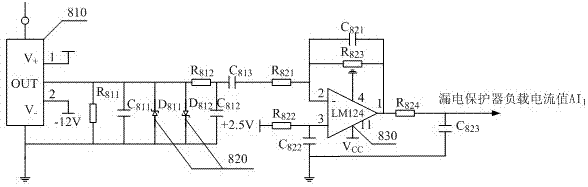

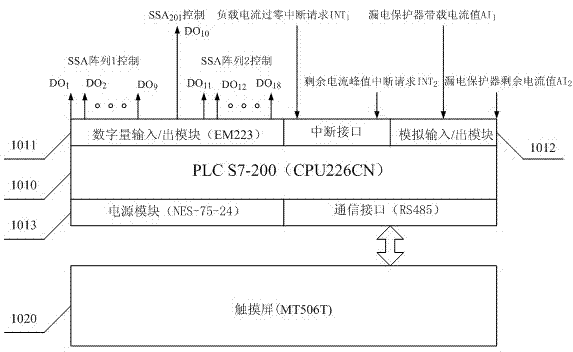

Digital detecting system for leakage protector and high-precision detecting method

InactiveCN103487699AAttenuation tap ablation degreeImprove detection accuracyElectrical testingCapacitanceTransformer

The invention discloses a digital detecting system for a leakage protector and a high-precision detecting method. The system comprises a transformer, a voltage regulator, an arc extinction circuit, a load current zero-cross detecting module, a residual current T-type regulating module, a residual current peak detecting module, the leakage protector, a leakage protector load, a load current conditioning and sampling module, a residual current conditioning and sampling module and a sampling processing and control module. According to the digital detecting system for the leakage protector and the high-precision detecting method, through the adoption of a current zero-cross voltage regulating technology of an electronic contactless type SSR and the combination of a voltage regulation and arc extinction circuit, the erosion degree of a tap by electric arcs in a voltage regulating process can be weakened effectively; digital current regulation of residual currents is achieved through a T-type network and an SSR array, and the defects that a simulation current regulating method is poor in precision and reliability and the like are overcome; detection precision is improved through a high pass capacitance and resistance detecting scheme of current peak time points; a digital framework detection system has the advantages of being high in efficiency, precision and reliability.

Owner:ZHEJIANG UNIV

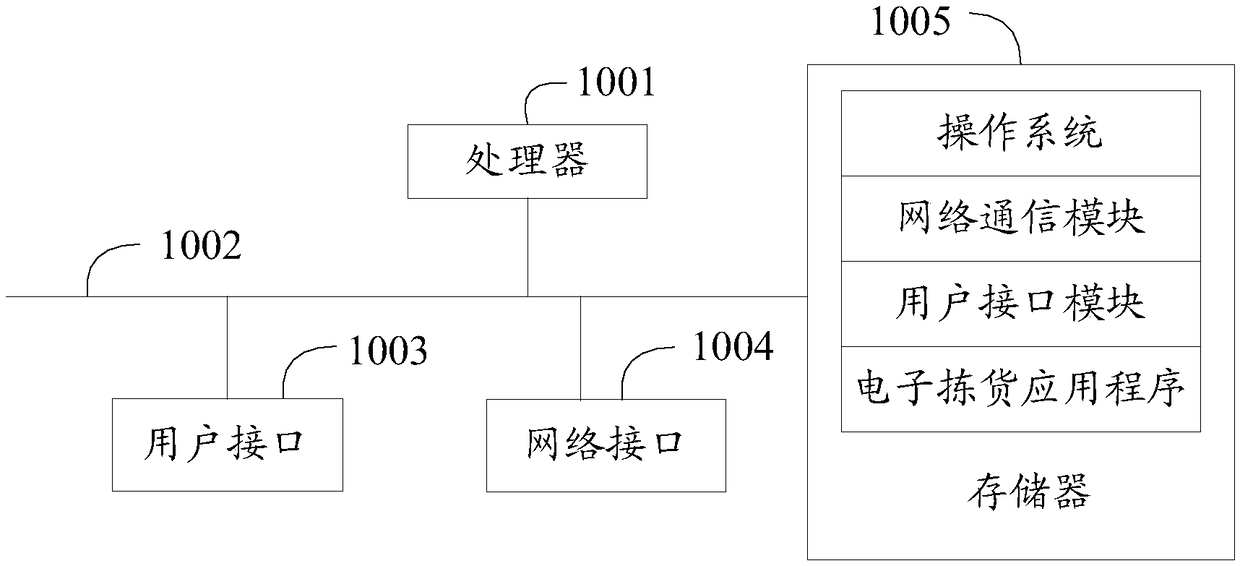

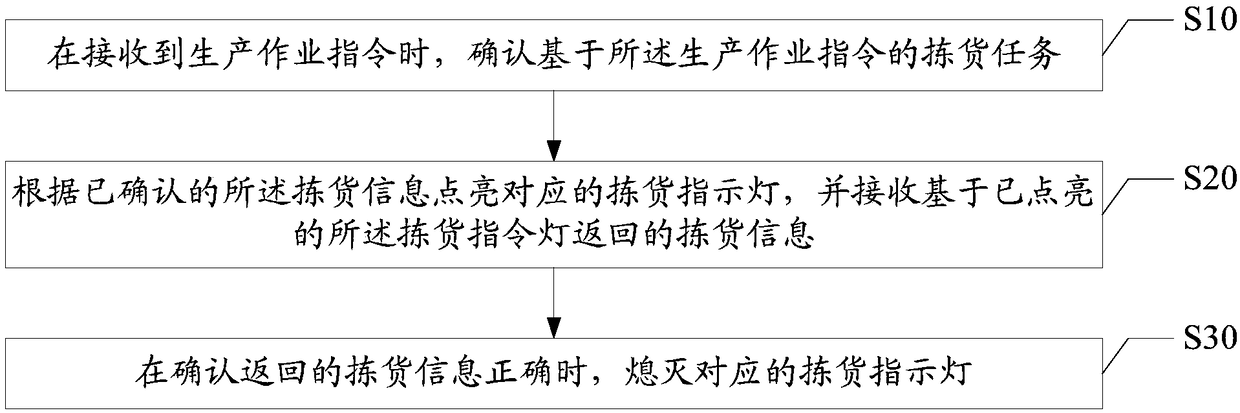

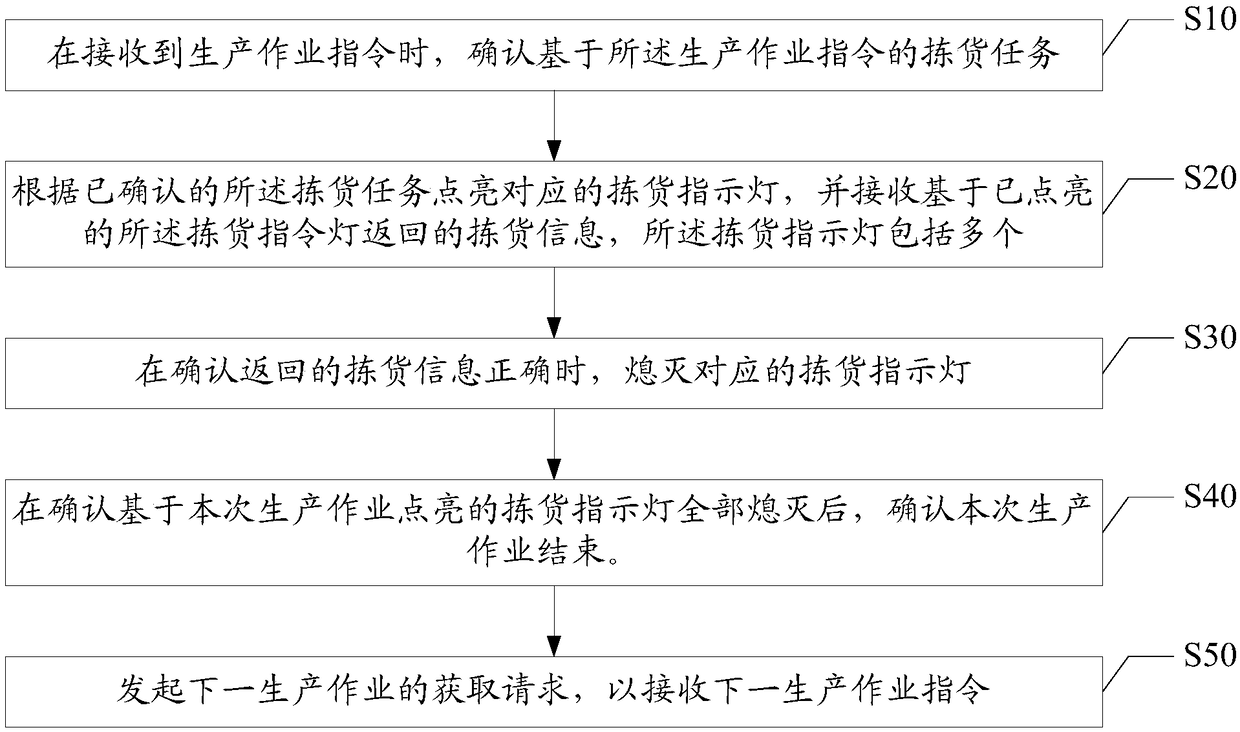

Electronic picking method and apparatus, computer readable storage medium and system

InactiveCN109359917AImprove picking accuracyLogisticsManufacturing computing systemsComputer scienceComputer engineering

The invention discloses an electronic picking method, which comprises the following steps: when receiving a production operation instruction, confirming a picking task based on the production operation instruction; lighting a corresponding picking indicator light according to the confirmed picking task, and receiving picking information returned based on the lighted picking instruction light; turning off the corresponding picking indicator when it is confirmed that the returned picking information is correct. The invention also discloses an electronic picking device, a computer-readable storage medium and a system. The invention illuminates the corresponding picking indicator light according to the picking demand, receives the picking information returned by the illuminated indicator lightand then extinguishes the picking indicator light according to the returned picking information to verify whether the picking is correct or not, and realizes the beneficial effect of improving the picking accuracy.

Owner:GAC TOYOTA MOTOR

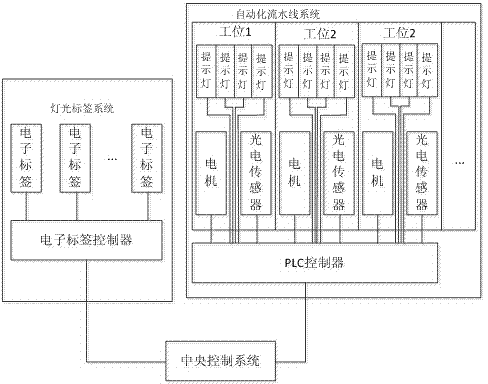

Sorting system based on grouping mode and light label and implementation method of sorting system

InactiveCN104707806ALow costIncrease flexibilitySortingStorage devicesElectronic taggingControl system

The invention discloses a sorting system based on a grouping mode and a light label and an implementation method of the sorting system. The system comprises an automatic assembly line system, a light label system mounted on the automatic assembly line system, and a central control system for simultaneously controlling the light label system and the automatic assembly line system, wherein the automatic assembly line system comprises a conveyor belt, storage racks arranged on the two sides of the conveyor belt, a PLC connected with the central control system, as well as a motor and a photoelectric sensor which are respectively connected with the PLC; the light label system comprises radio frequency identifications arranged at temporary storage positions, and a radio frequency identification controller simultaneously connected with the radio frequency identifications; the radio frequency identification controller is connected with the central control system. The sorting system disclosed by the invention adopts a semi-machine semi-manual sorting manner, can be applied to sorting multiple crops, is low in cost, high in flexibility, high in sorting accuracy, high in efficiency, low in requirement on professional skills of staff and a warehouse information-based system, and suitable for large-scale popularization and application.

Owner:CHENGDU SUNYUKI AGRI TECH

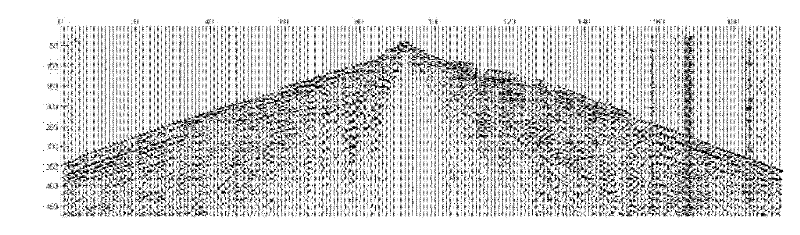

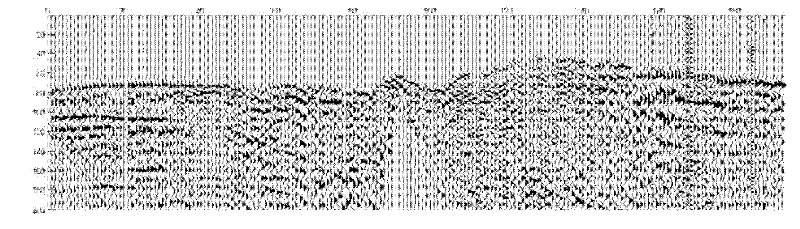

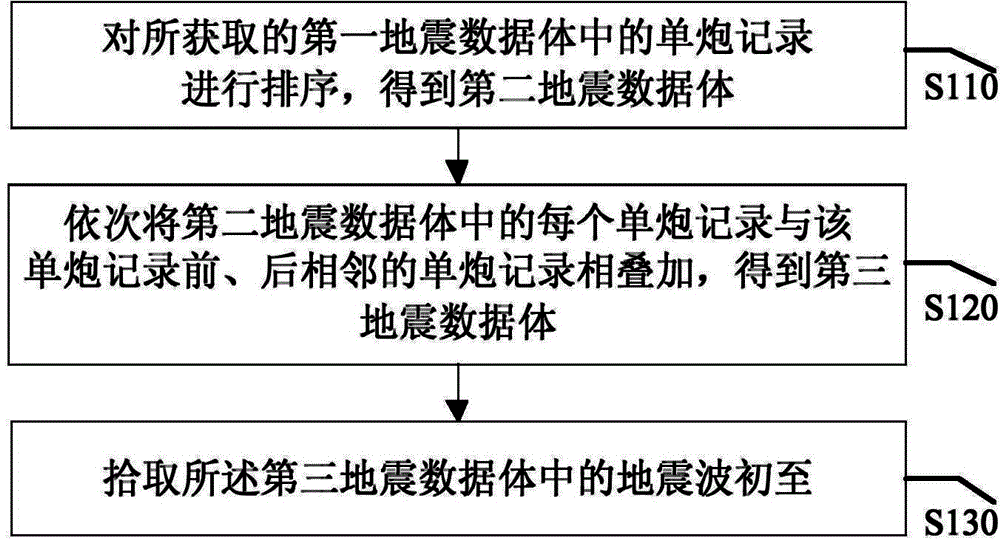

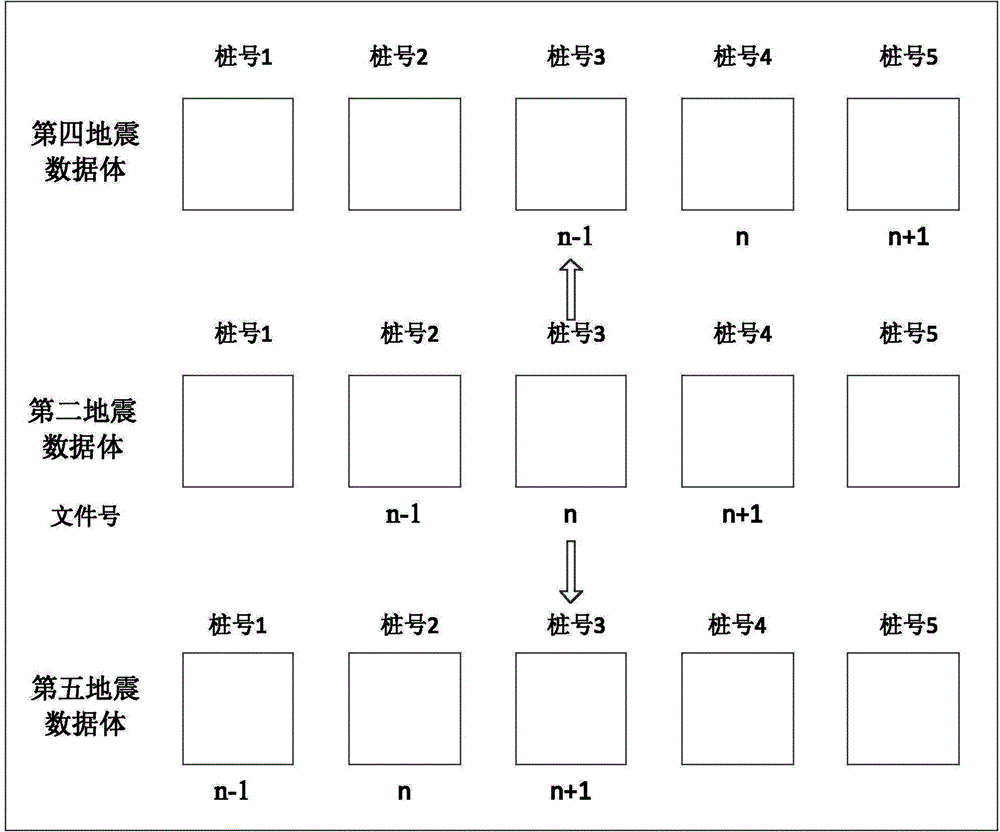

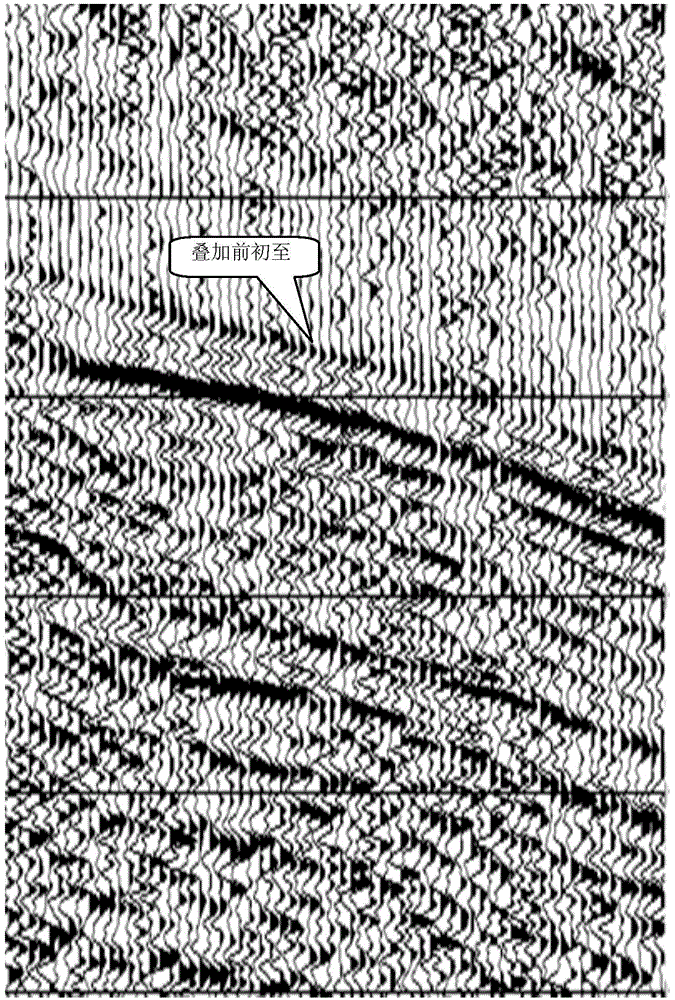

Method and device for picking up seismic wave first arrival

ActiveCN104932011AImprove signal-to-noise ratioImprove picking accuracySeismic signal processingSingle shotSeismic wave

The invention discloses a method and a device for picking up seismic wave first arrival. The method comprises steps of sorting single-shot records in an obtained first earthquake data body to obtain second earthquake data, superposing each single-shot data in the second earthquake data body with adjacent single-shot records before and after the single-shot data to obtain a third earthquake data body, and picking up the seismic wave first arrival in the third earthquake data body. The method and the device for picking up seismic wave first arrival can improve the pick-up precision of the seismic wave first arrival.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

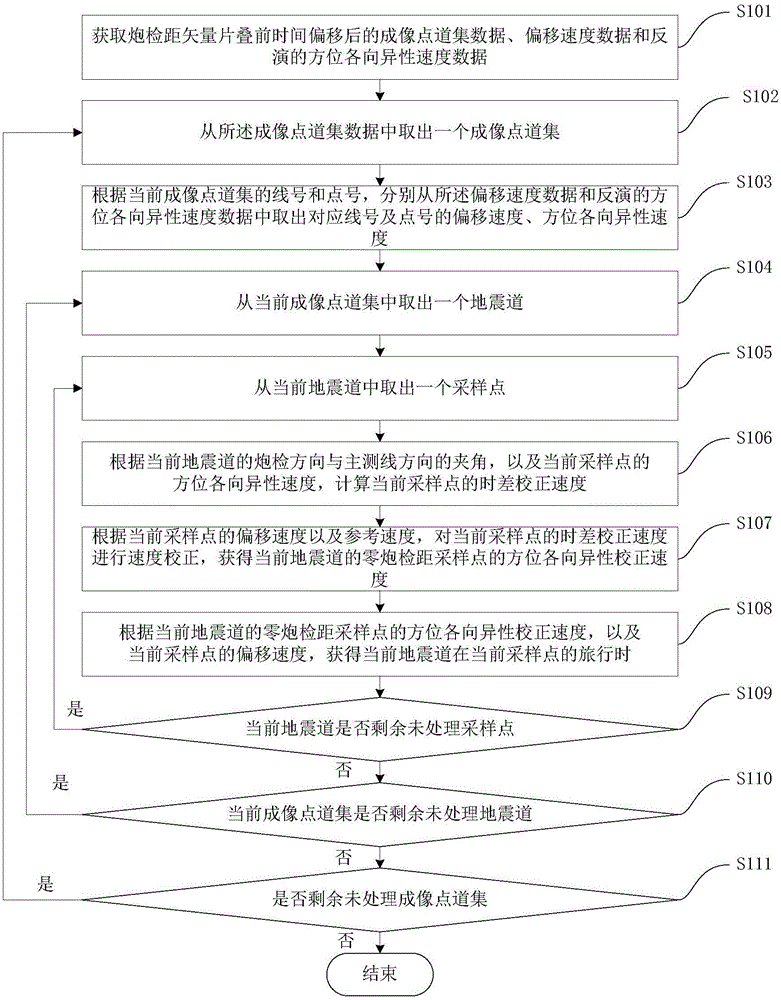

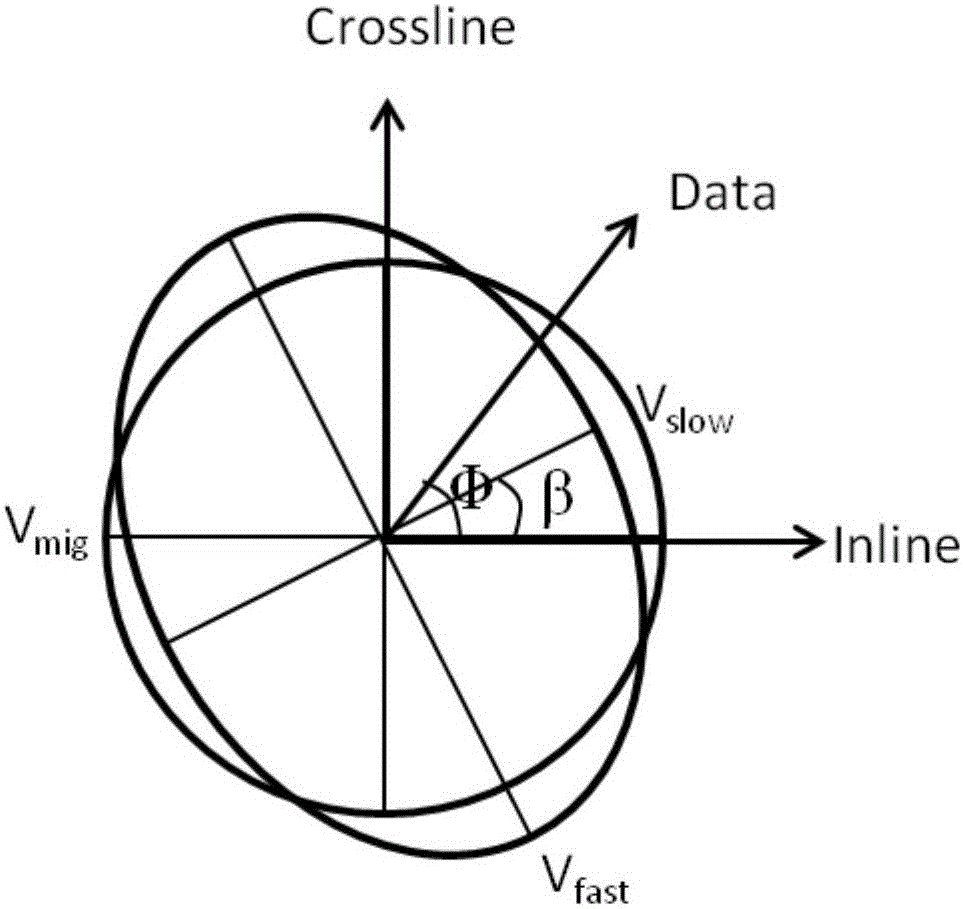

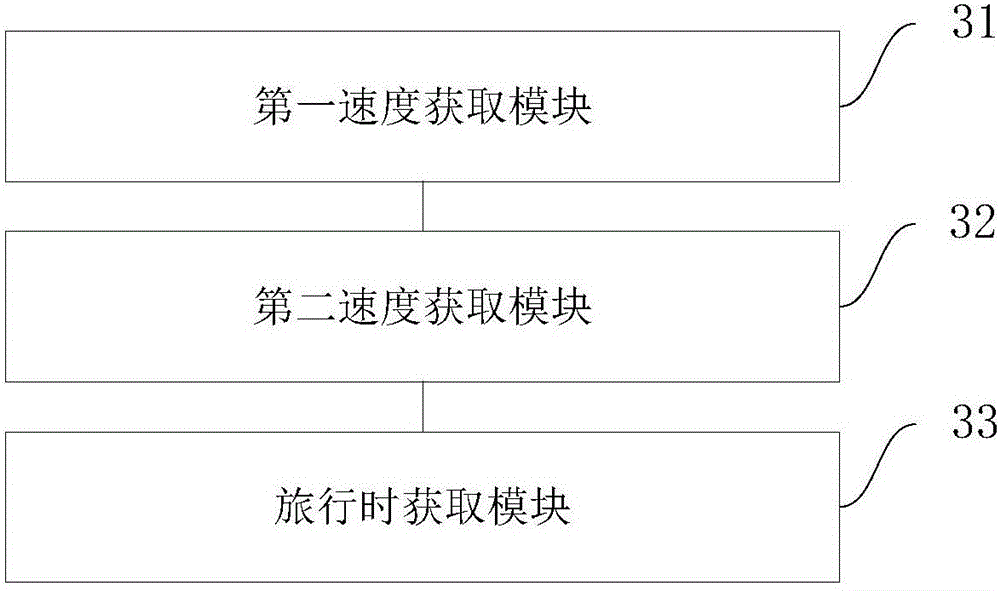

Residual time difference correction method and device of azimuthal anisotropy

ActiveCN106199717AImprove picking accuracyImprove processing efficiencySeismic signal processingCorrection methodTime difference

The invention provides a residual time difference correction method and device of azimuthal anisotropy. The method comprises that according to the included angle between a shot direction of a present seismic trace and the direction of a main measuring line as well as the azimuthally anisotropic speed of a present sampling point of the present seismic trace, a time difference correction speed of the present sampling point is calculated; according to the offset speed of the present sampling point and reference speed, the time difference correction speed of the present sampling point is corrected, and an azimuthally anisotropic correction speed of a zero-offset sampling point of the present seismic trace is obtained; and according to the azimuthally anisotropic correction speed of the zero-offset sampling point of the present seismic trace as well as the offset speed of the present sampling point, a sampling point value, when the present sampling point travels, of the present seismic trace at the position of travelling is obtained and serves as a result of residual time difference correction of azimuthal anisotropy. The processing efficiency and precision of residual time difference correction of azimuthal anisotropy are improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

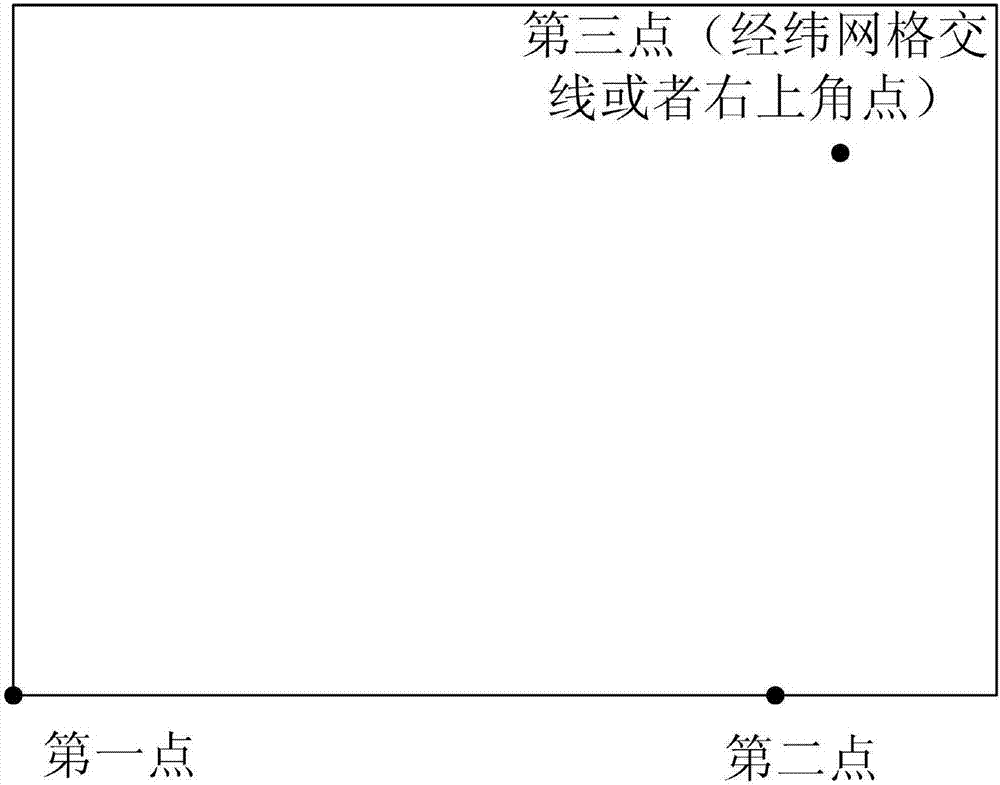

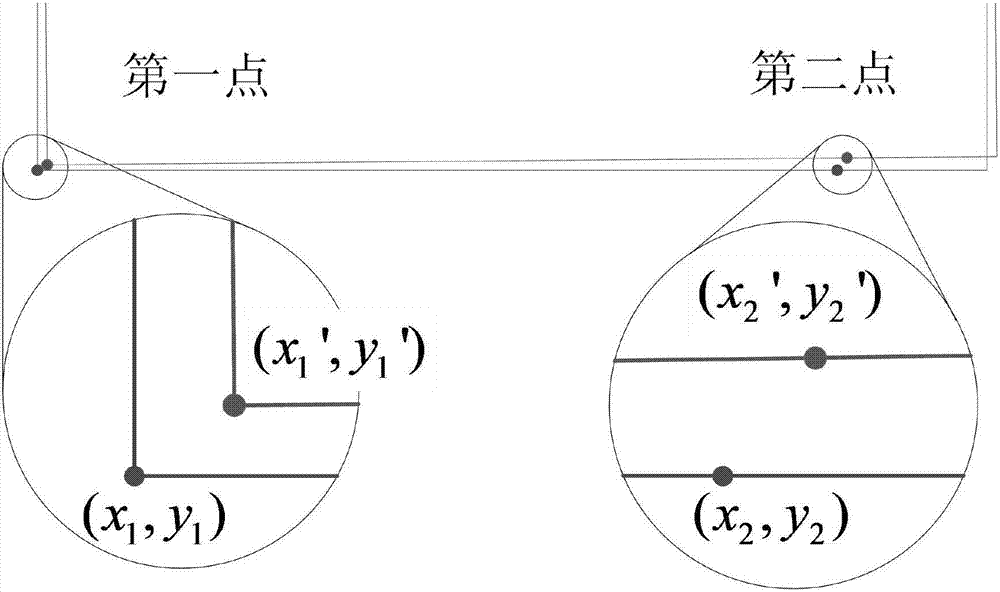

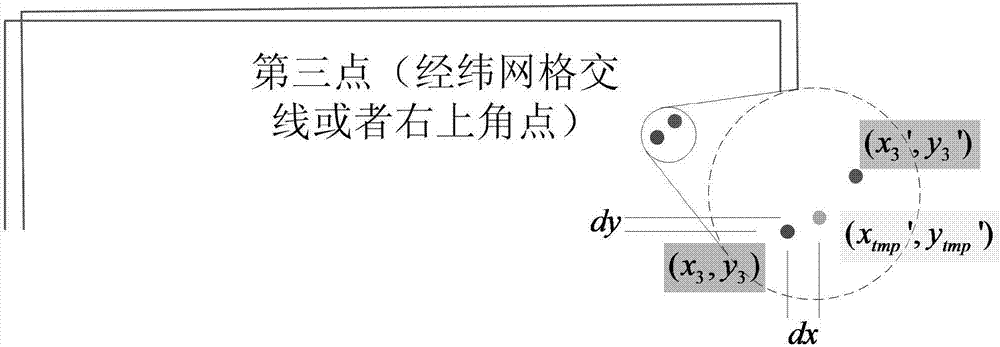

Method used for paper chart correction

ActiveCN107036628AHigh precisionImprove picking accuracyNavigational calculation instrumentsComputer graphics (images)Errors and residuals

The invention relates to a method used for paper chart correction. The method is characterized in that the method comprises the following steps that excursions and rotation errors generated during the placement of a chart are corrected by two calibrated points; deformation errors of the paper chat are corrected by three calibrated points. According to the method, a distortional paper chart coordinate system or a coordinate system out of position in placing can form mapping with a coordinate system of actual placement, and when plotting a position coordinate of a plotting light dot or a paper chart pick point, through mapping transformation, the light dot plotting indication precision and the coordinate pick precision can be improved; through the selection of two position points, two sets of theoretical position coordinates and actual position coordinates are obtained, and the rotation errors and moving errors generated by placing the paper chart are achieved; through the selection of three position points, three sets of theoretical position coordinates and actual position coordinates are obtained, and the rotation errors, the moving errors and the deformation errors of the paper chart are completed.

Owner:TIANJIN NAVIGATION INSTR RES INST

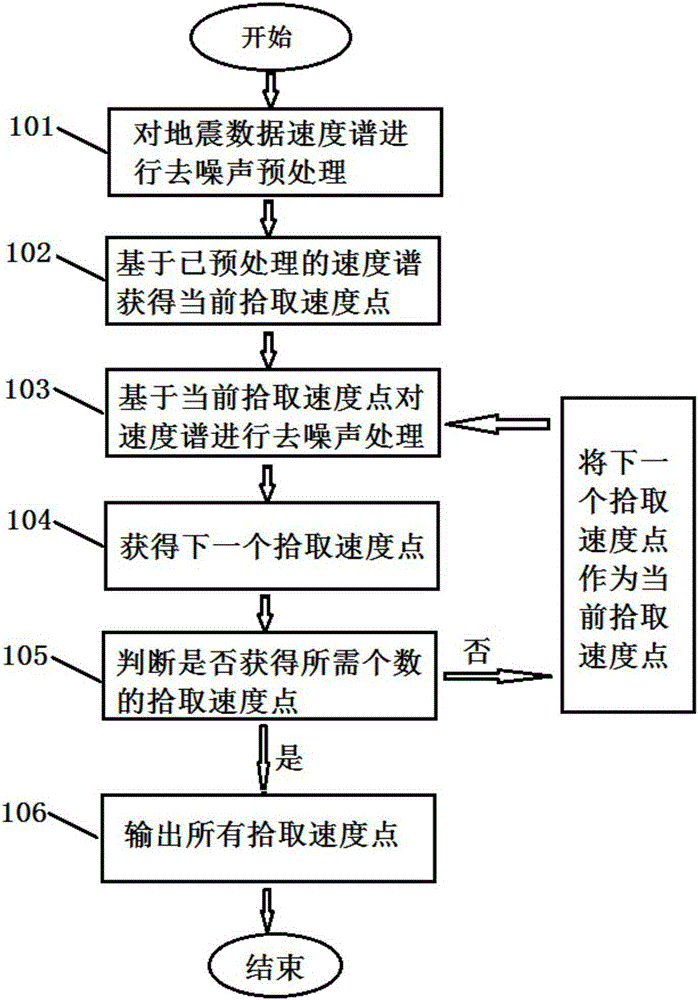

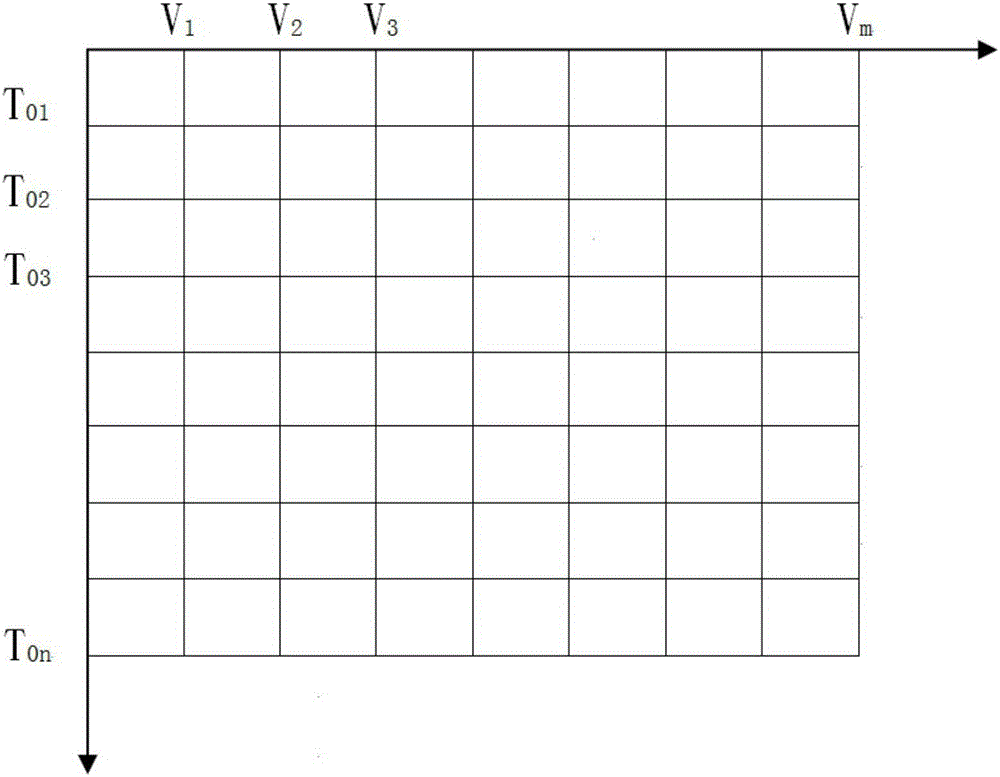

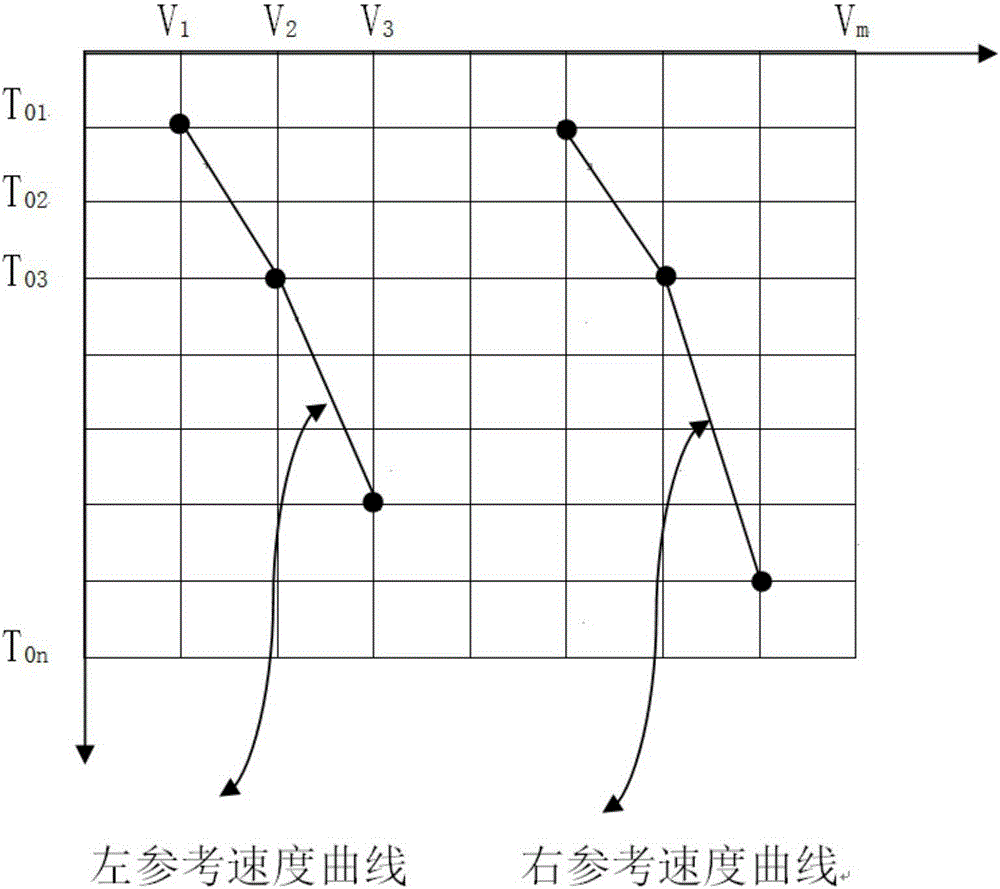

Seismic data speed spectrum automatic pickup method and device

ActiveCN106199693AImprove picking accuracySeismic signal processingVibration amplitudeVelocity spectrum

The invention discloses a seismic data speed spectrum automatic pickup method and device. The method comprises the following steps: a speed spectrum of seismic data of a common midpoint is subjected to denoising preprocessing operation; based on the pretreated speed spectrum, a position of a maximum vibration amplitude near a current time point is obtained as a current pickup speed point; based on the current pickup speed point, the speed spectrum is subjected to denoising processing operation; based on the post-denoising-processing speed spectrum, a position of a maximum vibration amplitude near a next time point is obtained as a next pickup speed point; whether a required number of pickup speed points are obtained is determined; if the required number of pickup speed points are not obtained, the next pickup speed point is used as the current pickup speed point, and the current step goes back to the previous step of subjecting the speed spectrum to the denoising processing operation based on the current pickup speed point; if the required number of pickup speed points are obtained, all of the pickup speed points are output, and only pickup speed points having speed values that rise over time are kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

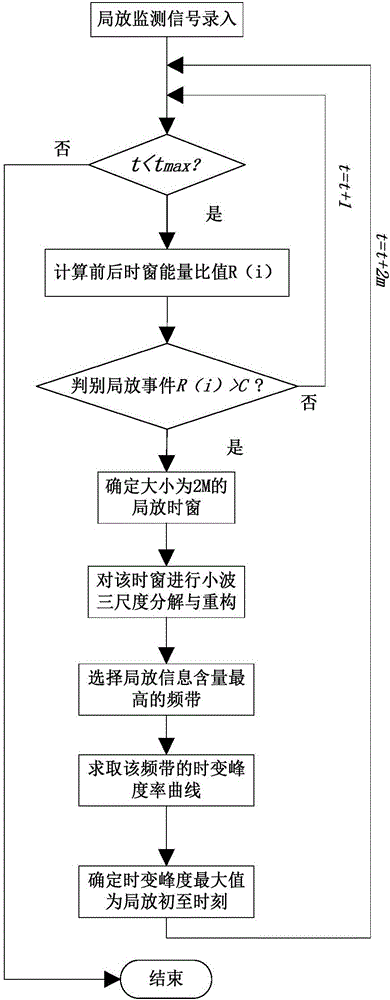

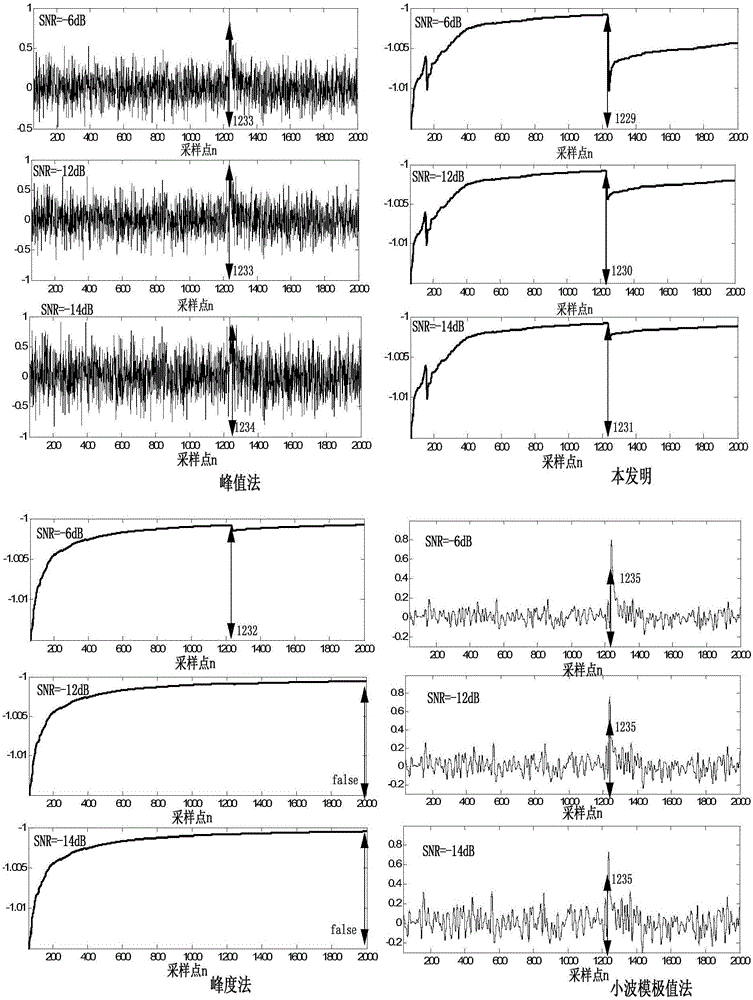

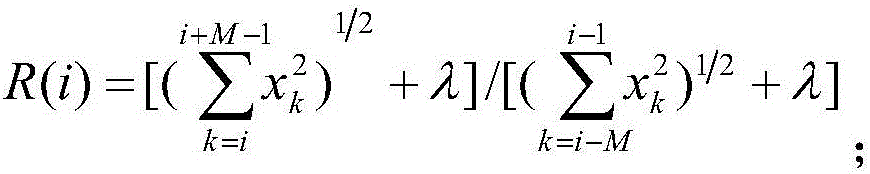

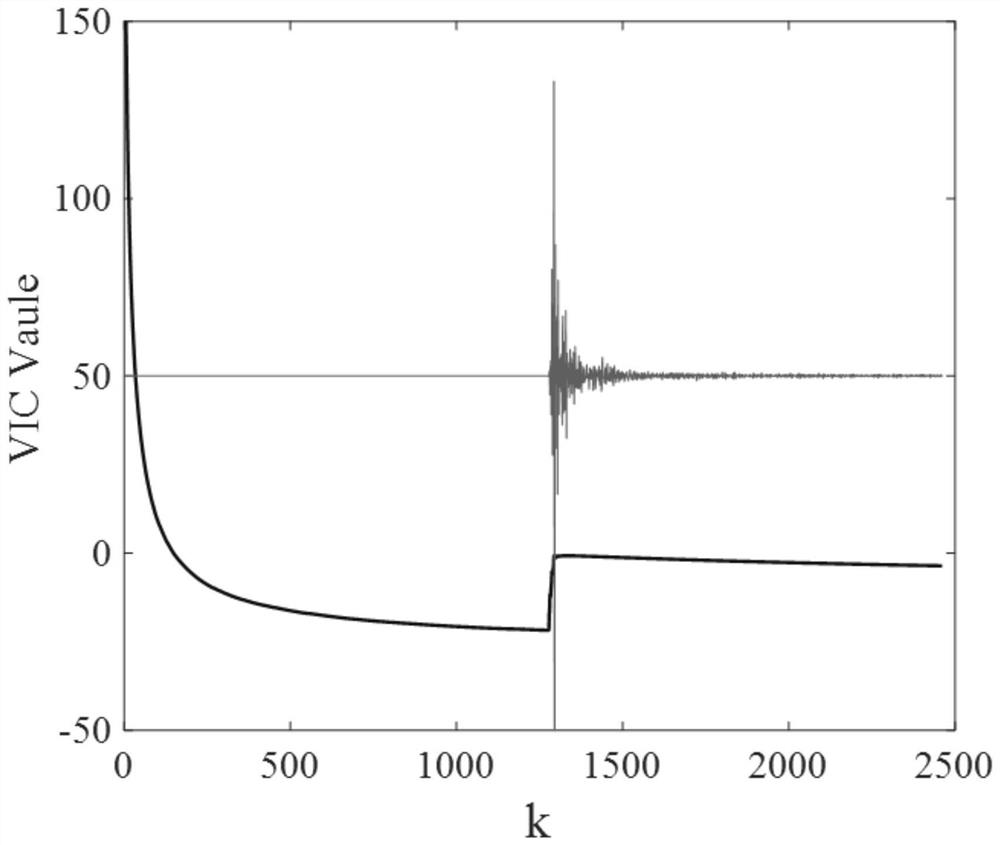

Partial discharge pulse first arrival moment online pickup method

InactiveCN106771928AImprove picking accuracyStrong noise adaptabilityTesting dielectric strengthDecompositionAdaptive capacity

The invention discloses a partial discharge pulse first arrival moment online pickup technology based on wavelet packet kurtosis, and belongs to the field of signal processing, wherein the technology is particularly suitable for online high-precision pickup of the partial discharge pulse first arrival moment of a high-voltage cable. Particularly, the method includes the steps that the before and after time window energy ratio R of a monitoring sequence is calculated, the time window happening during partial discharge is determined through the time window energy ratio curve, wavelet packet three-dimensional decomposition and reconstruction are carried out on the time window happening in the determined partial discharge pulse to extract the partial discharge pulse, and finally a kurtosis algorithm is used for online high-precision pickup of the partial discharge pulse first arrival moment. Compared with the single kurtosis method, the currently existing peak value method and the wavelet transform modulus extremum method, the partial discharge pulse first arrival moment online pickup method has higher adaptive capacity to noise and has important engineering application value.

Owner:HENAN POLYTECHNIC UNIV

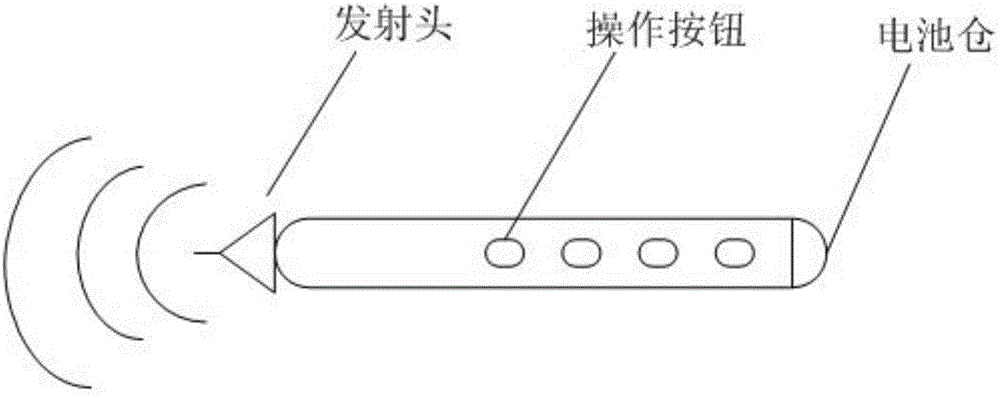

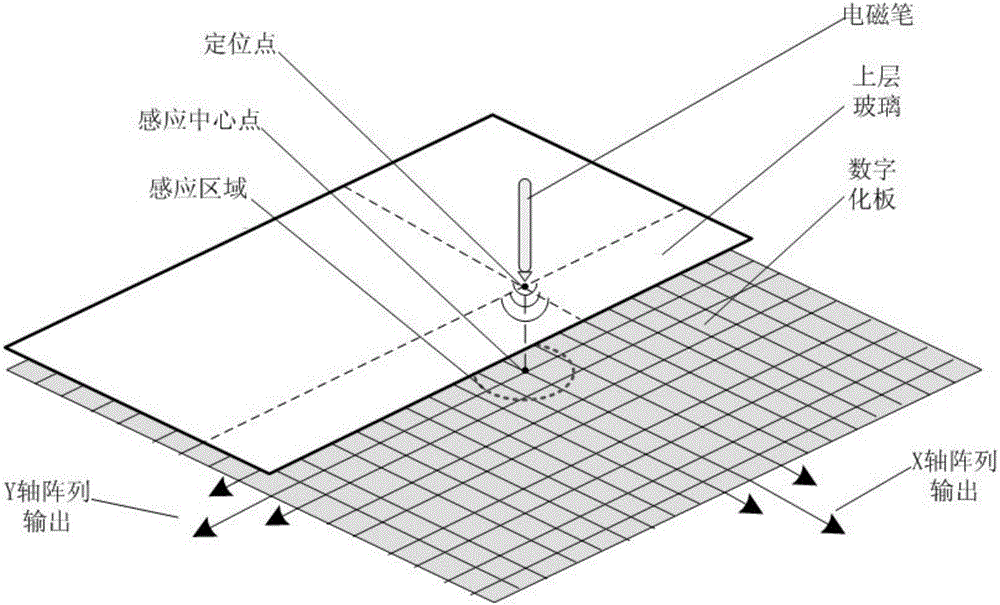

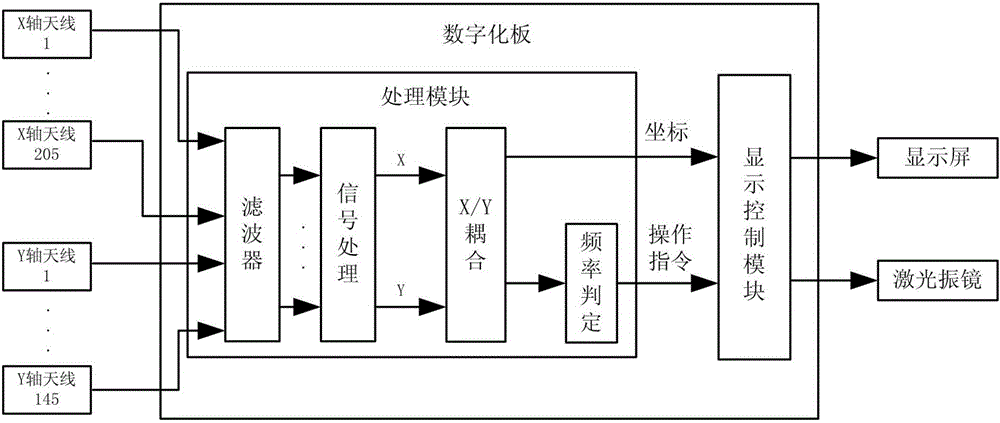

Method for drawing paper chart based on active electro-magnetic induction pen

ActiveCN106767839AImprove accuracyImprove display capabilitiesNavigational calculation instrumentsPoint coordinate measurementsElectromagnetic inductionMagnetic signal

The invention relates to a method for drawing a paper chart based on an active electro-magnetic induction pen. The method is characterized by comprising the following steps: triggering a starting point on the paper chart by a pen point of the active electro-magnetic induction pen and sending an electro-magnetic signal frequency F1; extracting a coordinate of the starting point by a digital plate; triggering a target point by the pen point of the active electro-magnetic induction pen and sending an electro-magnetic signal frequency F2; extracting the coordinate of the target point by the digital plate; operating a ship route drawing button of the active electro-magnetic induction pen and sending an electro-magnetic signal frequency F4; and drawing a ship route according to the recorded coordinate of the starting point and the coordinate of the sequential target point after the signal is detected by the digital plate. According to the invention, an electro-magnetic oscillation signal in a specific frequency is sent by the active electro-magnetic induction pen, an X / Y axial antenna array on the digital plate is used for receiving the signal, a processing module is used for processing and calculating the received signal, the specific drawing operation is completed and the quick positioning for the target is realized, so that the picking accuracy for the position information is increased and the target tracking and posture display capacities are promoted.

Owner:TIANJIN NAVIGATION INSTR RES INST

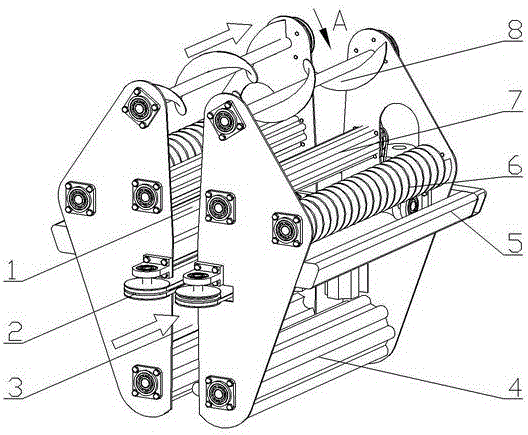

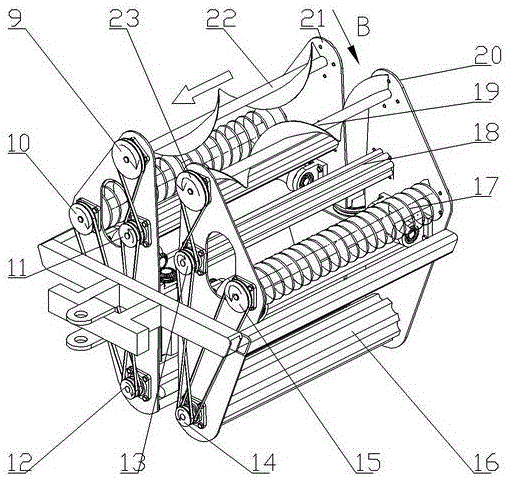

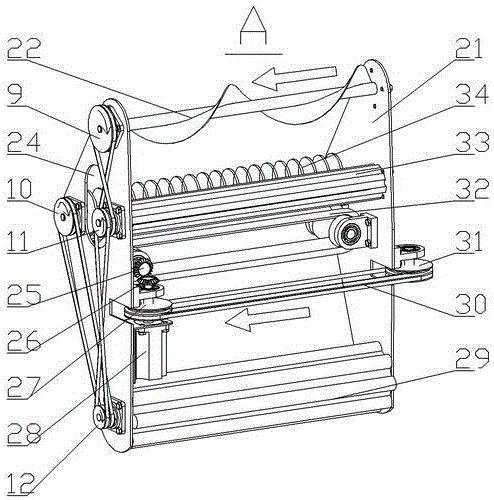

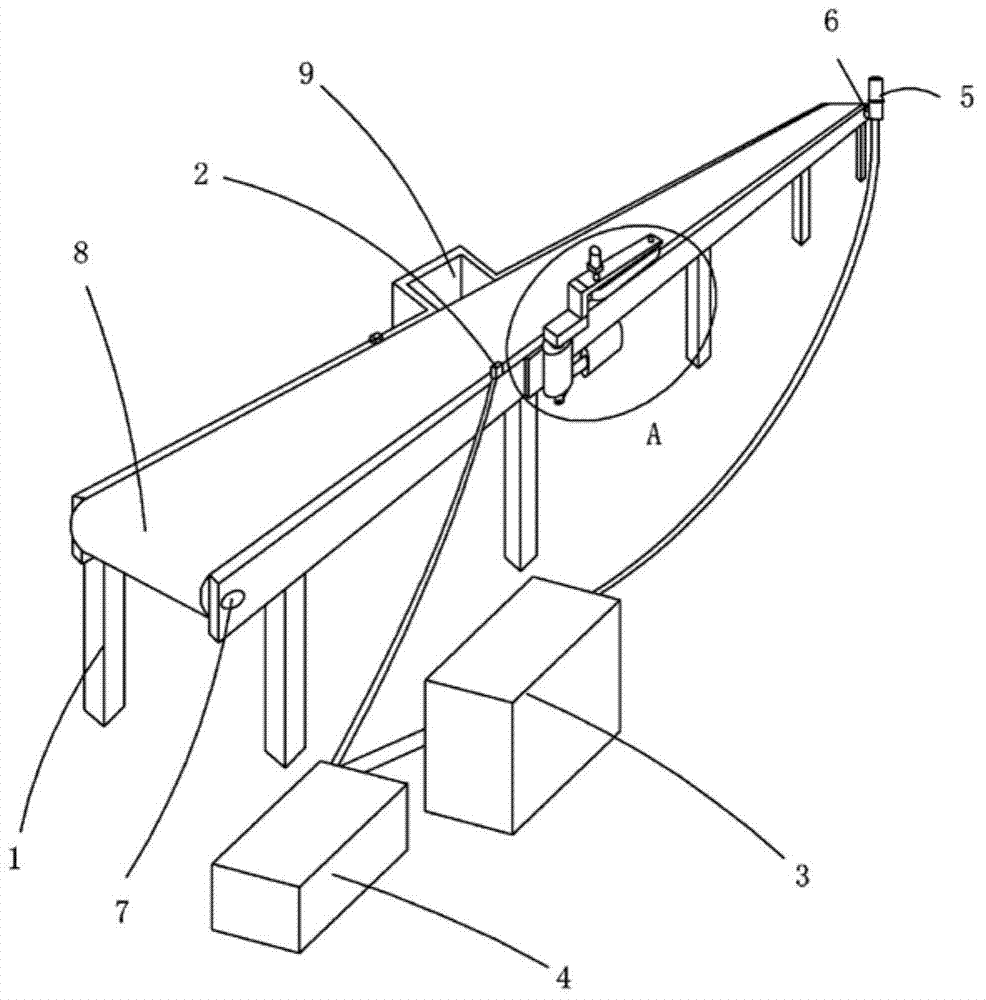

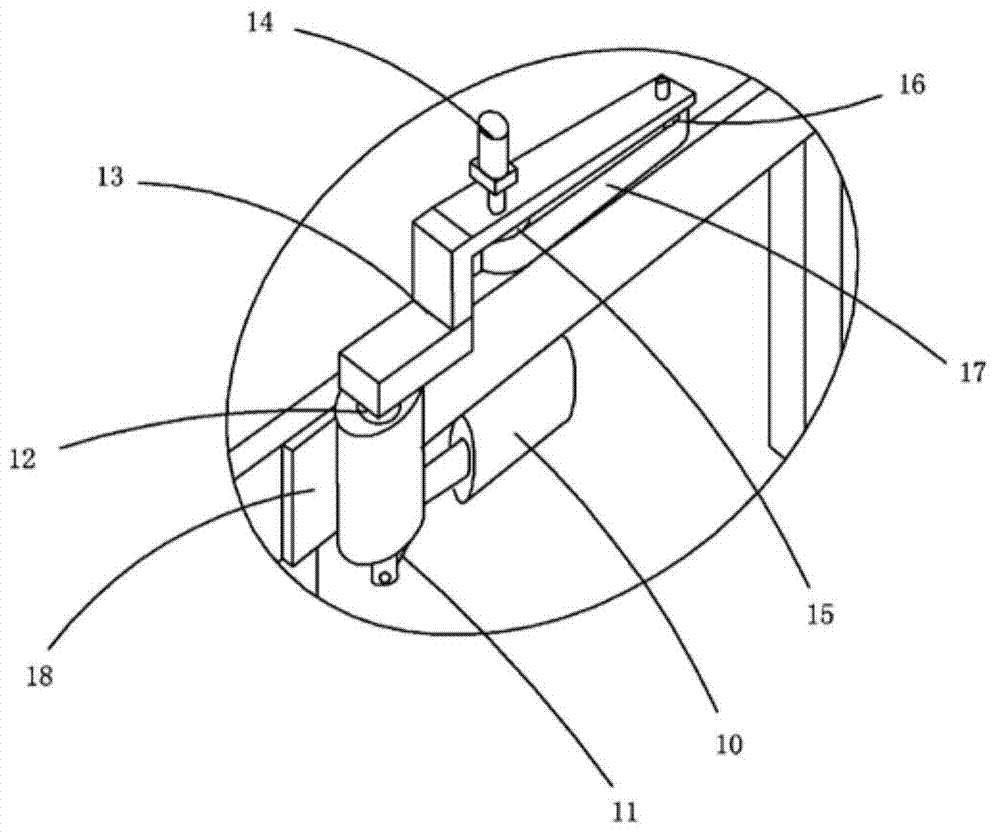

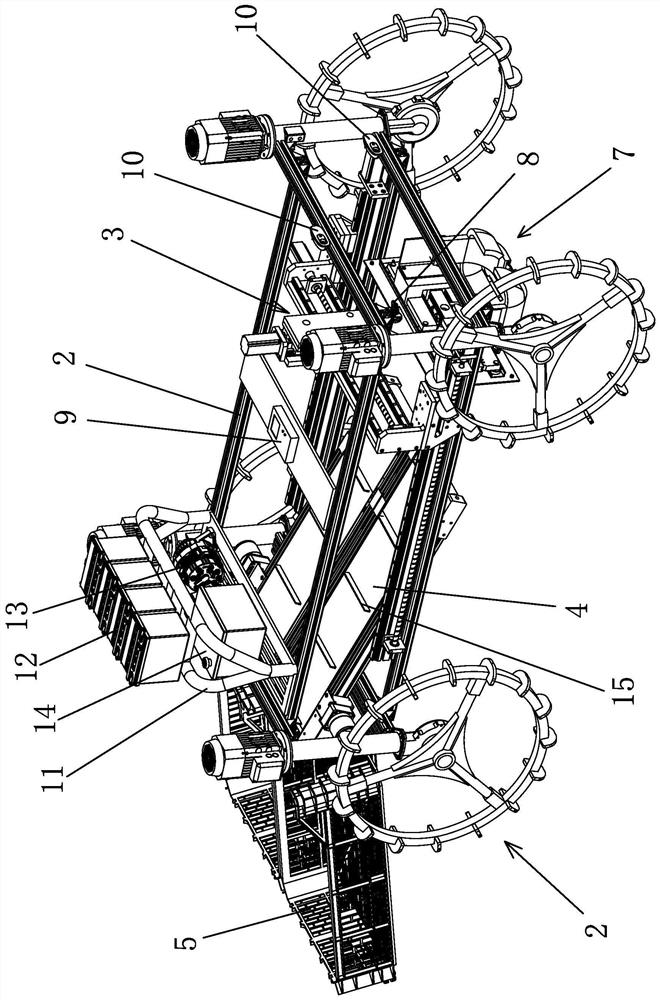

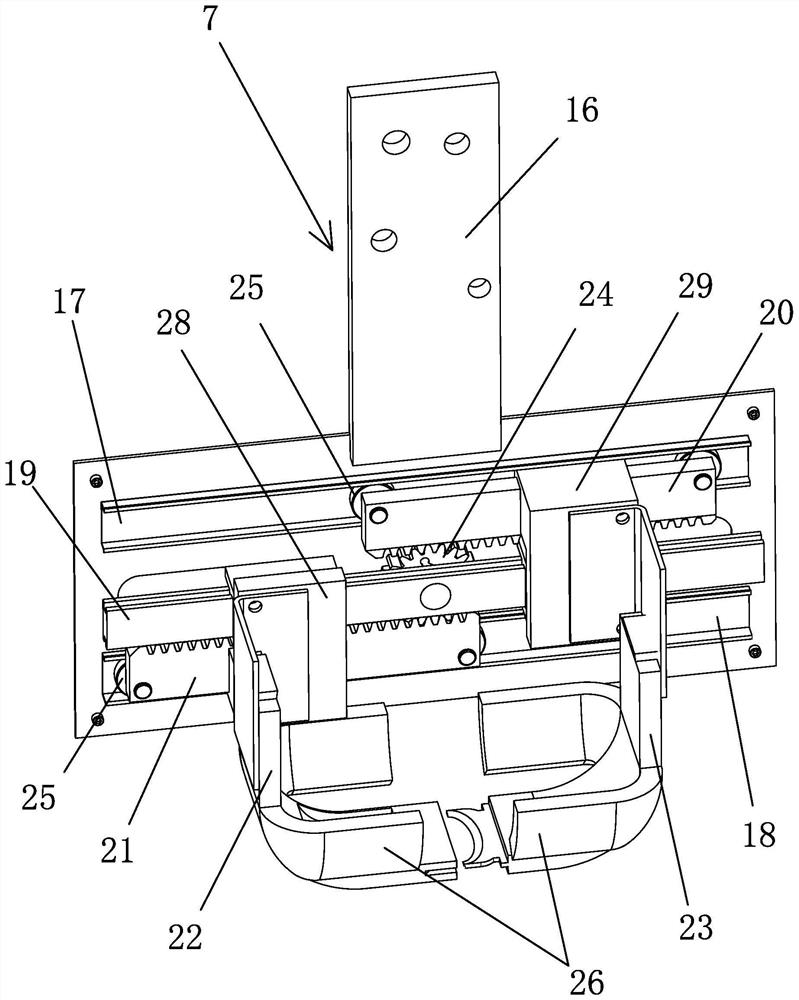

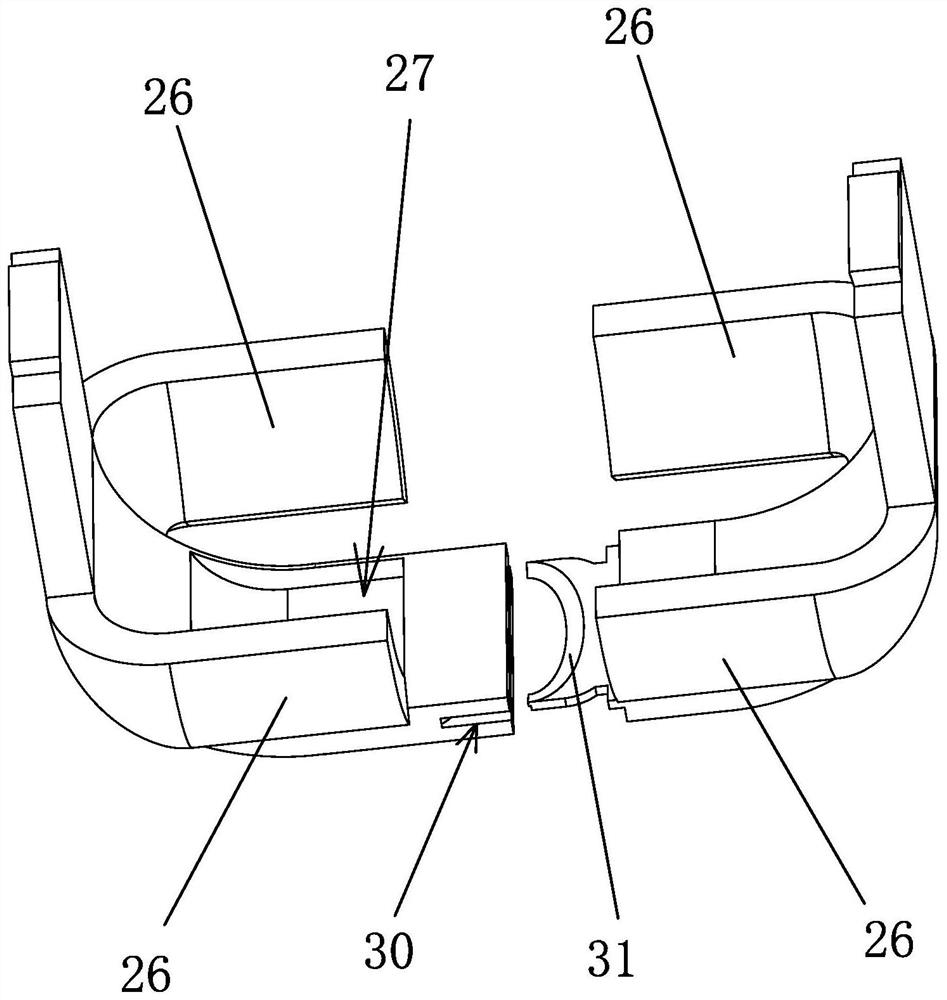

Orientating, spike-picking and peel-stripping device for corn bionic harvesting

ActiveCN106717583AImprove picking accuracyImprove the efficiency of peeling operationsThreshersPull forceEngineering

The invention discloses an orientating, spike-picking and peel-stripping device for corn bionic harvesting. The orientating, spike-picking and peel-stripping device comprises an orientating mechanism, a spike-picking mechanism, a peel-stripping mechanism, a conveying mechanism, a clamping mechanism, a stem pulling mechanism and a rack, wherein the orientating mechanism is fixedly arranged on the upper part of the rack; the spike-picking mechanism is fixedly arranged above the middle part of the rack; the peel-stripping mechanism is fixedly arranged at the outer side of the middle part of the rack; the conveying mechanism is fixedly arranged below the middle of the spike-picking mechanism and the middle of the peel-stripping mechanism; the clamping mechanism is fixedly arranged below the middle of the rack; the stem pulling mechanism is fixedly arranged on the lower part of the rack; a stem pulling concave roller and a stem pulling convex roller are coupled with each other, so that stalks bear downward pulling force; a spike-picking concave roller and a spike-picking convex roller reversely rotate to realize spike picking; a left rotary orientating auger and a right rotary orientating auger reversely rotate for forming orienting thrust on corn spikes; and a left rotary peel stripping roller is matched with the spike-picking concave roller, and a right rotary peel stripping roller and the spike-picking concave roller are matched, so that orientating peel-stripping operation is completed. The orientating, spike-picking and peel-stripping device is high in spike-picking precision, high in peel-stripping efficiency and is less in spike loss.

Owner:SHANDONG JUMING MASCH CO LTD

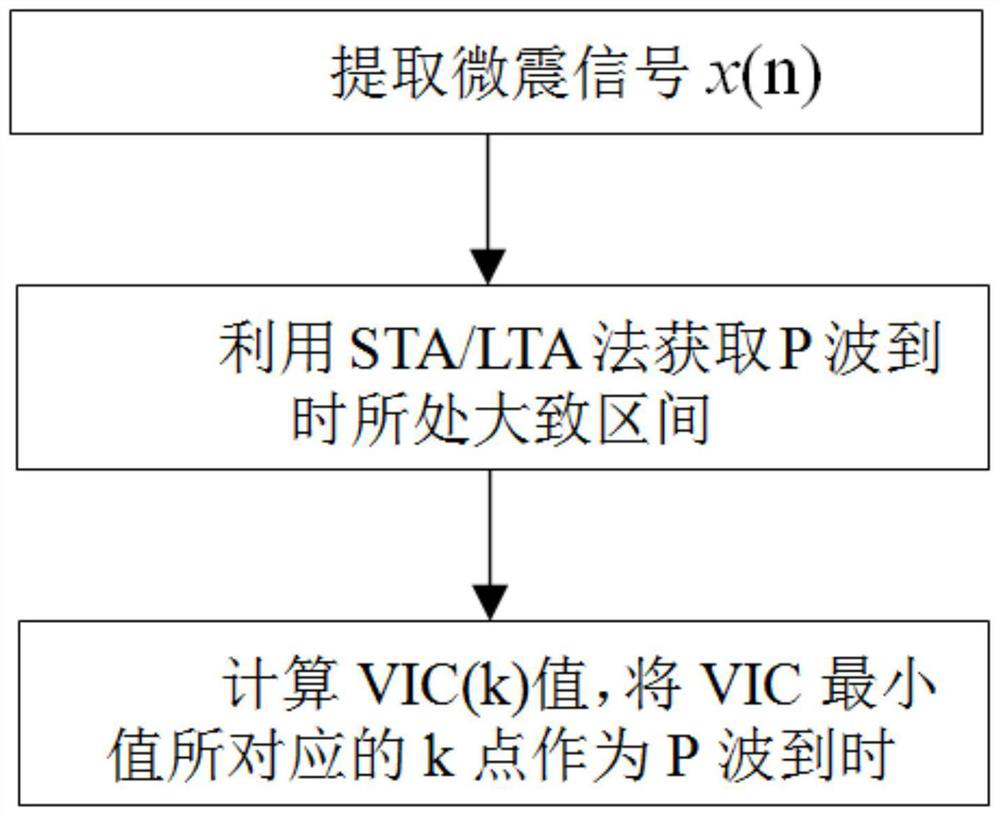

P-wave arrival time pickup method based on long and short time windows and AR model variance surge effect

PendingCN112526602AImprove picking accuracyAccelerateSeismic signal processingEngineeringAutologistic regression

The invention provides a P-wave arrival time pickup method based on long and short time windows and an AR model variance surge effect. The method comprises the steps of extracting micro-seismic signalwaveform data, preliminarily judging the interval of P wave arrival time, picking up the P wave arrival time and the like. According to the method, the interval where the P wave arrives and the auto-regression model variance surge effect caused by the difference between the signal and the noise level are preliminarily judged by means of the STA / LTA method, the pickup error rate is greatly reduced, the pickup efficiency is improved, and meanwhile the P wave pickup stability is also enhanced. The method has the advantages of being high in picking precision, high in speed, good in stability, high in applicability and the like.

Owner:CHONGQING UNIV

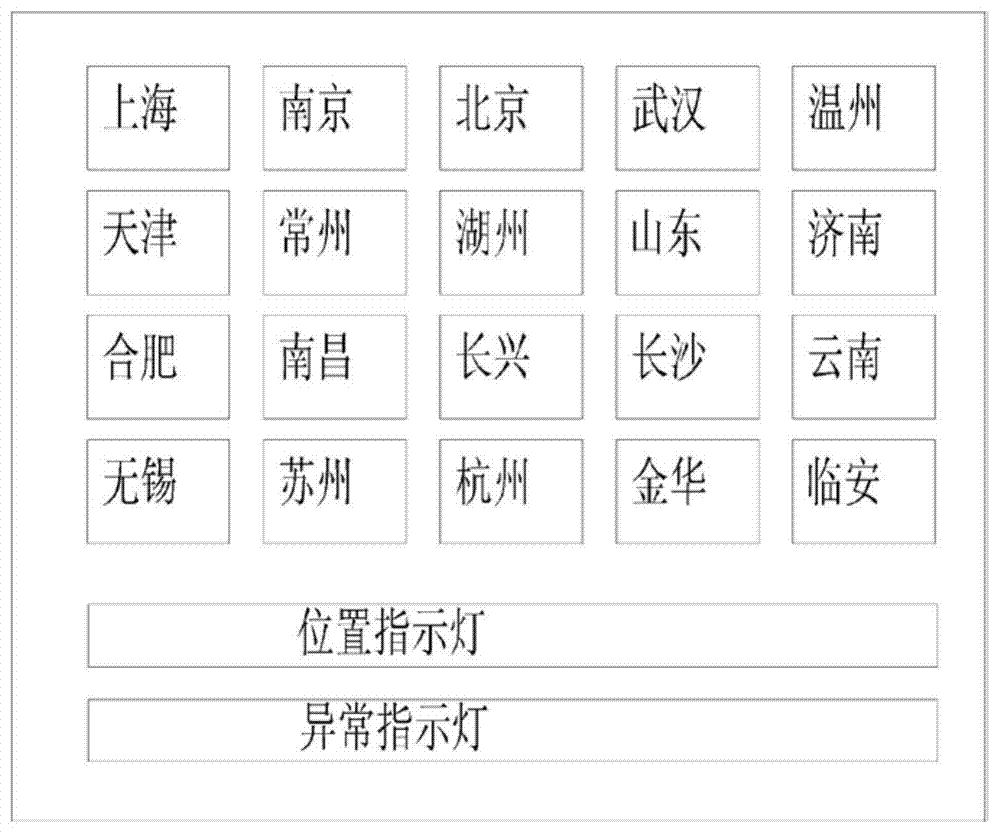

Fully-automatic sorting machine

InactiveCN103920649ATo achieve the purpose of automatic sortingImprove picking accuracySortingMotor driveDrive shaft

The invention relates to a fully-automatic sorting machine which is characterized in that two ends of a rack are provided with a driving shaft and a driven shaft, wherein a driving motor is connected with the driving shaft; the driving shaft is connected with the driven shaft through a belt; a group of photoelectric sensors and sorting mechanisms are arranged on the front side of the rack at certain intervals; outlets, corresponding to the sorting mechanisms, are formed in the rear side of the rack; a destination button, an abnormal indication lamp and a position indication lamp, corresponding the respective outlets, are arranged on a touch screen; goods are arranged on the belt, the corresponding buttons on the touch screen are pressed according to the sorting addresses of the goods, and the driving motor drives the belt to rotate so as to cause the goods to advance; a main controller controls the corresponding photoelectric sensors, when the photoelectric sensor senses the corresponding goods, sensing signals are fed back to the main controller, the main controller controls to enable a cylinder to drive a connecting rod, and a shifting rod is driven by a rotating shaft to rotate so as to block the goods; meanwhile, a feeding motor drives to enable a feeding belt to rotate to drive the advancing goods to be conveyed from the corresponding outlets, so that the sorting purpose is achieved.

Owner:HUZHOU WUXING LINGDONG ELECTROMECHANICAL EQUIP MFG PLANT

Broccoli harvesting device

InactiveCN114557190AImprove picking accuracyImprove stabilityHarvestersClosed circuit television systemsAgricultural scienceControl system

The invention provides a broccoli harvesting device, and belongs to the technical field of agricultural machinery. The broccoli harvesting device comprises a wheel mechanism and a rack, a picking mechanism, a conveying mechanism and a collecting frame are arranged on the rack, the picking mechanism is arranged at the front end of the rack, the conveying mechanism is arranged at the middle-rear end of the rack, the front end of the conveying mechanism is close to the picking mechanism, and the rear end of the conveying mechanism is connected with the collecting frame; the collecting frame is arranged at the tail end of the rack, the picking mechanism comprises a three-axis moving suite, a cutter assembly, a first camera and a control system, the first camera is arranged on the upper portion of the cutter assembly and faces a notch of the cutter assembly, and the cutter assembly is installed on the rack through the three-axis moving suite; the three-axis moving suite, the cutter assembly, the first camera and the conveying mechanism are all electrically connected with the control system, and the control system is installed on the rack. The broccoli picking device is stable in picking effect, suitable for picking broccoli with different thicknesses and heights and high in picking efficiency.

Owner:TAIZHOU UNIV

Hexapod robot for fruit and vegetable picking and operating method thereof

The invention relates to a hexapod robot for fruit and vegetable picking and an operating method thereof. The hexapod robot for fruit and vegetable picking is characterized by comprising a body and six mechanical legs arranged thereof; the body is also provided with a picking mechanical arm, a collecting box, a visual recognition module, a tracking sensor arrangement plate, a gyroscope module, a control module and a power source. A picking claw is arranged at the tail end of the picking mechanical arm. Four mechanical legs are arranged at four corners of the body respectively; the other two mechanical legs are arranged symmetrically in the middle of the body. The movement mode of the hexapod robot is a leg mode; the hexapod robot is suitable for picking fruits and vegetables on a soft ground or severely uneven terrain, and has good flexibility; tracking sensors in rectangular arrangement are arranged on a lower plate of the body, and advancing may occur according to a preset path; thevisual recognition module is mounted on the picking mechanical arm, so that picking accuracy is improved; automatic picking on a relatively uneven terrain according to the set path is achieved; the hexapod robot has high practical value.

Owner:NORTHWEST A & F UNIV

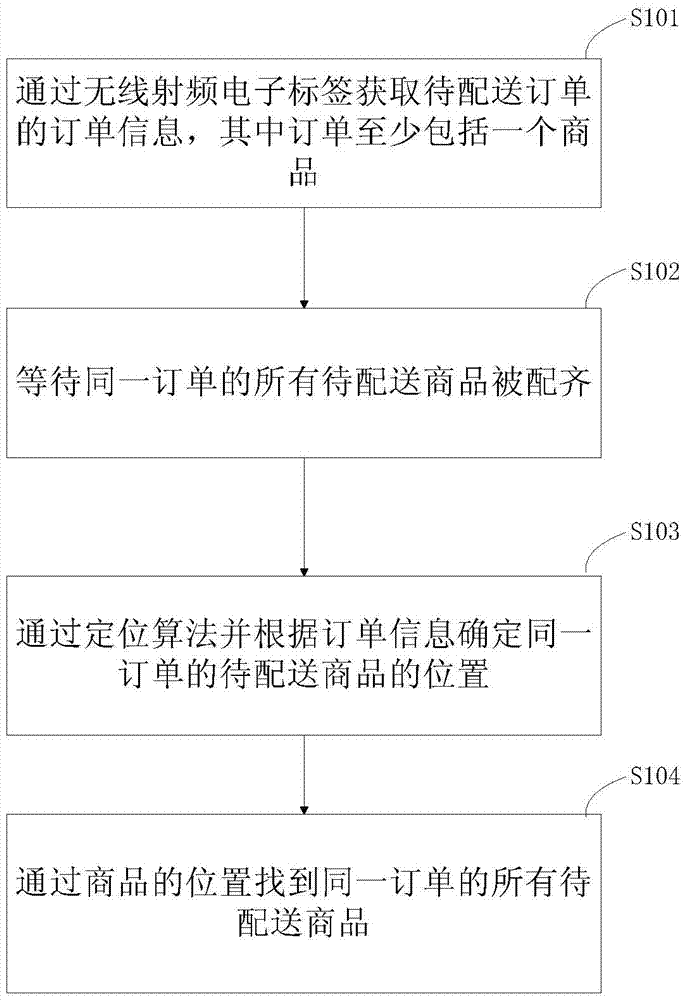

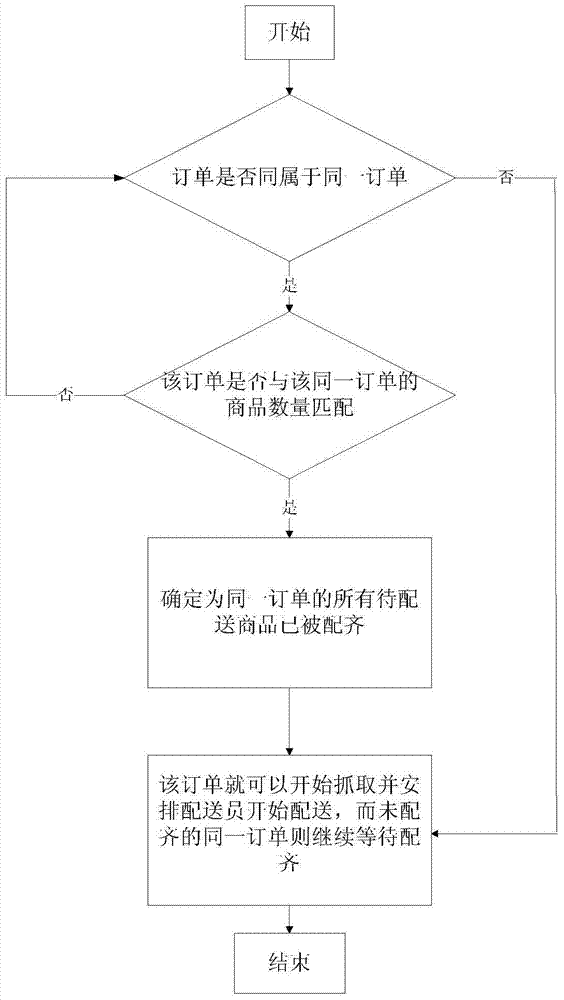

Delivery station express sorting method based on RF identification technology

PendingCN107025529AImprove picking efficiencyImprove picking accuracyCo-operative working arrangementsLogisticsComputer scienceWireless

The invention provides a delivery station express sorting method based on RF identification technology. The method comprises the steps of acquiring order information of a to-be-delivered order through a wireless RF electronic label, wherein the order comprises at least one commodity; waiting preparation of all to-be-delivered commodities of the same order; determining the positions of the to-be-delivered commodities of the same order through a positioning algorithm according to the order information; and finding out all the to-be-delivered commodities of the same order through the positions of the commodities. The delivery station express sorting method based on the RF identification technology can effectively improve commodity sorting efficiency and commodity sorting accuracy of a delivery station and furthermore reduces personnel labor intensity and package damage probability. As delivery time in the last one kilometer is reduced, user experience is improved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

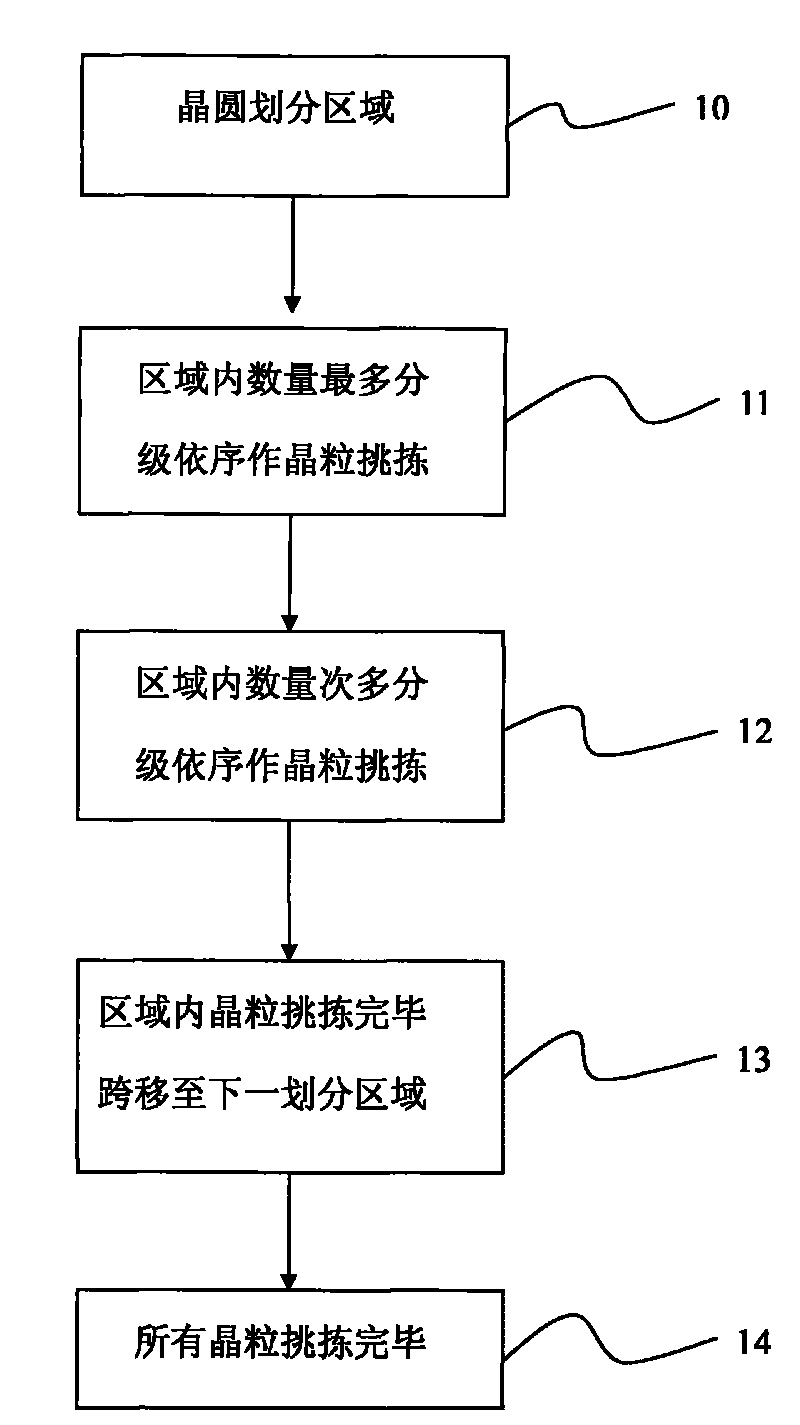

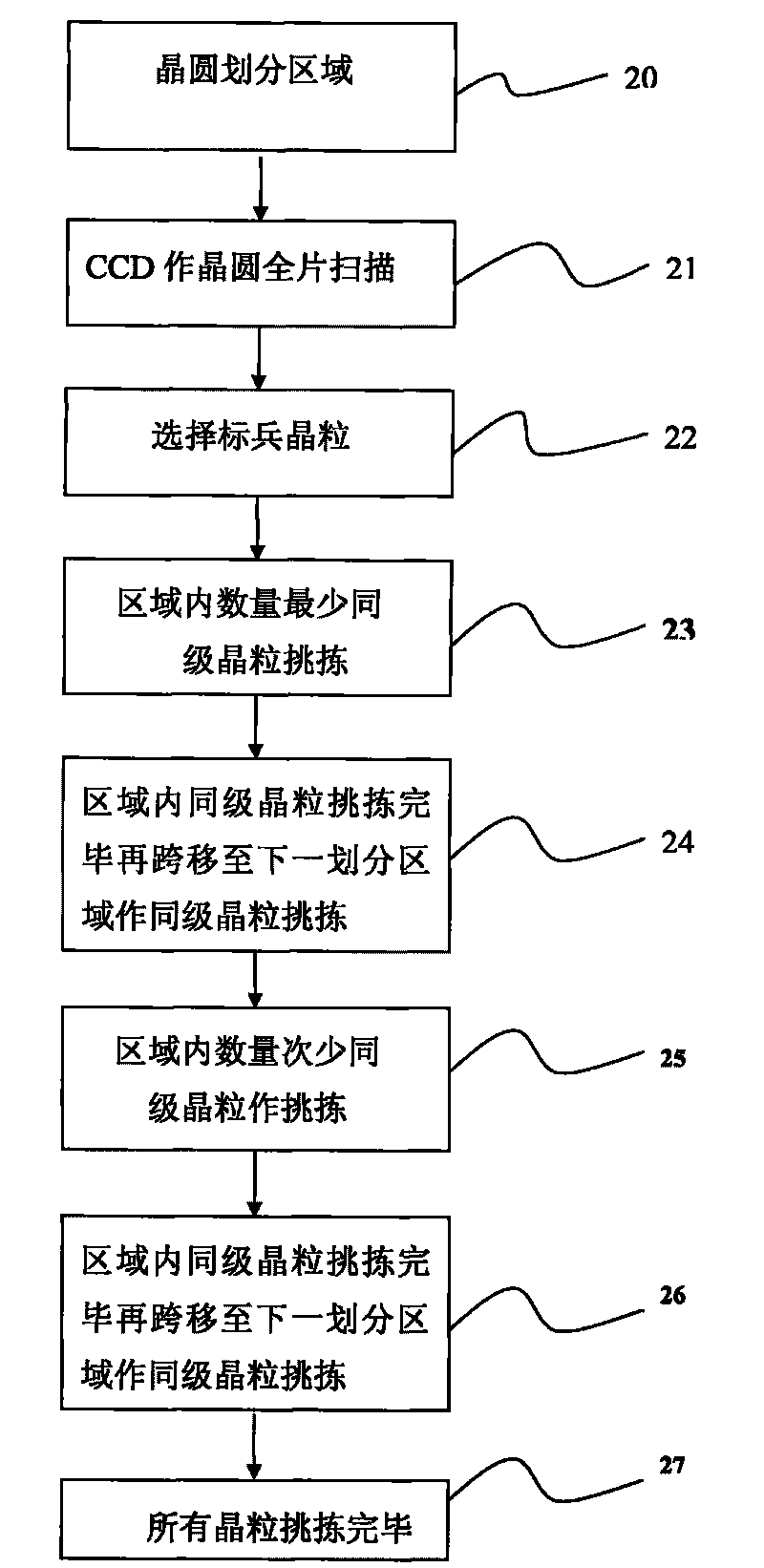

Method for picking model type crystal particle

ActiveCN101728227ASmall displacement deviationImprove picking accuracySemiconductor/solid-state device manufacturingPositioning systemPhysics

The invention relates to a method for picking model type crystal particles, comprising the following steps of: firstly providing a wafer fully distributed with crystal particles; obtaining a wafer map fully distributed with the crystal particles through a CCD system (image identifying and positioning system); dividing the wafer map into a plurality of dividing areas; recording the relative positions among the crystal particles (including the model type crystal particles) to be used as the basis reference of the displacement compensation correction of the crystal particles in the picking process of the crystal particles; then selecting crystal particles as the model type crystal particles from the centers of the several dividing areas of the plurality of dividing areas; then selecting bin crystal particles with the minimum crystal particle sum quantity to start to pick by using initial model type crystal particles in the dividing areas as starting points; then sequentially picking the bin crystal particles in all the dividing areas one by one in a model way; and repeating in such a way so as to completely pick all the crystal particles. The action of deflection compensation correction is needed because crystal particle deflection situations can be generated in the picking process of the crystal particles. By adopting the method, the crystal particles can be faster and more accurate picked.

Owner:YOUNGTEK ELECTRONICS

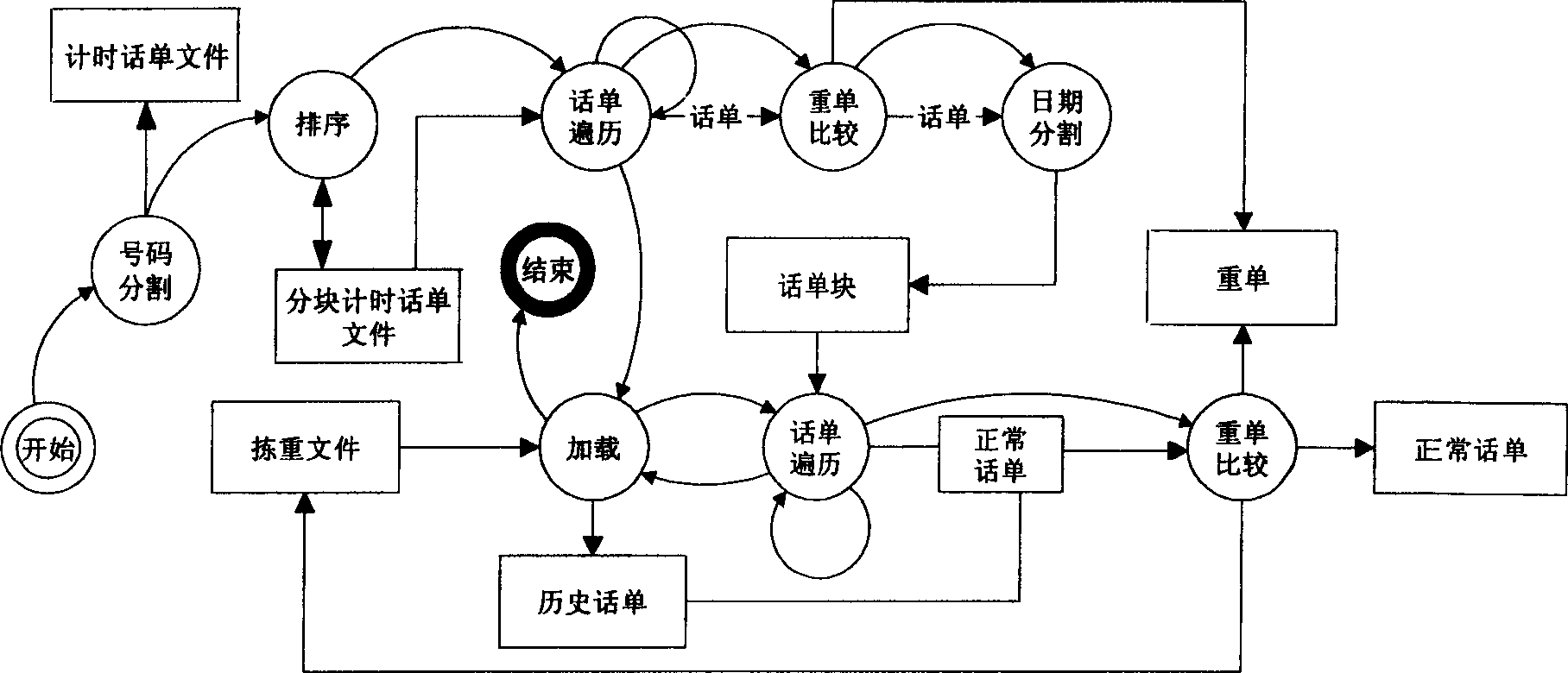

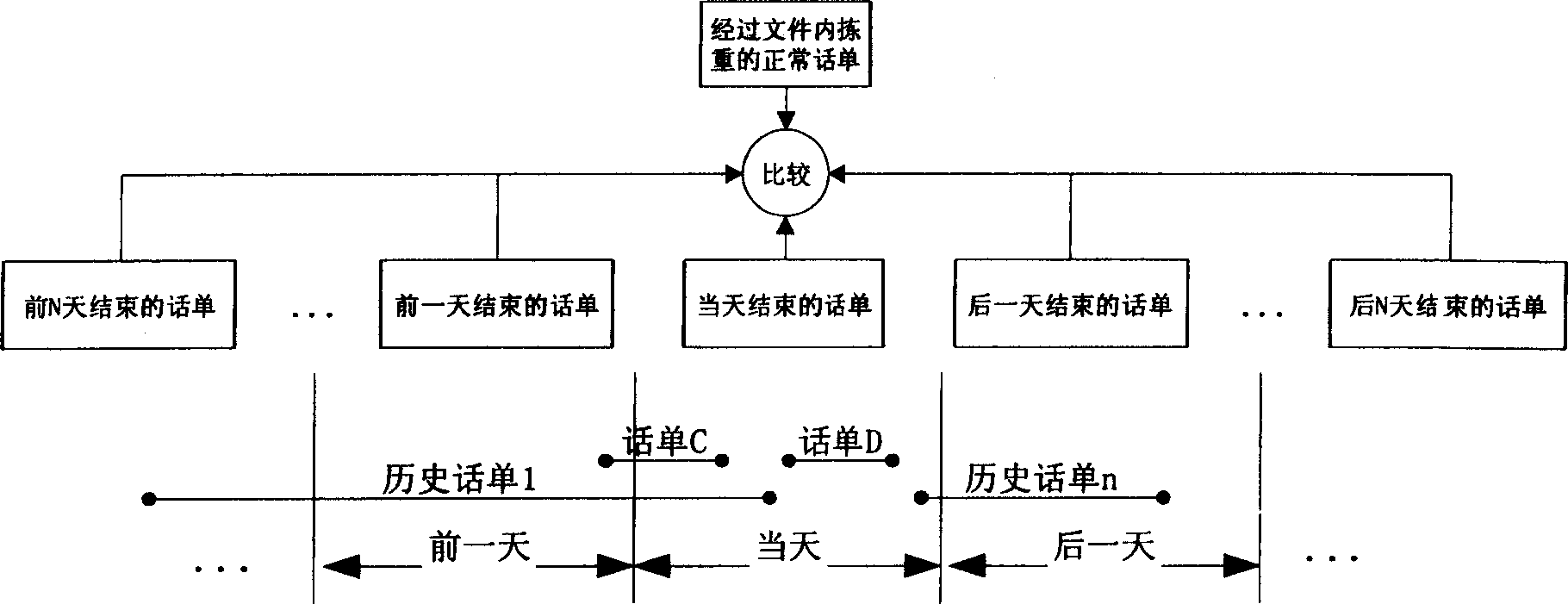

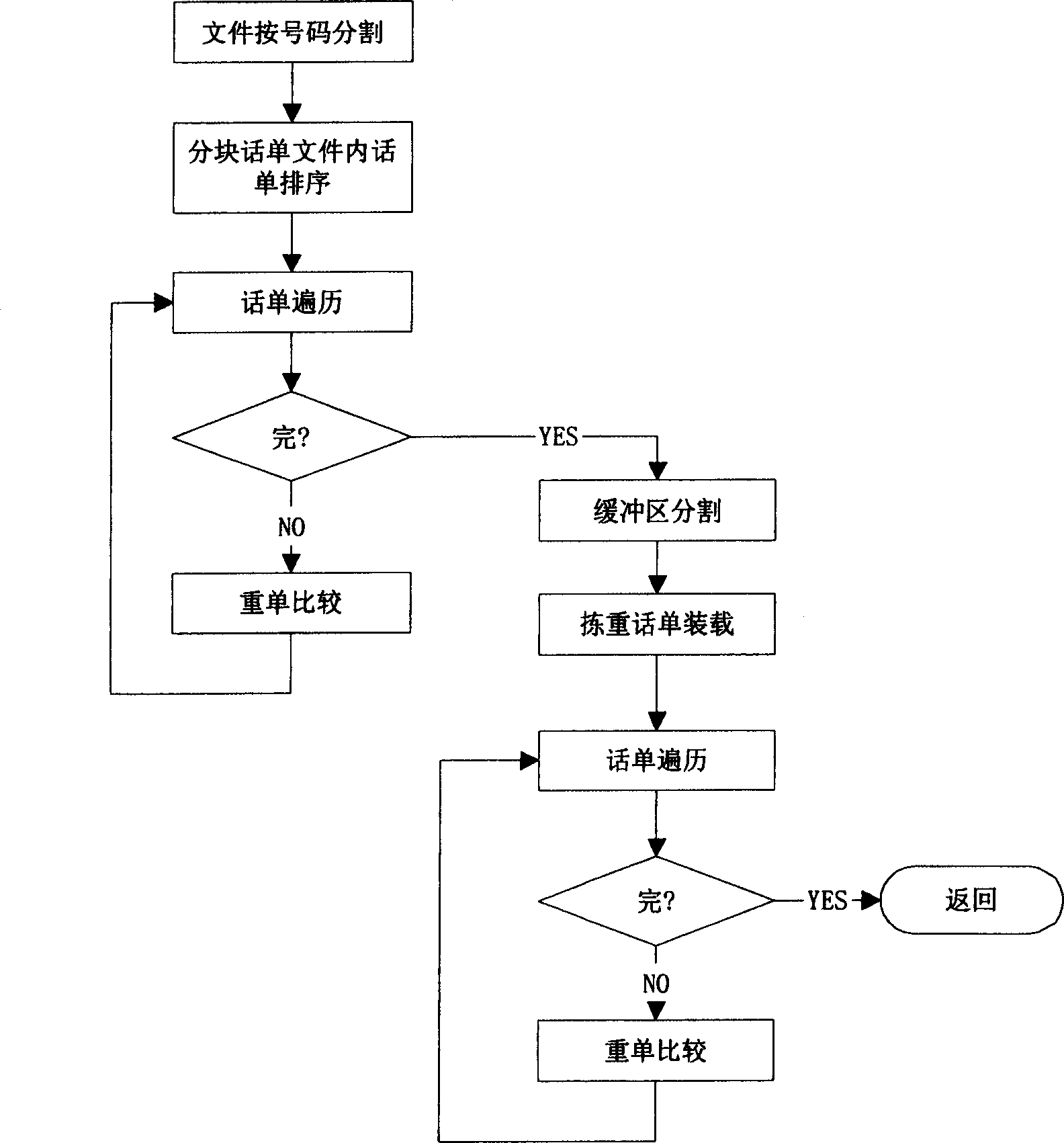

A call bill weight picking method

InactiveCN1525689AGuaranteed to maximizeImprove picking accuracyData switching networksStart timeComputer engineering

The invention is an emphasis picking method of call list in electron communication technology. The character lies in: divides the timing call list file into blocks, carries on emphasis picking in each call list file of correspondent block data, after the emphasis picking process, it generates call list blocks according to regulation, the call list of the generated call list blocks carries on emphasis picking between files in history call list, the processed call list blocks are written into the emphasis picking file, acquires the normal call list file, and the written files can be used as the history call list for next emphasis picking process; the timing call list file carries on block division to the files according to the regulation such as calling number, speaking start time, the finish time; the call list file of block data generate call list block according to the calling number and call list finished date, the invention can carry on emphasis picking in real-time and with high efficiency.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com