Multi-axis high-speed CNC lathe

A CNC lathe, high-speed technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, tool holders, etc., can solve the problems of low product processing accuracy, cumbersome and complicated processing process, and reduce production efficiency, so as to avoid excessive cantilever, Improve production efficiency and machining accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

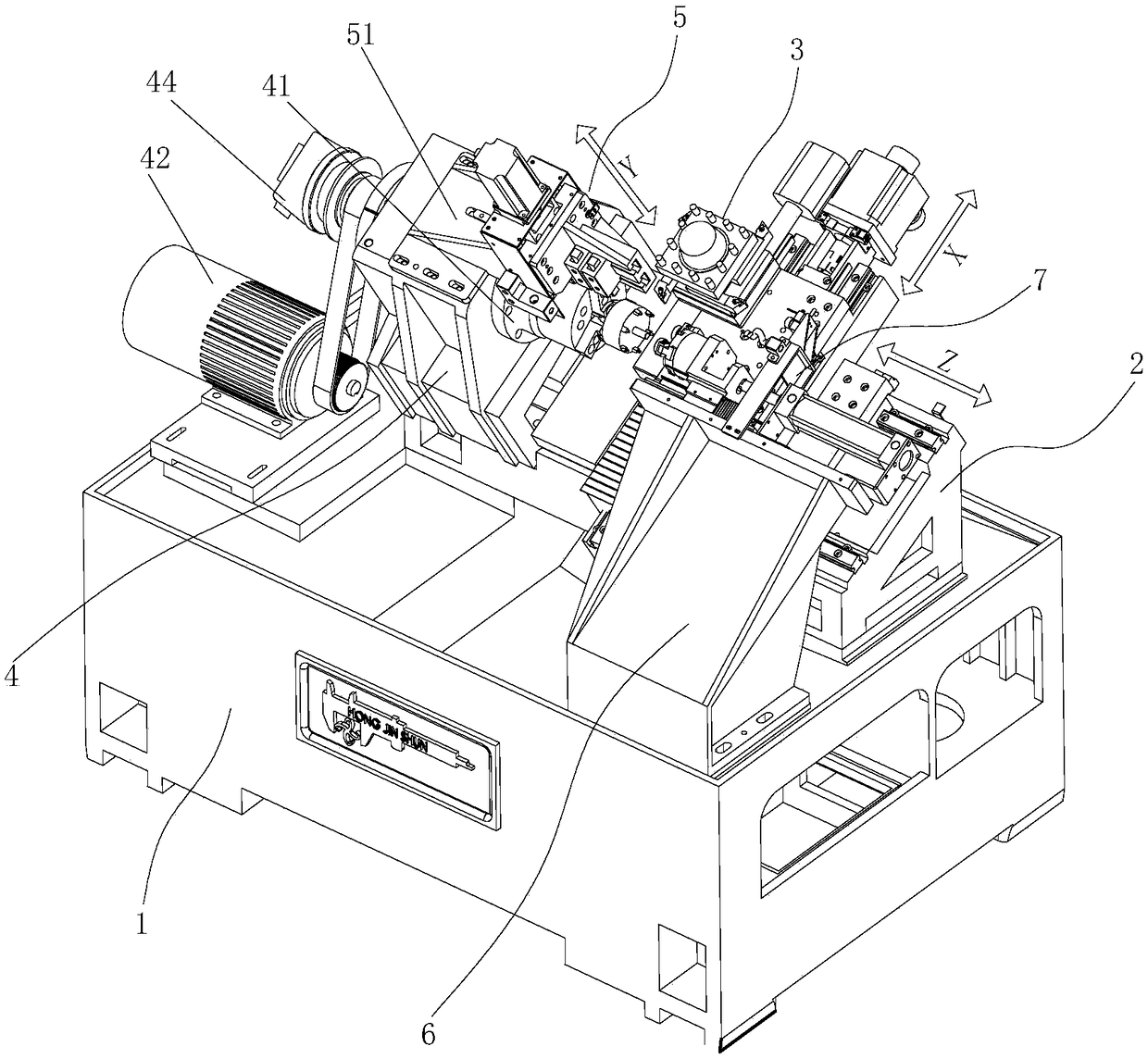

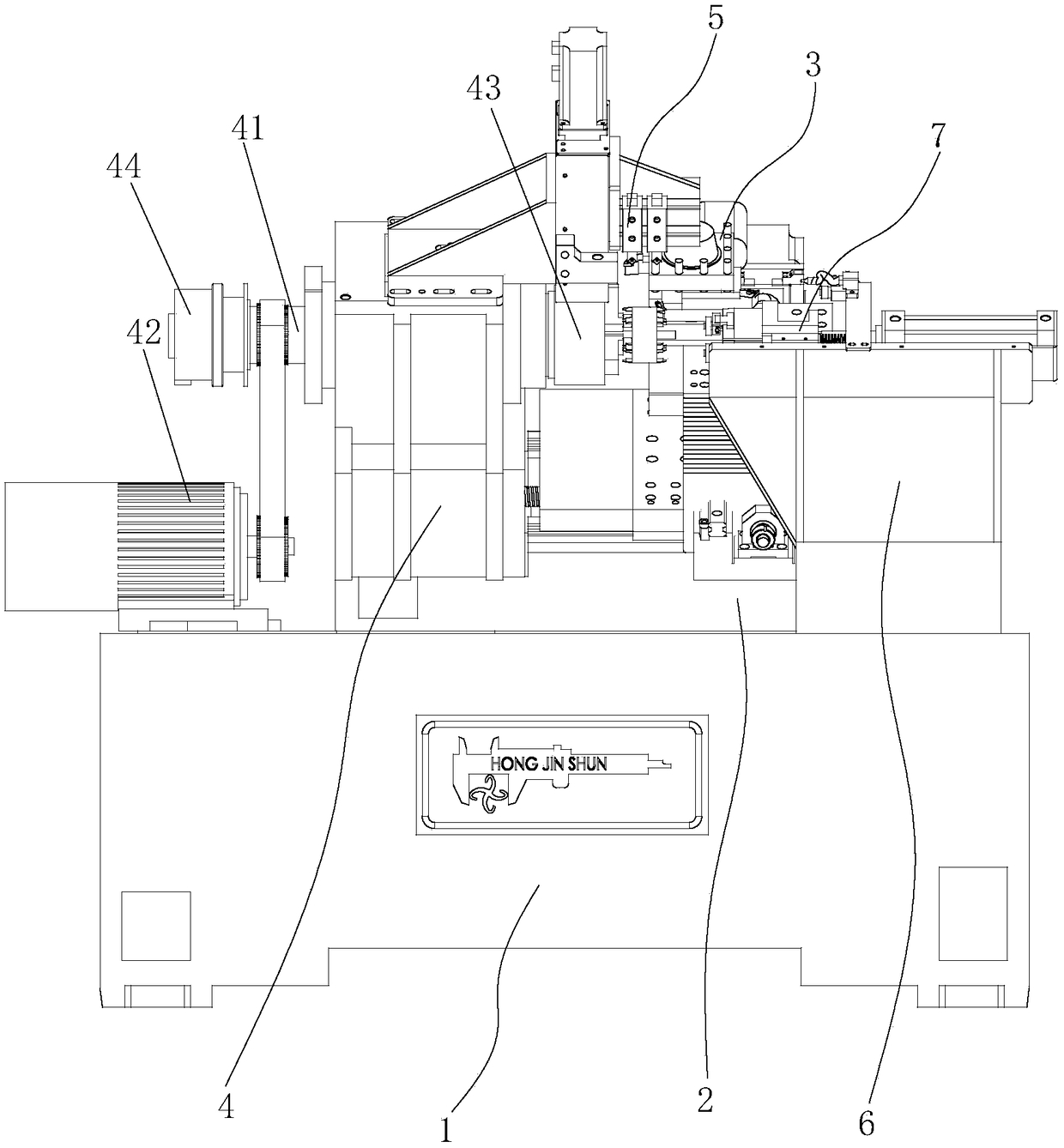

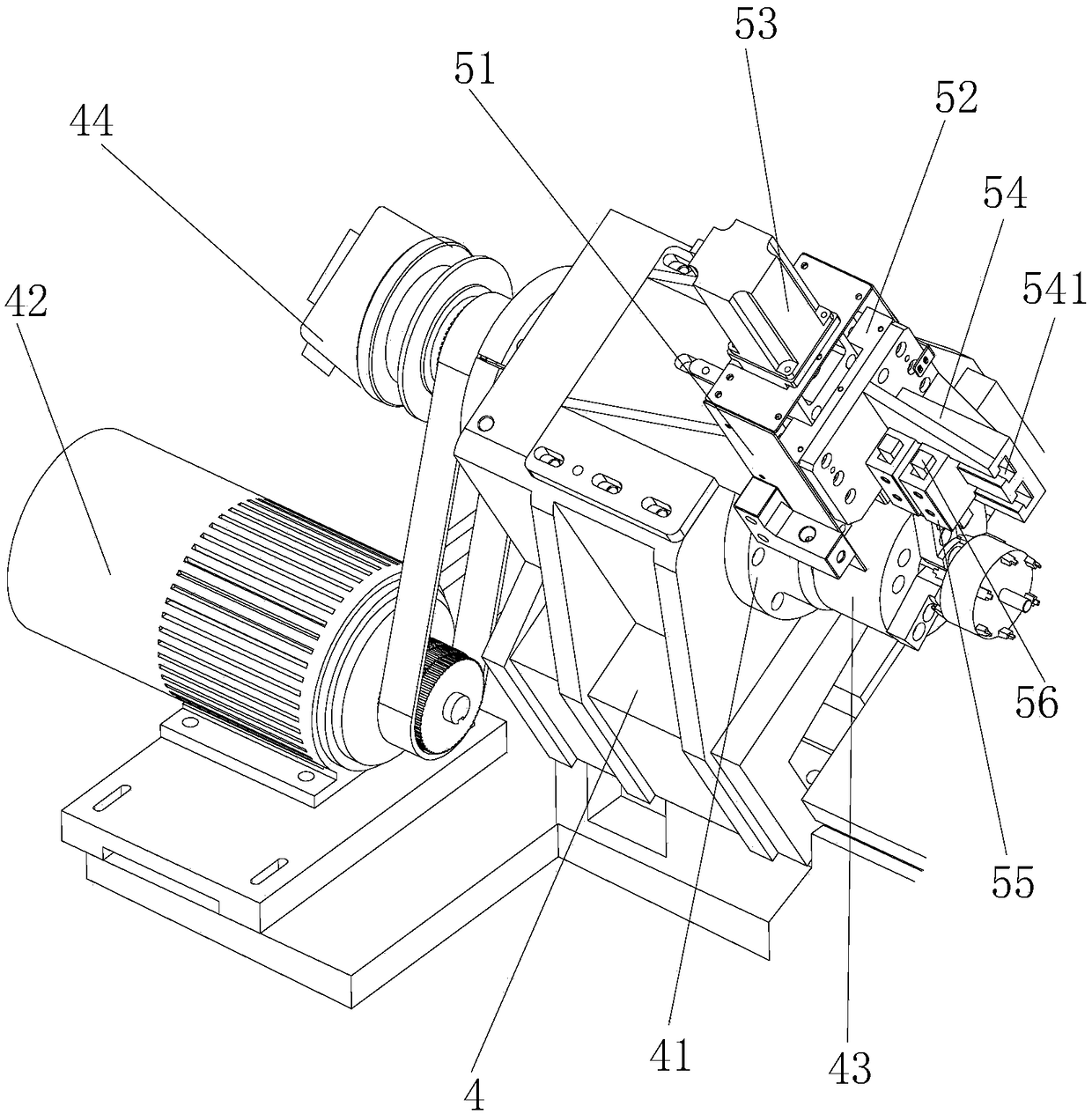

[0015] like Figure 1-Figure 5 As shown, what the present invention described is a kind of multi-axis high-speed numerical control lathe, and it comprises a slanted bed lathe body, and this slanted bed lathe body has a main frame 1 and a work surface and the main frame 1 is inclined setting (usually 60° or 45°) of the inclined bed assembly 2, the first slide table 21 (i.e. cross slide) and the first sliding table 21 (i.e. cross slide) which moves in the horizontal direction (i.e. Z axis) along its working surface are installed on the inclined bed assembly 2 The first slide table drive mechanism is equipped with a second slide table 22 (i.e. the X-axis carriage) and a second slide table drive mechanism 23 on the first slide table 21, and the second slide table is on the first slide table 21 along with The inclined bed assembly 2 moves in the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com