Automatic-regulating type hot-pressing head structure suitable for flip chip die bonding

A technology of automatic adjustment and thermal pressure head, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc. The effect of rate difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

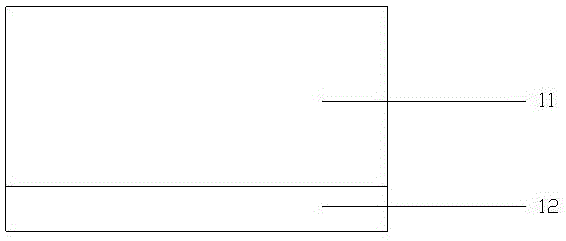

[0017] Example: The self-adjusting type thermal head structure suitable for flip-chip bonding provided by this embodiment has a structure such as figure 1 As shown, it includes the main body 11 of the existing thermal head and the elastic film 12 coated on its surface. The elastic film is made of a high-temperature-resistant high-elastic alloy and meets the following indicators: 1) The elastic modulus E is lower than 200GPa, The elastic modulus is used to reflect the elasticity of a material. If the elastic modulus is low, the elasticity is better; 2) The compressive strength is higher than 0.2GPa, and the high compressive strength can prevent the metal properties of the elastic film from being destroyed when the pressure exceeds the compressive strength. ; 3) The thickness is between 100um~10cm, and it has good elastic properties at 300K~1000K.

[0018] Highly elastic alloys and constant elastic alloys are the two main classes of elastic alloys. Due to the stress and strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com