Hot stamping bake toughening steel based on carbon partitioning principle and processing method thereof

A processing method and hot stamping technology, which is applied in the field of metallurgical materials and advanced high-strength steel for automobiles, can solve problems such as increased difficulty in process realization, and achieve the effects of improving development and technological progress, loose time, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

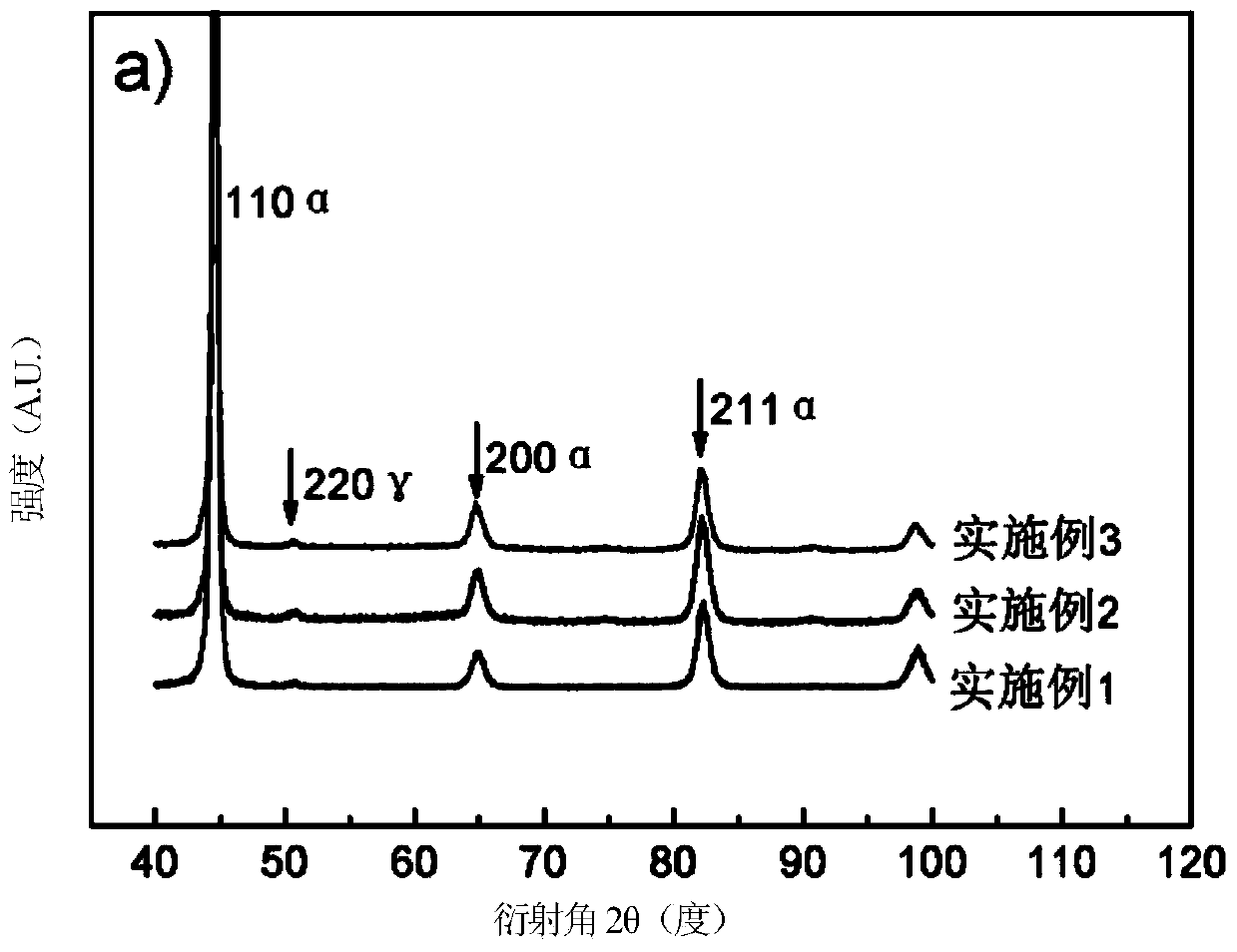

Embodiment 1

[0047] In this embodiment, the chemical composition (mass fraction) of the HS-BT steel sample is: 0.4% C, 0.32% Mn, 0.35% Cr, 0.5% Mo, 0.1% Ni, 0.8% Si, 0.2% Al, 0.003% B, 0.025% Ti, 0.5% Cu, 0.005% S, 0.008% P, the balance of Fe. The sheet was heated to 950°C for austenitization for 30 minutes, and then transferred to a press for hot stamping within 10 seconds. The pressure holding and quenching time in the mold was 60 seconds. After pressure holding and quenching, the mold was released and cooled to room temperature. Then the workpiece taken out is placed in a heat treatment furnace at a temperature of 150° C. and a holding time of 60 minutes. The average cooling rate of the hot stamping and pressure quenching process is 36°C / s. Measured by phase change dilatometer, the M of this steel s point at 237°C, M f The point is 80°C.

[0048] The test results of mechanical properties show that the tensile strength of the HS-BT steel is 2205MPa, the elongation is 9.3%, and the st...

Embodiment 2

[0051] In this embodiment, the chemical composition (mass fraction) of the HS-BT steel sample is: 0.35%C, 1.2%Mn, 0.56%Cr, 0.4%Mo, 0.7%Ni, 0.7%Si, 0.4%Al, 0.0028% B, 0.021% Ti, 1.5% Cu, 0.006% S, 0.003% P, the balance of Fe. The sheet is heated to 950°C for austenitization for 30 minutes, and then transferred to a press for hot stamping within 10 seconds. The holding and quenching time is 60 seconds. After holding and quenching, the mold is released and cooled to room temperature. Then the workpiece taken out is placed in a heat treatment furnace at a temperature of 200° C. and a holding time of 30 minutes. The average cooling rate of the hot stamping and pressure quenching process is 36°C / s. Measured by phase change dilatometer, the M of this steel s point at 230°C, M f The point is 50°C.

[0052] The test results of mechanical properties show that the tensile strength of the HS-BT steel is 2158MPa, the elongation is 10.4%, and the strength-plastic product is 22443MPa·% a...

Embodiment 3

[0055] In this embodiment, the chemical composition (mass fraction) of the HS-BT steel sample is: 0.3%C, 0.6%Mn, 0.5%Cr, 1.0%Mo, 0.39%Ni, 1.0%Si, 0.4%Al, 0.0036% B, 0.03% Ti, 1.0% Cu, 0.004% S, 0.005% P, the balance of Fe. The sheet is heated to 950°C for austenitization for 30 minutes, and then transferred to a press for hot stamping within 10 seconds. The holding and quenching time is 60 seconds. After holding and quenching, the mold is released and cooled to room temperature. Then the workpiece taken out is placed in a heat treatment furnace at a temperature of 250° C. and a holding time of 40 minutes. The average cooling rate of the hot stamping and pressure quenching process is 36°C / s. Measured by phase change dilatometer, the M of this steel s point at 232°C, M f The point is 58°C.

[0056] The test results of mechanical properties show that the tensile strength of the HS-BT steel is 2079MPa, the elongation is 9.8%, and the strength-plastic product is 20374MPa·% afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com