Circular rolling mechanism for steel ball

A steel ball and raceway technology, applied in the field of steel ball circulating rolling mechanism, can solve the problems of collision noise, high processing requirements and high manufacturing cost, and achieve the effect of reducing the axial gap of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The detailed structure, connection and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

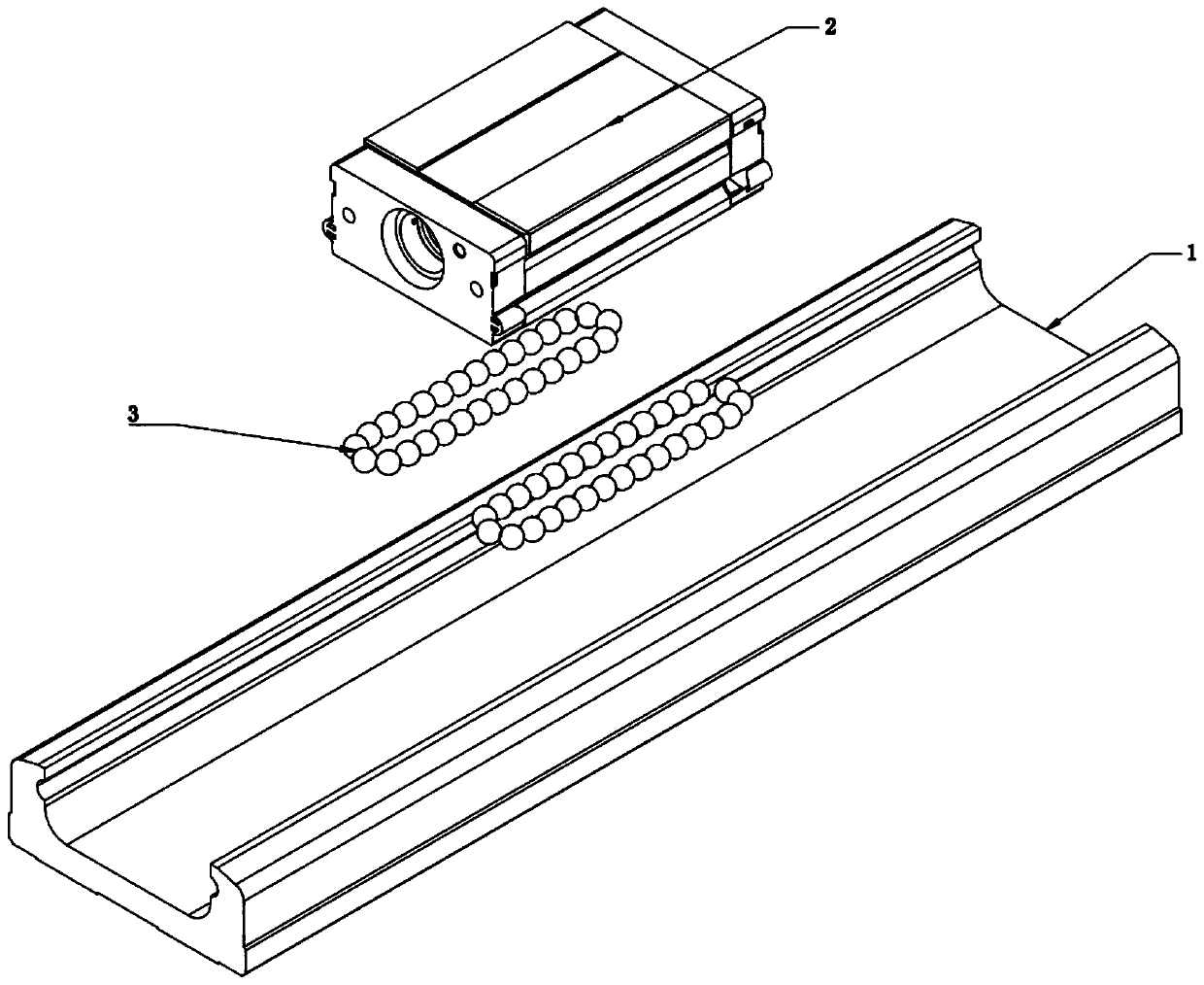

[0031] A steel ball circulation rolling mechanism, including a fixed part 1, a moving assembly 2 and a number of rolling steel balls 3,

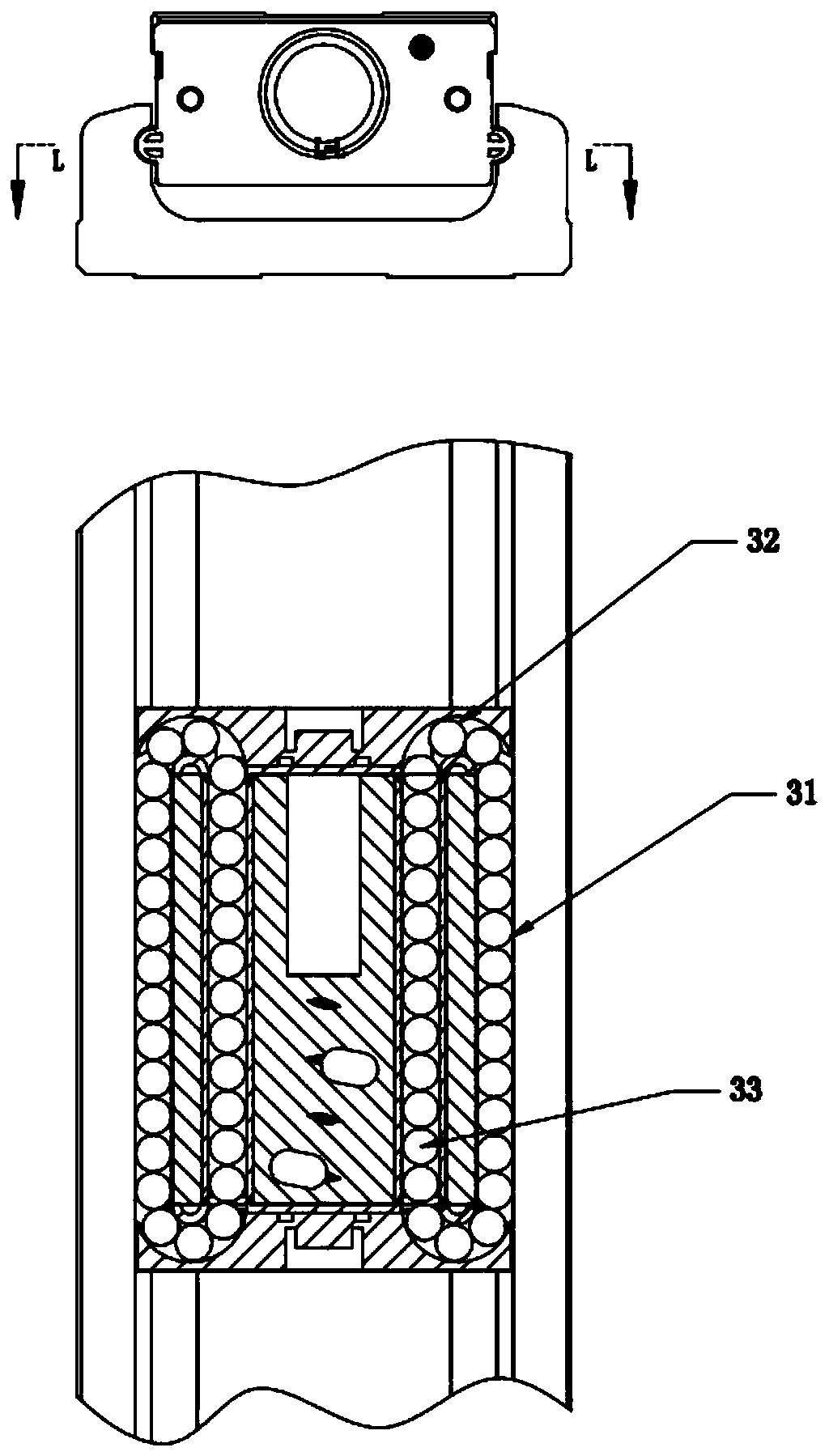

[0032] The rolling steel ball 3 is divided into load steel ball 31, reverse steel ball 32 and return steel ball 33 according to different positions;

[0033] The shape of the fixed part 1 is a U-groove structure, and both sides of the inner wall of the U-groove structure of the fixed part 1 are provided with fixed load raceways 11;

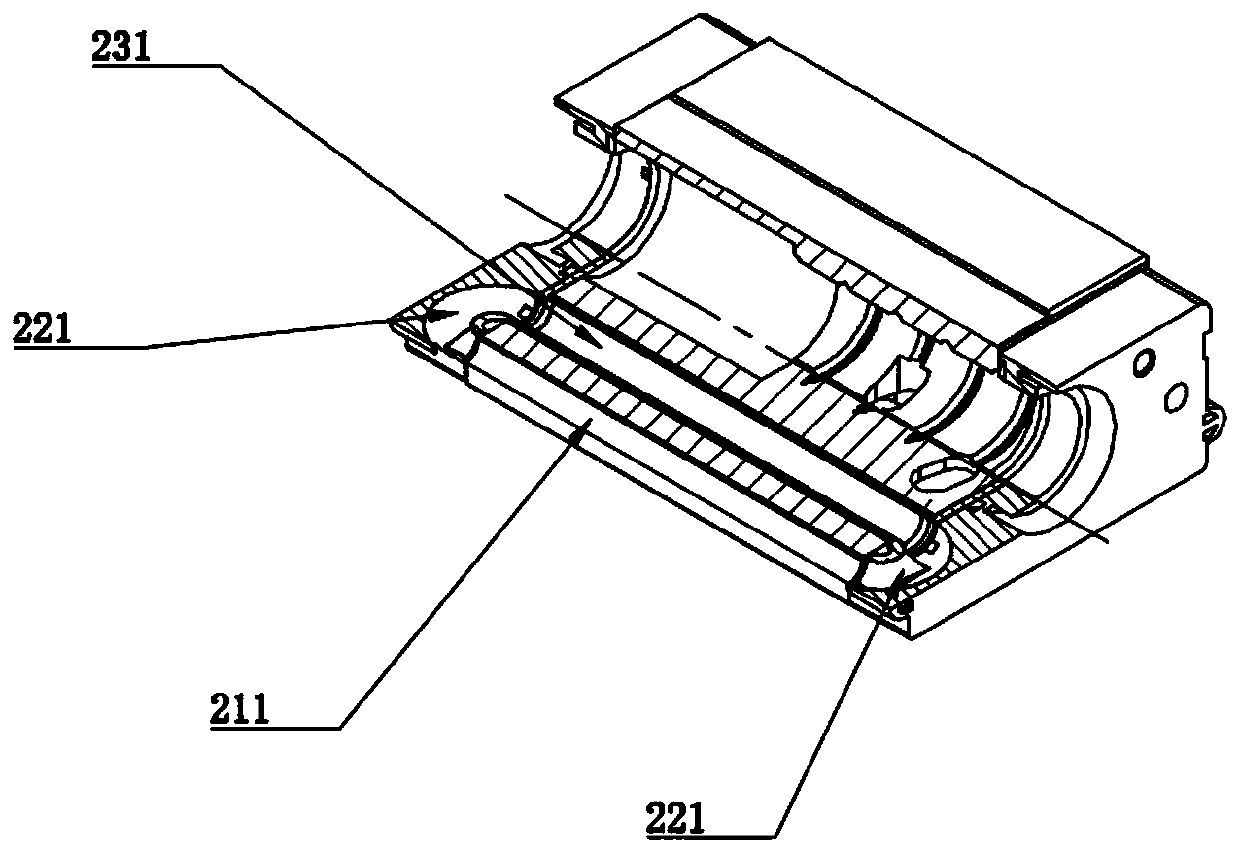

[0034] The moving assembly 2 includes a slider 21, a reverser 22, and a bead return pipe 23. The slider 21 has a rectangular structure, and two moving load raceways 211 are provided on both sides of the slider 21. The moving load raceway 211 is arranged opposite to the fixed load raceway 11, and there is a load steel ball 31 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com