Voltage detection method between non-contact poles for electrostatic induction micro electro discharge machining and circuit design thereof

A technology of inter-electrode voltage and electrostatic induction, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problem that the detection line cannot be directly connected, and achieve the effect of improving rotation accuracy and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

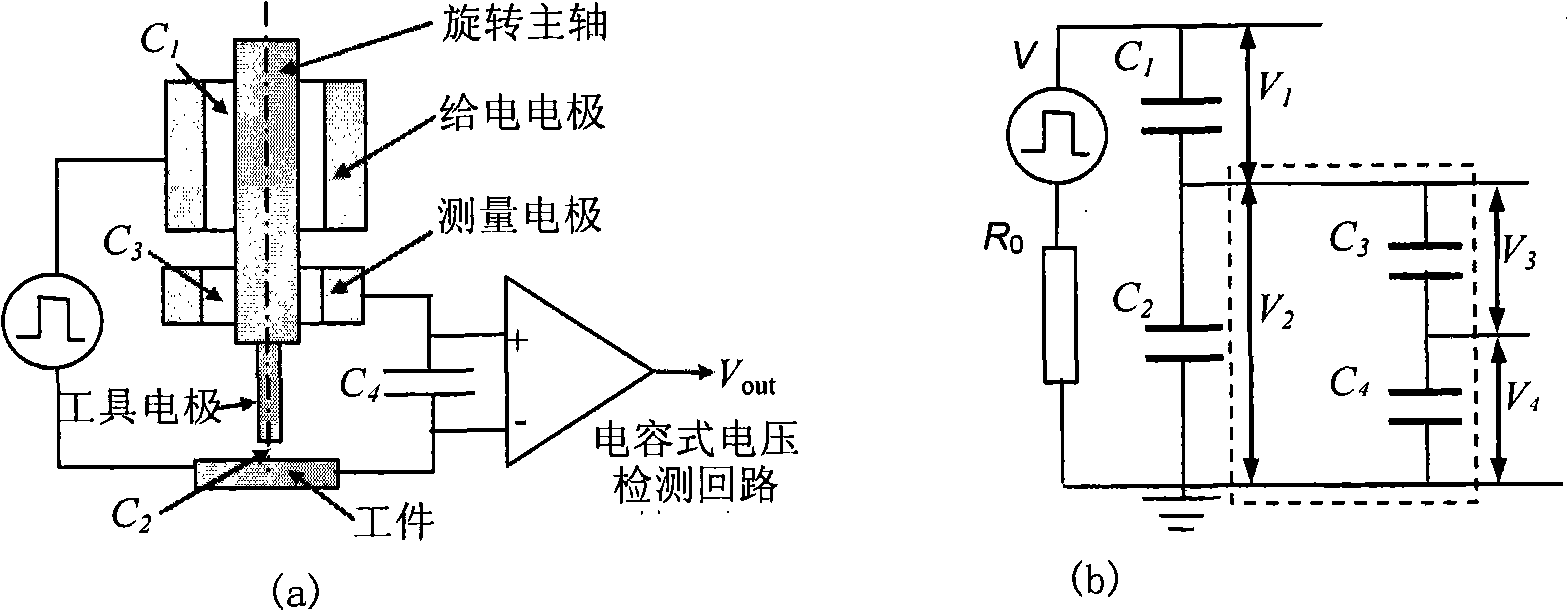

[0039] Figure 7 for adoption Figure 4 The inter-electrode voltage waveform and the output waveform of the detection circuit obtained when the bipolar discharge detection circuit shown in (a) is measured, Ch1 in the upper half of the figure is the inter-electrode voltage waveform, and Ch2 in the lower half is the output waveform of the detection circuit . Figure 7 (a) is the waveform when the circuit is open, Figure 7 (b) is the waveform during discharge. The experimental conditions are: C 1 =27pF,C 4 =82pF,R 1 = 50kΩ, R 2 =R 3 =R 4 =R 5 = 20kΩ, R 6 =R 7 = 10 kΩ. For the purpose of experimental verification and considering the convenience of the experiment, in the experiment C 3 Replace with a purchased capacitor, C 3 =27pF, this capacity is equivalent to the actual electrostatic capacitance formed between the measuring electrode and the tool electrode when using a non-contact measuring electrode, and the electrode diameter is The material is tungsten carbid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com