Cylinder sleeve workblank transfer device

A transfer device and cylinder liner technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of poor mechanical handling positioning accuracy and low degree of automation, and achieve the effects of high positioning accuracy, reduced labor intensity, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

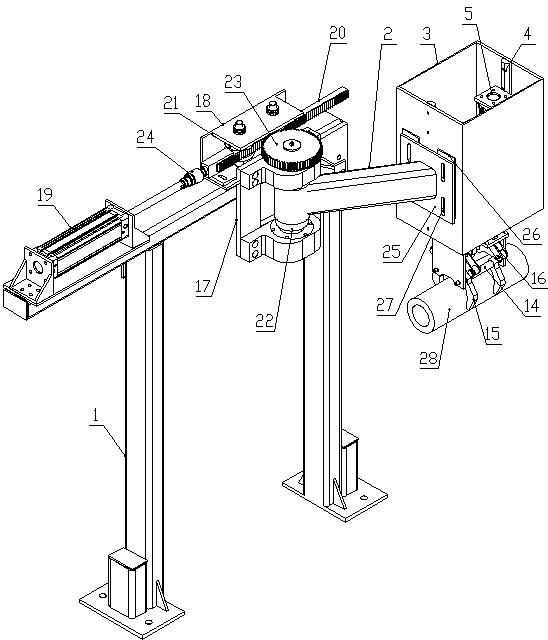

[0019] Such as figure 1 , figure 2 with image 3 As shown, the cylinder liner blank transfer device of the present invention includes a frame 1, on which a horizontal linear drive mechanism is installed, and the horizontal drive mechanism is connected with a vertical grabbing manipulator through a horizontal rotating arm 2.

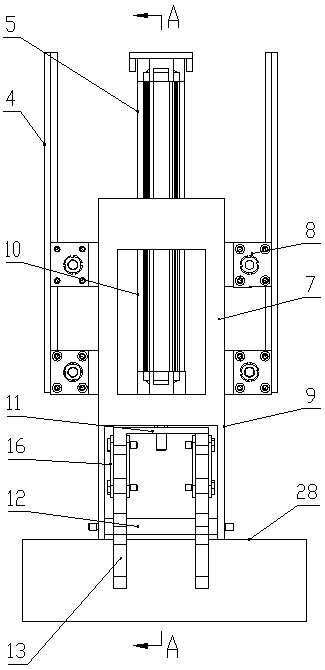

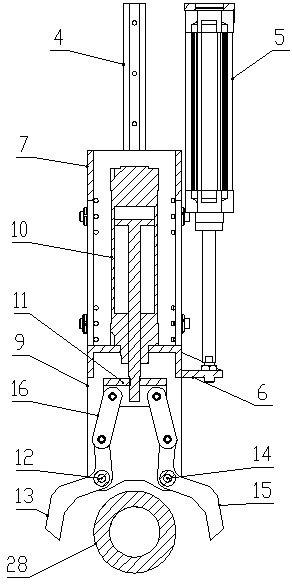

[0020] The vertical grabbing manipulator includes a square tube-shaped shell 3 vertically arranged, a guide rail 4 is vertically provided on the opposite inner walls of the shell 3, and a lifting cylinder 5 is vertically arranged on the other inner wall of the shell 3, and the lifting cylinder 5 The power drive end is connected to the inner shell 7 through a connecting piece 6, and the outer opposite sides of the inner shell 7 are respectively provided with rollers 8 rolling along a guide rail 4 on the same side. There are two rollers 8 on each side, and the lower end of the inner shell 7 is connected to There is a support frame 9, and the inner shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com