Adjustable special tool for outgoing line galloping vehicle

A special tool and adjustable technology, which is applied in the direction of overhead lines/cable equipment, cable laying equipment, etc., can solve the problems of easy rollover of operators, and achieve the effect of outstanding technical advantages, stable structure, and not easy to rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

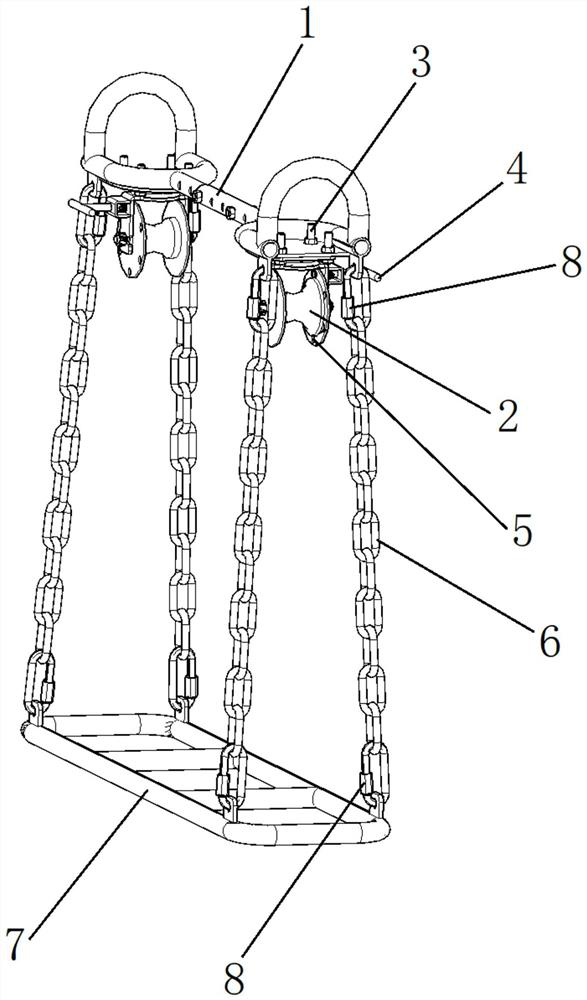

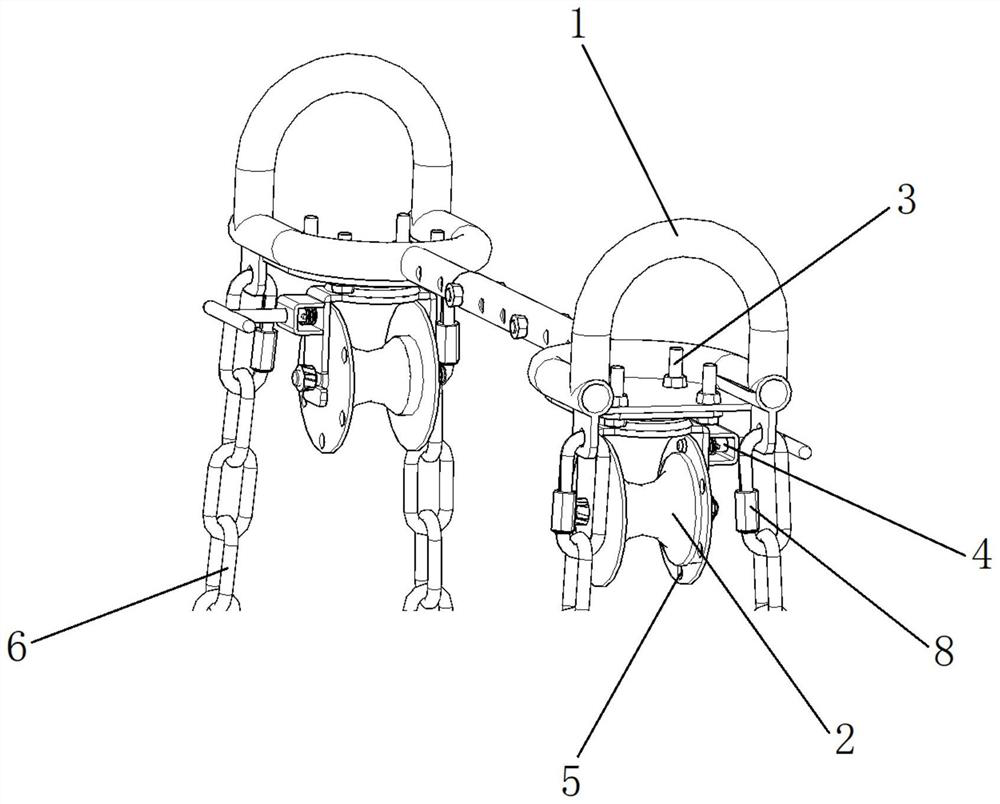

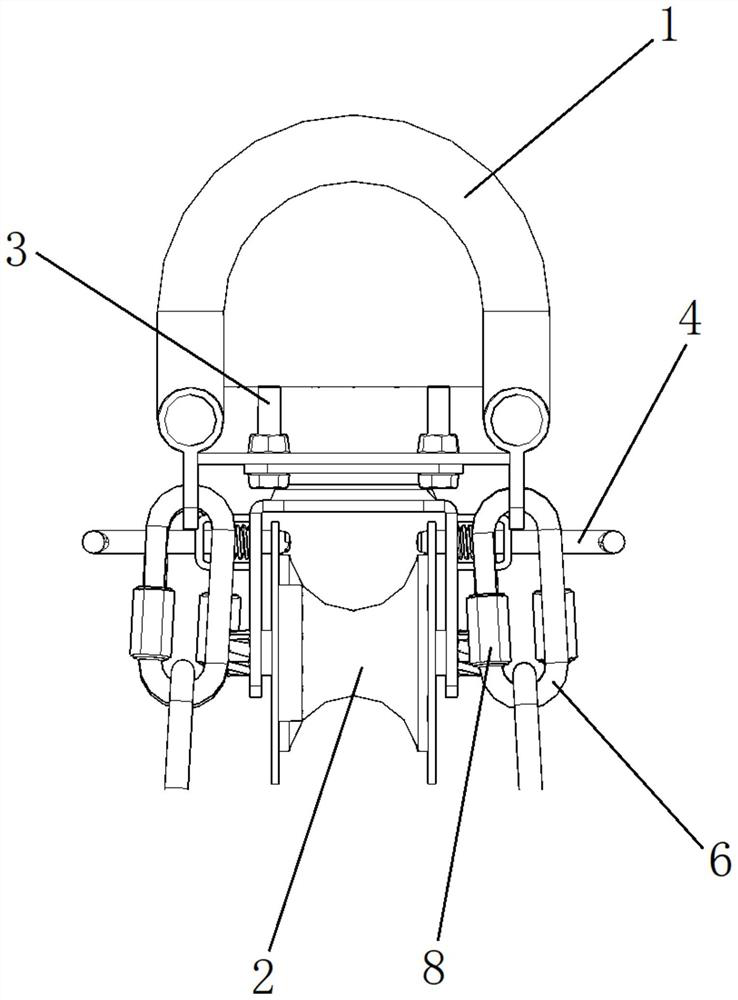

[0034] Adjustable outlet fly special tools, such as Figure 1~5 As shown, it includes a flying head fixing bracket 1, a pulley 2, a connecting bolt 3, a feed rod 4, a through hole 5, a cable 6, a block base 7, and a lock 8, wherein the support of the pulley 2 is fixed on the On the flying head fixed bracket 1, a feed rod 4 is provided on the support of the pulley 2, and several through holes 5 are arranged on the wheel disc of the pulley 2, and the feed rod 4 matches the through holes 5, and the flying head fixed bracket 1 is articulated with an iron cable 6, and the bottom end of the iron cable 6 is articulated with a block base 7, and the head end iron ring and the end iron ring of the iron cable 6 are respectively provided with a lock catch 8.

[0035] The structural features of this tool are as follows: the flying head fixed bracket 1 is the top basic structure of the present invention, which is used to play the role of foundation bearing; the pulley 2 should be of a type ...

Embodiment 2

[0037] Adjustable outlet fly special tools, such as Figure 1~5 As shown, it includes a flying head fixing bracket 1, a pulley 2, a connecting bolt 3, a feed rod 4, a through hole 5, a cable 6, a block base 7, and a lock 8, wherein the support of the pulley 2 is fixed on the On the flying head fixed bracket 1, a feed rod 4 is provided on the support of the pulley 2, and several through holes 5 are arranged on the wheel disc of the pulley 2, and the feed rod 4 matches the through holes 5, and the flying head fixed bracket 1 is articulated with an iron cable 6, and the bottom end of the iron cable 6 is articulated with a block base 7, and the head end iron ring and the end iron ring of the iron cable 6 are respectively provided with a lock catch 8. Wherein, the feed rod 4 is movably connected with the support of the pulley 2, and a spring is placed between the feed rod 4 and the support of the pulley 2. There are some lugs on the block base 7, and the lower ends of the lugs and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com