Chassis mechanism used for crawler-type backhoe loader and mounting and demounting of chassis mechanism

A backhoe loader and crawler type technology, applied in the field of chassis mechanism and its disassembly and assembly, can solve the problems of inconvenient transfer, complex structure, low disassembly and assembly efficiency, etc., and achieve a simple and fast installation method, broad application prospects, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail and completely below in conjunction with preferred embodiments and accompanying drawings.

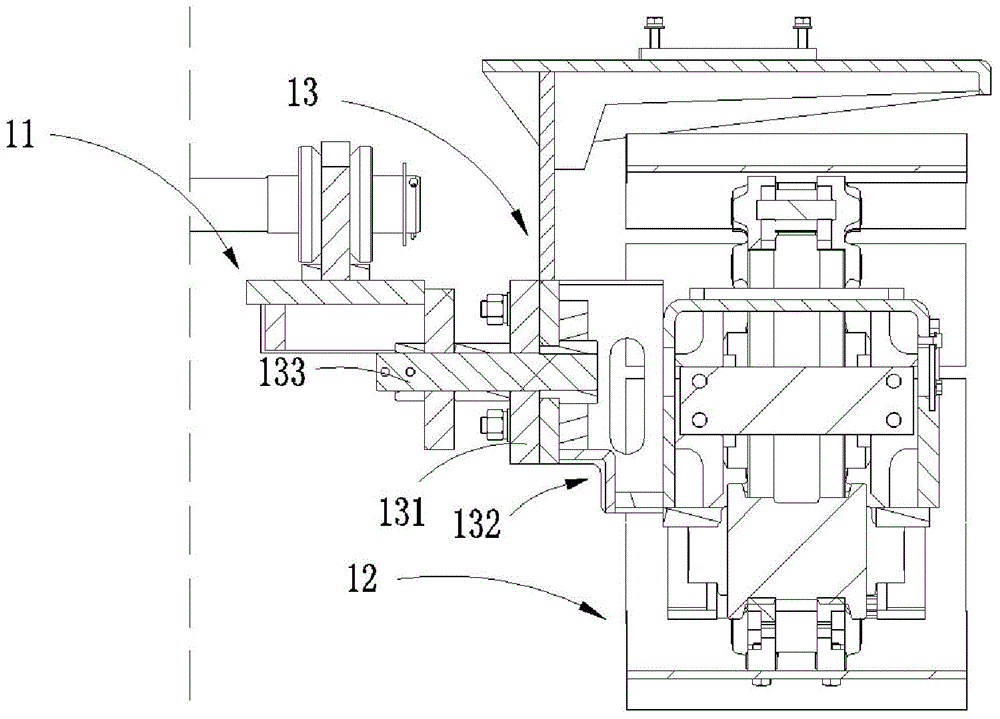

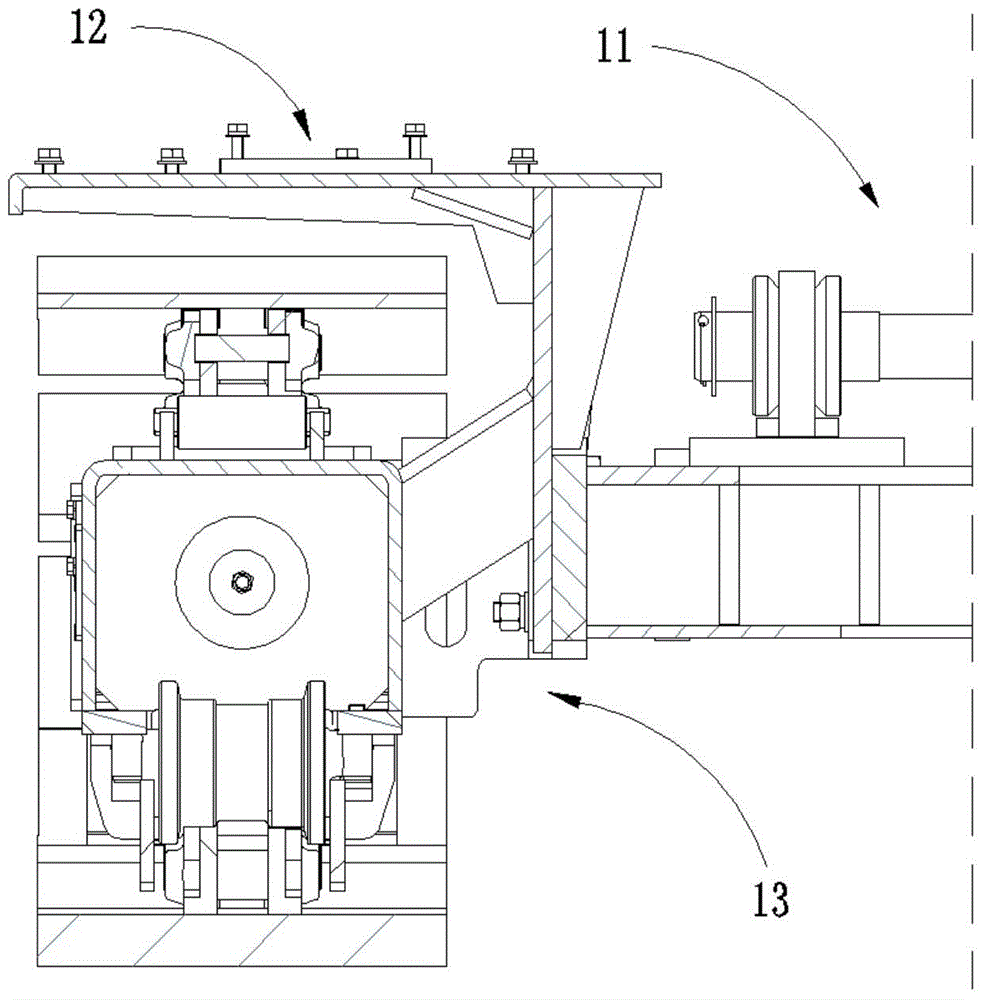

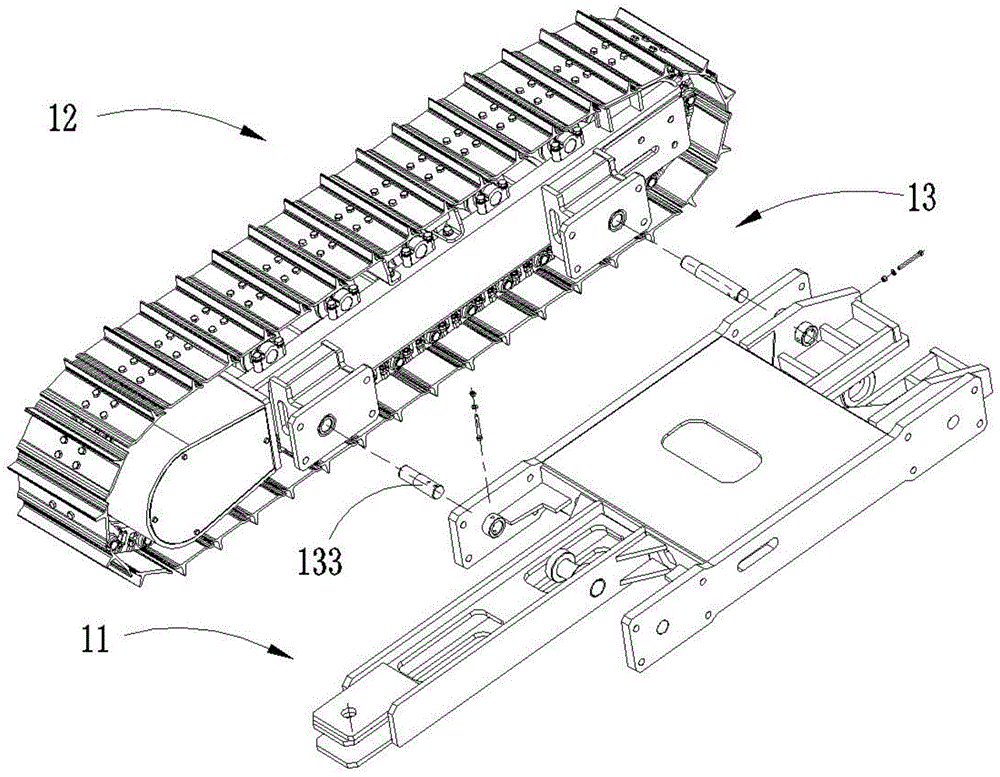

[0054] figure 1 and figure 2 The illustrated embodiment is a preferred embodiment of the chassis mechanism for the crawler backhoe loader provided by the present invention, such as figure 1 and figure 2 As shown, the chassis mechanism 1 includes a movably connected chassis support mechanism 11, a running mechanism 12, and a disassembly mechanism 13. The disassembly mechanism 13 connects the chassis support mechanism 11 and the two running mechanisms 12 to assemble the chassis mechanism 1. Specifically, The assembly and disassembly mechanism 13 comprises a connecting plate 131, two connecting seats 132 and two bearing shafts 133 which are movably connected. The opposite surfaces of the seat 132 are seamlessly fitted and movably connected, and the bearing shaft 133 runs through the bonding surface of the connecting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com