A prefabricated wall panel stacking rack

A technology of prefabricated wall panels and stacking racks, applied in storage devices, transportation and packaging, conveyors, etc., to achieve the effect of expanding the scope of application, reducing the risk of damage, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

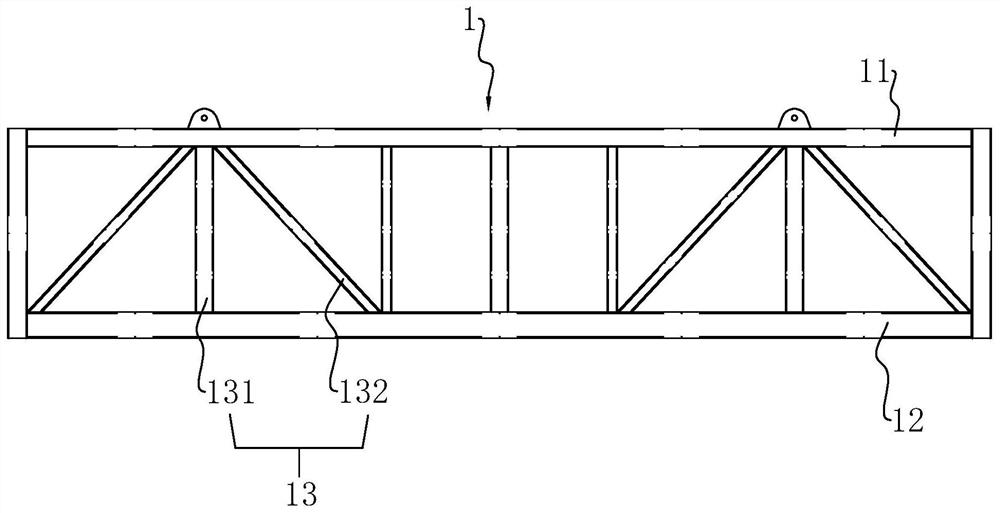

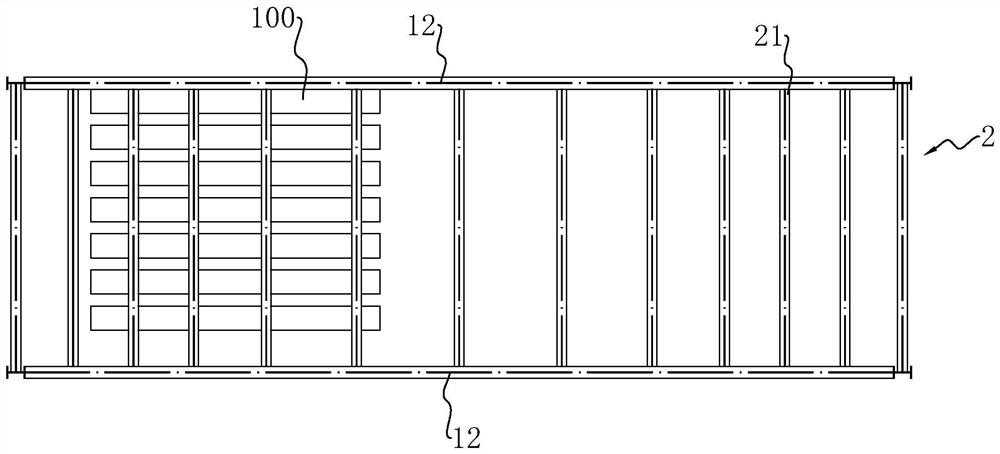

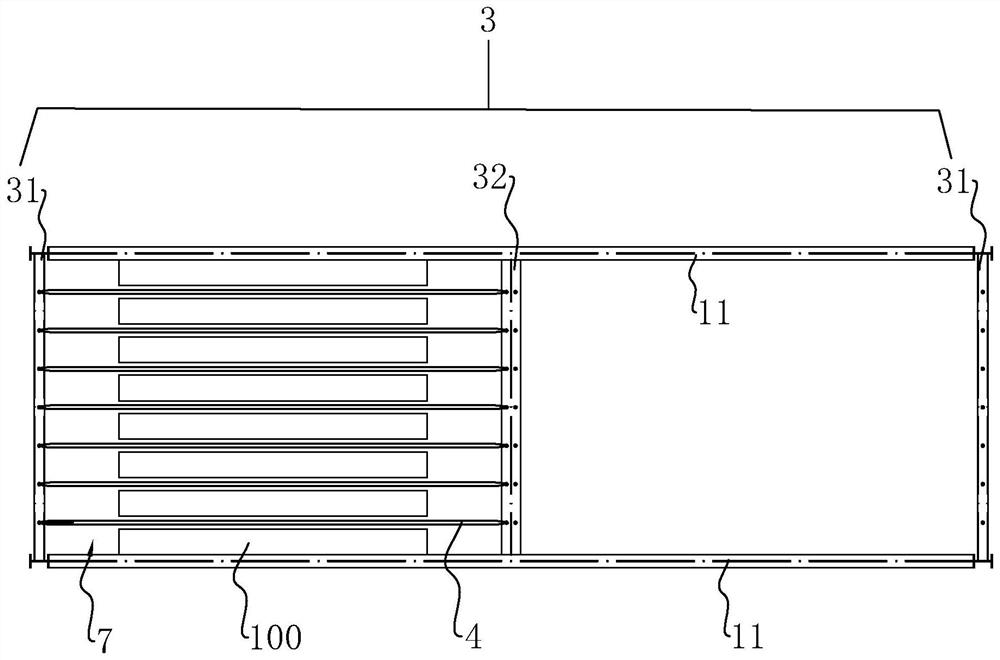

[0036] See attached Figure 1-2 , a kind of prefabricated wall panel stacking frame, comprises side frame 1, and side frame 1 is erected vertically, and is provided with two groups in parallel at intervals; Bottom supporting layer 2 is also arranged horizontally between side frame 1, and bottom supporting layer 2 width The two sides of the direction are respectively fixedly connected with adjacent two side frames 1 . In actual use, the staff can stack the prefabricated wall panels 100 on the bottom support layer 2 , and the left and right side frames 1 can limit the prefabricated wall panels 100 and improve the stability of the prefabricated wall panels 100 stacked.

[0037] as attached figure 1 As shown, the above-mentioned side frame 1 includes an upper chord 11 and a lower chord 12, the upper chord 11 and the lower chord 12 are made of I-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com