Round cross-shaped column base and manufacturing method thereof

A production method and technology of the cross, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of not being able to adapt to modern buildings, and achieve the effects of ingenious structural design, improved production efficiency, and strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

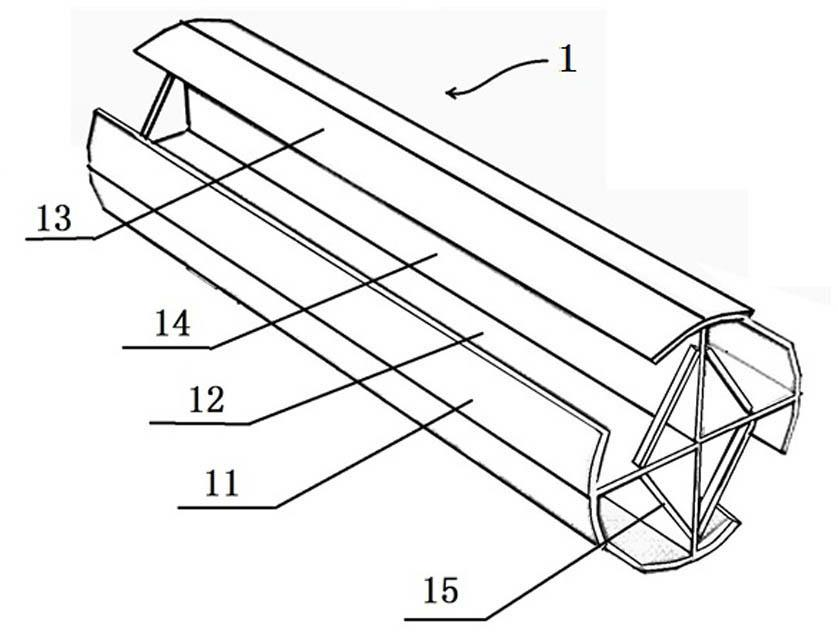

[0033] In this embodiment, the cross body 1 is composed of one H-shaped member and two T-row members. The H-shaped member is composed of two H-shaped arc-shaped panels 11 and a flat H-shaped web 12, and the two H-shaped arc-shaped panels 11 are respectively fixed on the two ends of the H-shaped web 12; the T-row members It consists of a plane T-row web 14 and a T-row arc-shaped panel 13, the T-row arc-shaped panel is fixed at one end of the T-row web; the T-row web 14 is vertically fixed to the H-shaped web 12 When fixing, the center line of the H-shaped web 12 coincides with the center line of the T-row web 14; the tooling plate 15 is fixed on the end of the T-row member and the H-shaped member, and the tooling plate 15 is connected with the T-row web, the H The web forms a triangle.

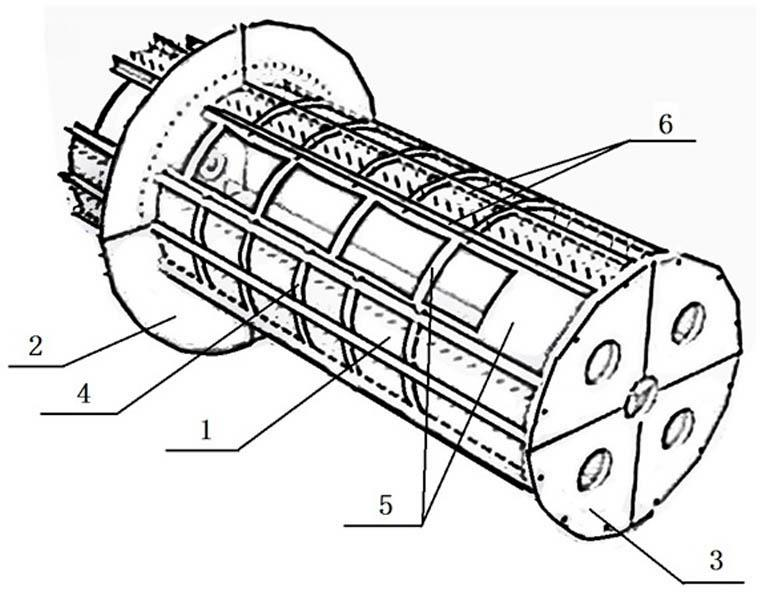

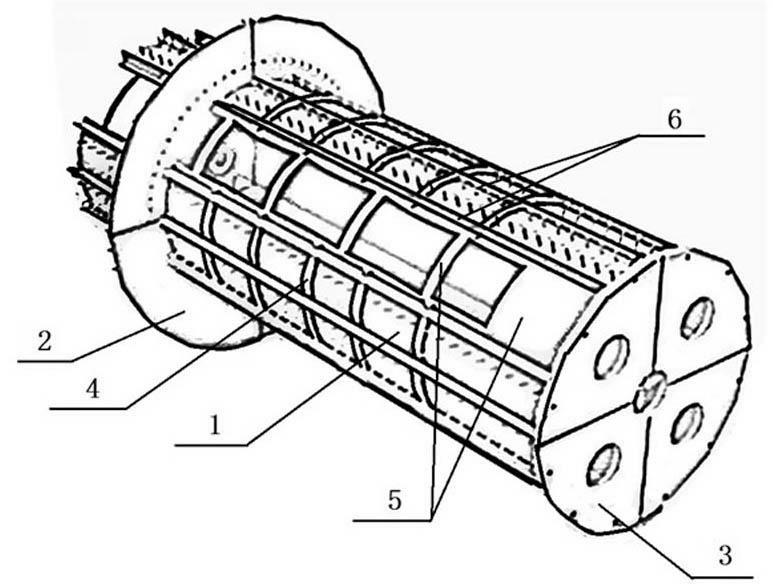

[0034] The connection relationship of each part in this embodiment is as follows: the outer ring plate 2 is fixed on the outside of the cross body 1; the column bottom plate 3 is fixed on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com