Loading-bearing filler strip and production method thereof

A production method and technology for gaskets, which are applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of rusted heavy object structure, heavy object damage, slurry leakage, etc., so as to improve the bearing capacity and wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

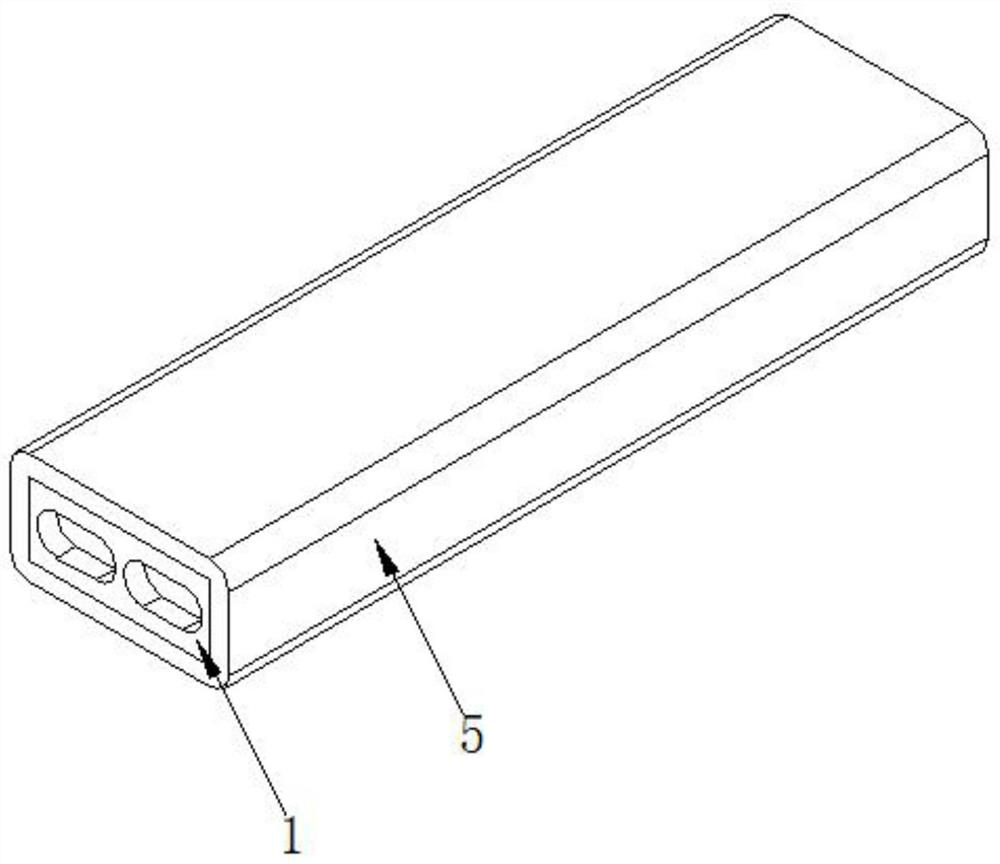

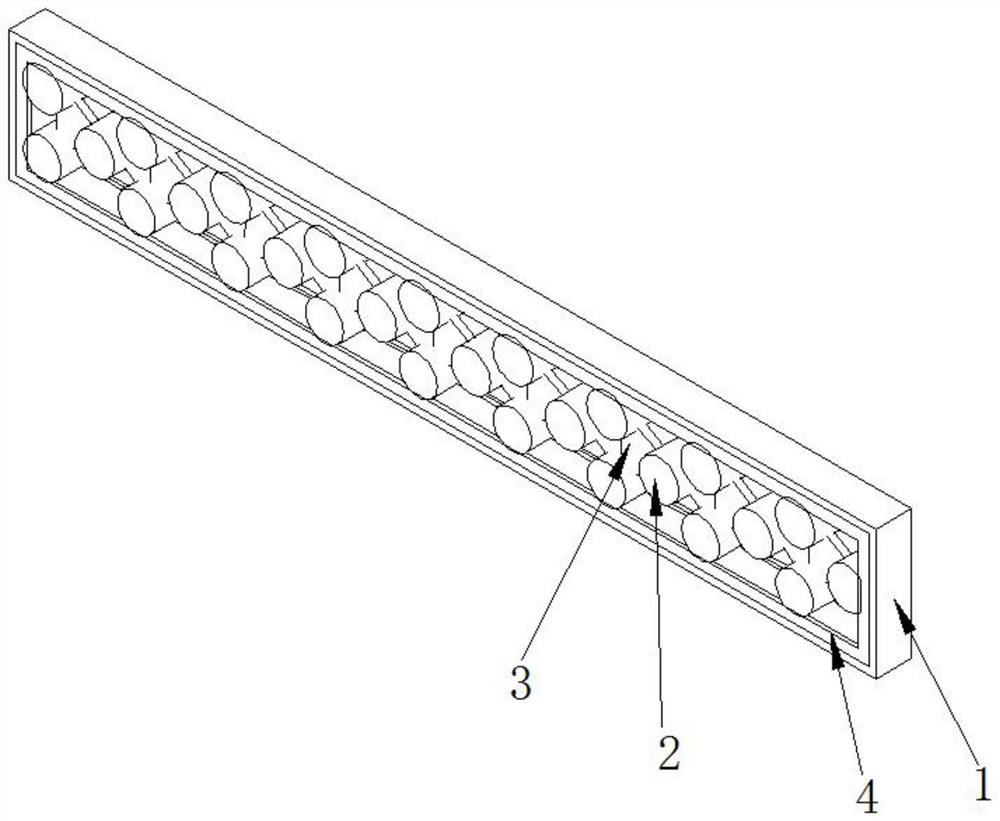

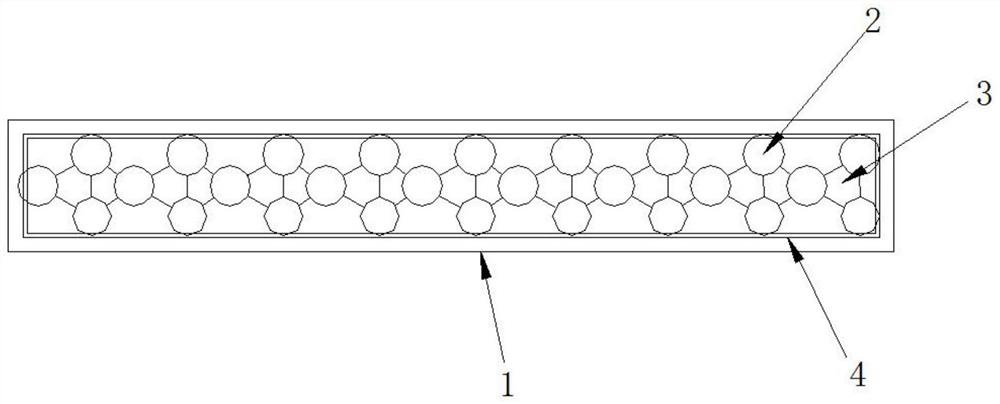

[0024] Refer Figure 1-3 A load bearing strip, including the inner core 1, the damper column 2 and the load-bearing plate 3, the load-bearing pallet 3 is a positive triangular structure, and the load-bearing pallet 3 is located between three damping columns 2, the load-bearing pallet 3 And the structure of the three damping columns 2 is distributed on the inner wall of the inner core 1, and the inner side of the inner core 1 is provided with a ride, and the inner wall of the slot is compressed, and the inner core 1 is made of polyurethane. Based, the damper column 2 is made of low-elastic rigid rubber, and the load-bearing pallet 3 is made of high strength aluminum alloy, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com