Steel-aluminum guide rail

A guide rail, steel and aluminum technology, applied in the field of guide rails, can solve the problems of poor load-bearing capacity and high cost of guide rails, and achieve the effect of improving load-bearing capacity and service life, low cost, and improving guide rail load-bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

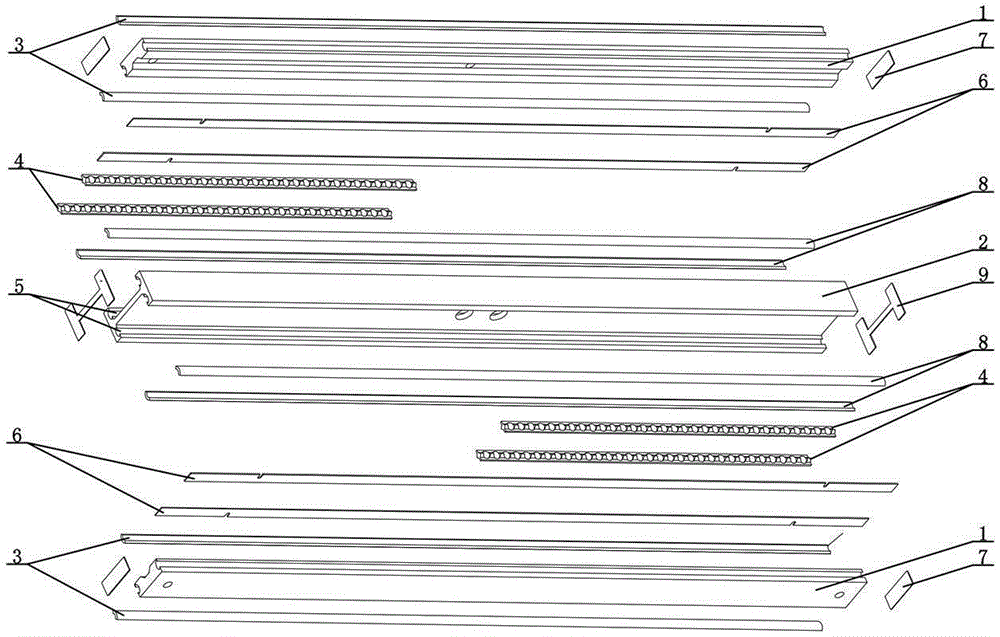

[0022] like figure 1 , figure 2 , image 3 As shown, a steel-aluminum guide rail includes movable load-bearing rails 2, two sets of slide rails 1, and sliding auxiliary parts 4. Grooves 5 are respectively arranged on both sides of the movable load-bearing rails 2, and the two sets of slide rails 1 The sliding auxiliary parts 4 are slidably arranged in the grooves 5 on both sides of the movable load-bearing rail 2 respectively. A first wear-resistant part 3 is arranged between the sliding auxiliary parts 4 and the slide rail 1. The sliding auxiliary parts 4 A second wear-resistant part 8 is arranged between the movable load-bearing rail 2, and the material of the movable load-bearing rail 2 and the slide rail 1 is aluminum alloy, and the first wear-resistant part 3 and the second wear-resistant part 8 are The materials are all steel, and the first wear-resistant part 3 and the second wear-resistant part 8 are strip-shaped and embedded in the slide rail 1 and the movable load...

Embodiment 2

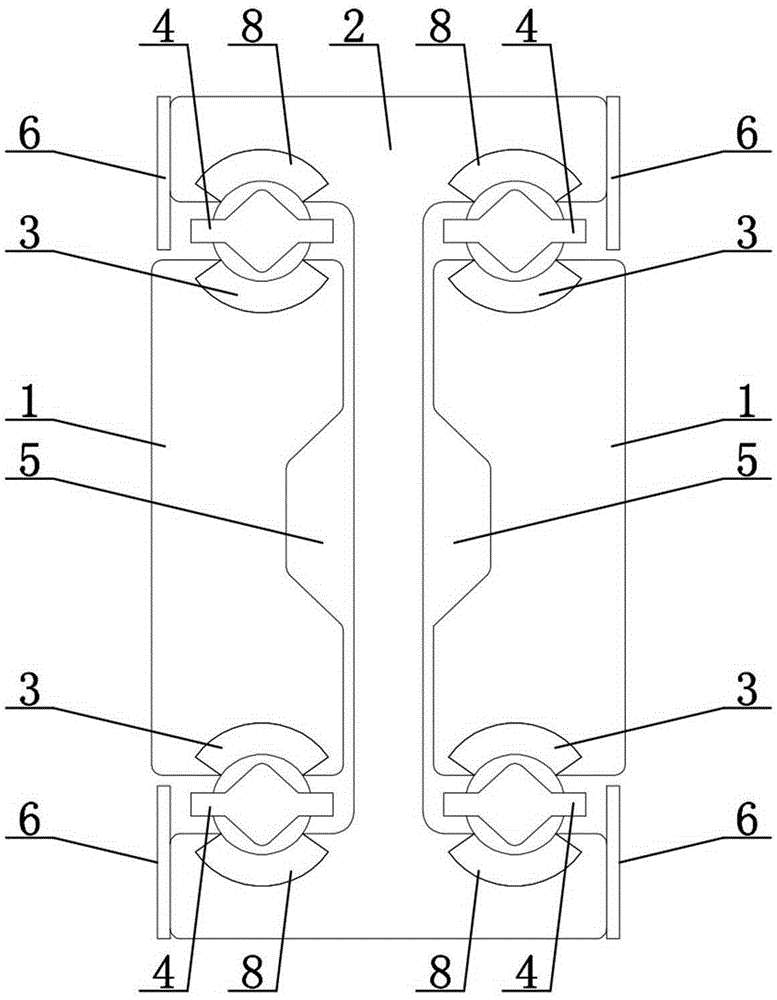

[0031] like Figure 4 , Figure 5 , Figure 6 As shown, a steel-aluminum guide rail includes movable load-bearing rails 2, two sets of slide rails 1, and sliding auxiliary parts 4. Grooves 5 are respectively arranged on both sides of the movable load-bearing rails 2, and the two sets of slide rails 1 The sliding auxiliary parts 4 are slidably arranged in the grooves 5 on both sides of the movable load-bearing rail 2 respectively. A first wear-resistant part 3 is arranged between the sliding auxiliary parts 4 and the slide rail 1. The sliding auxiliary parts 4 A second wear-resistant part 8 is arranged between the movable load-bearing rail 2, and the material of the movable load-bearing rail 2 and the slide rail 1 is aluminum alloy, and the first wear-resistant part 3 and the second wear-resistant part 8 are The material is all steel, the first wear-resistant part 3 and the second wear-resistant part 8 are in the shape of slide rails, and the second wear-resistant part 8 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com