Scissor fork type aerial work platform and scissor fork lifting assembly thereof

A scissor and assembly technology, applied in the field of scissor-type aerial work platforms and their scissor lift assemblies, can solve the problems of electric push rod damage, electric push rod does not have overload protection function, etc., to avoid equipment damage and safety incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following specific examples are only to explain the present invention, but not to limit the present invention. Those skilled in the art can make modifications without creative contribution to the present examples as needed after reading this specification, but as long as the rights of the present invention are used All claims are protected by patent law.

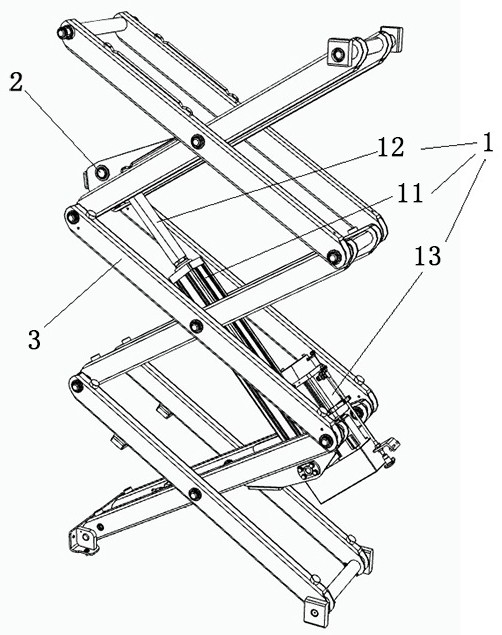

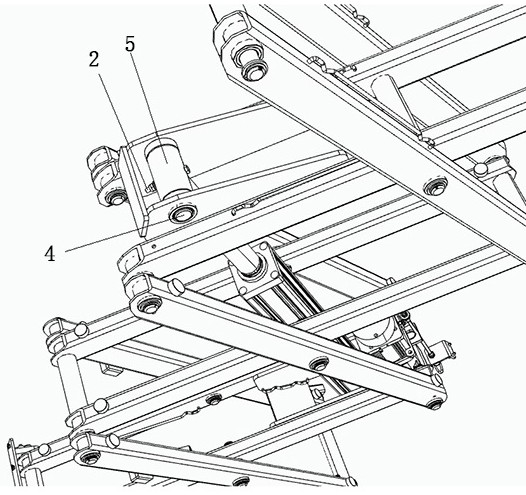

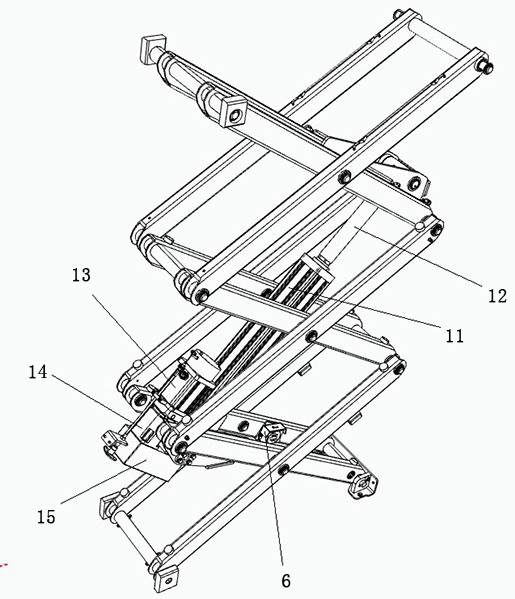

[0016] A scissor lifting assembly a of the present invention includes a scissor frame 3, a lifting mechanism 1 and a weighing mechanism 2. The scissors frame 3 is provided with a rotating connecting rod 4 transversely, and the rotating connecting rod 4 The scissor frame 3 can be rotated around its central axis relative to the scissor frame 3 , and the rotary link 4 and the scissor frame 3 are connected by a bearing to realize the rotation of the rotary link 4 . The lifting mechanism 1 adopts the form of an electric push rod 12 to avoid the use of a hydraulic system and achieve clean and efficient effects. Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com