Clamping plate capable of being stacked and preparing method for shell layer of clamping plate

A technology of shell layer and pallet, which is applied in the field of cargo transportation, can solve the problems of difficult cargo information management, unfavorable promotion and application in the field of cargo packaging, and small load-bearing capacity, so as to facilitate natural degradation and recycling, facilitate intelligent management, and load-bearing capacity enhanced effect

Pending Publication Date: 2017-09-22

东莞市腾卓美环保新材料科技有限公司

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, due to the shortage of wood, the cost of wooden pallets made of wood is getting higher and higher, resulting in higher and higher prices of wooden pallets. From the perspective of reducing costs and meeting environmental protection requirements, wooden pallets are not conducive to the delivery of goods Popularization and application in the field of packaging; traditional plastic pallets have defects in their strength, and from the perspective of environmental protection requirements, plastic pallets are not conducive to popularization and application in the field of goods packaging; metal pallets, due to their bulkiness and high price, are based on cost It is also not conducive to the promotion and application in the field of goods packaging

Although paper pallets have the advantages of environmental protection and light weight, they also have disadvantages such as poor mechanical properties, small load-bearing capacity and easy damage, which can easily cause huge losses to cargo transportation.

[0003] Generally speaking, the current existing pallets have the disadvantages of heavy weight and low load-bearing capacity; in addition, although the existing pallets facilitate the packaging and transportation of goods, they are inconvenient for their own transportation.

In addition, the existing pallets still have the disadvantages of being inconvenient for the information management of the pallet itself and the goods, not easy to degrade, and easy to cause environmental pollution.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0058]

[0059] The middle filling layer is prepared from the following components by mass:

[0060]

[0061]

Embodiment 2

[0063]

[0064] The middle filling layer is prepared from the following components by mass:

[0065]

Embodiment 3

[0067]

[0068]

[0069] The middle filling layer is prepared from the following components by mass:

[0070]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Login to View More

Abstract

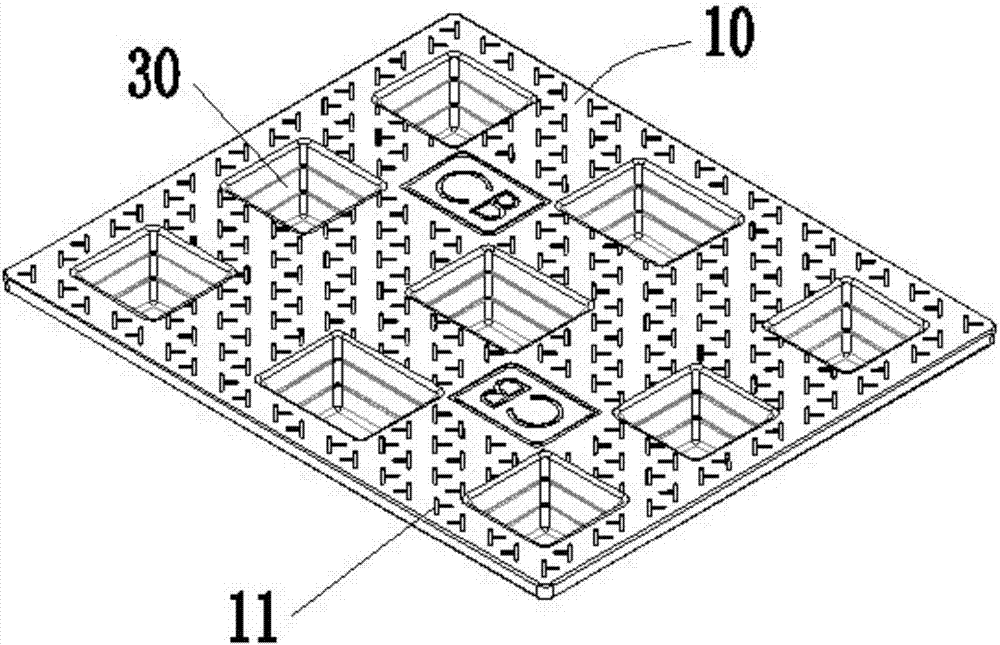

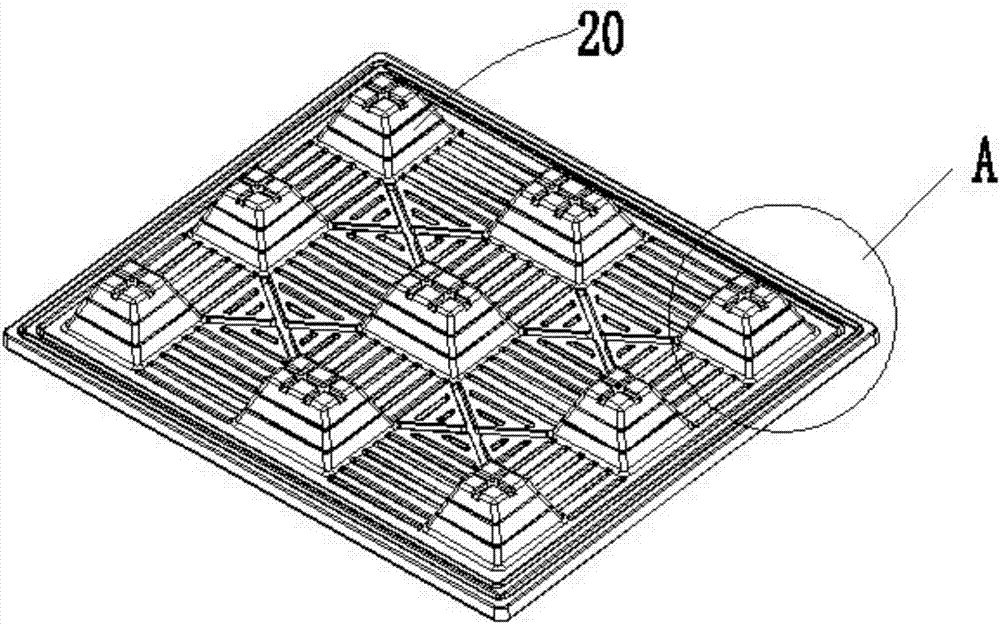

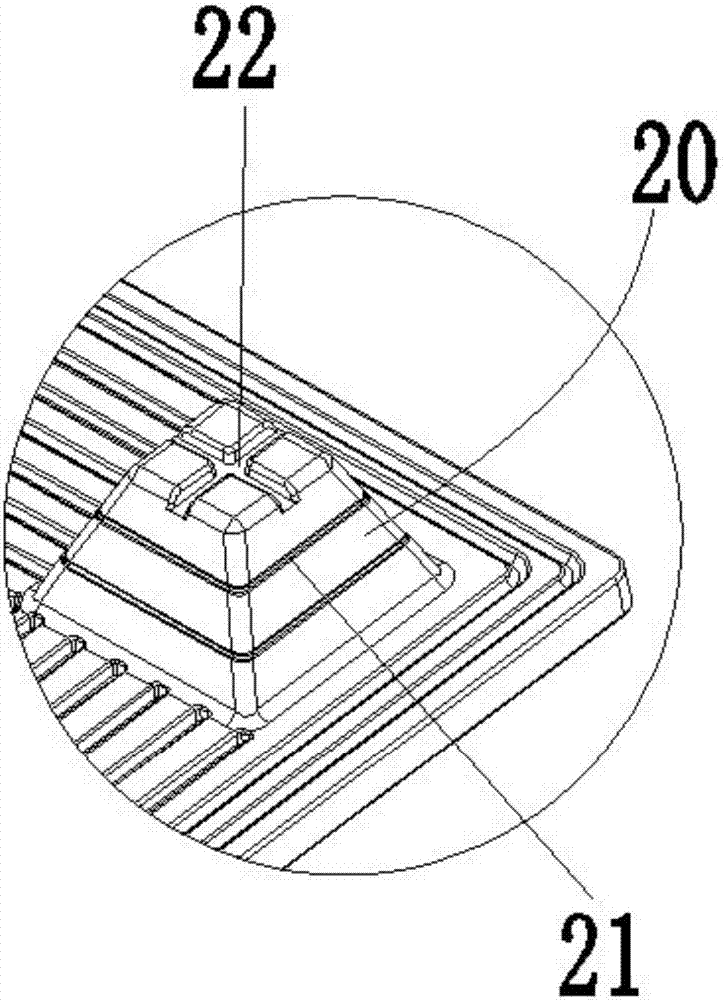

The invention discloses a clamping plate capable of being stacked. The clamping plate comprises a bearing plate and multiple supporting feet arranged at the bottom of the bearing plate. The supporting feet are of hollow structures, openings are formed in the sides, located on the top face of the bearing plate, of the supporting feet, and one or more stressed telescopic grooves are formed in the periphery of each supporting foot in a circular manner. Stripes for strengthening the bearing force of the supporting feet are arranged at the bottoms of the supporting feet, and stripes used for strengthening the bearing force of the bearing plate are arranged on the top face and / or the bottom face of the bearing plate. By means of the clamping plate, due to the fact that the supporting feet are arranged to be of the hollow structures with the top openings, the weight of the clamping plate can be effectively reduced, multiple clamping plates can also be stacked conveniently, and due to the fact that the stressed telescopic grooves are formed in the peripheries of the supporting feet in the circular manner and the stripes capable of resisting pressure and conducting buffering are arranged on the top face and the bottom face of the bearing plate, the bearing capability of the clamping plate can be greatly improved.

Description

technical field [0001] The invention relates to the technical field of cargo transportation, in particular to a method for preparing a stackable environment-friendly pallet and an outer shell layer thereof. Background technique [0002] Pallets, also called pallets, are important carriers for packaging large goods. They not only require a relatively high load-bearing capacity, but also require their own light weight to help reduce transportation costs. Traditional pallets include wooden pallets, plastic pallets, metal pallets and paper pallets. At present, due to the shortage of wood, the cost of wooden pallets made of wood is getting higher and higher, resulting in higher and higher prices of wooden pallets. From the perspective of reducing costs and meeting environmental protection requirements, wooden pallets are not conducive to the delivery of goods Popularization and application in the field of packaging; traditional plastic pallets have defects in their strength, and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65D19/24B65D19/40C08L23/08C08L97/02C08L101/00C08K13/02C08K3/36C08L75/08C08L83/04B29D7/01B29C45/00B29K31/00B29K511/00

CPCB65D19/0051B65D19/40C08L23/0853C08L75/08B29C45/0001B29D7/01B65D2519/00835B65D2519/0094B65D2519/00039B65D2519/00074C08L2205/03C08L2205/08C08L2205/16B29K2511/00B29K2031/04C08L97/02C08L101/00C08K13/02C08K3/36C08L83/04

Inventor 梁青林

Owner 东莞市腾卓美环保新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com