Light-burned dolomite light-weight wall partition board

A light-weight partition board, light-burning dolomite technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of consuming magnesite resources, difficult to popularize and apply, etc. The effect of improving, expanding the scope of application and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a light-burned dolomite lightweight partition wall board and its manufacture method, it comprises the following steps successively:

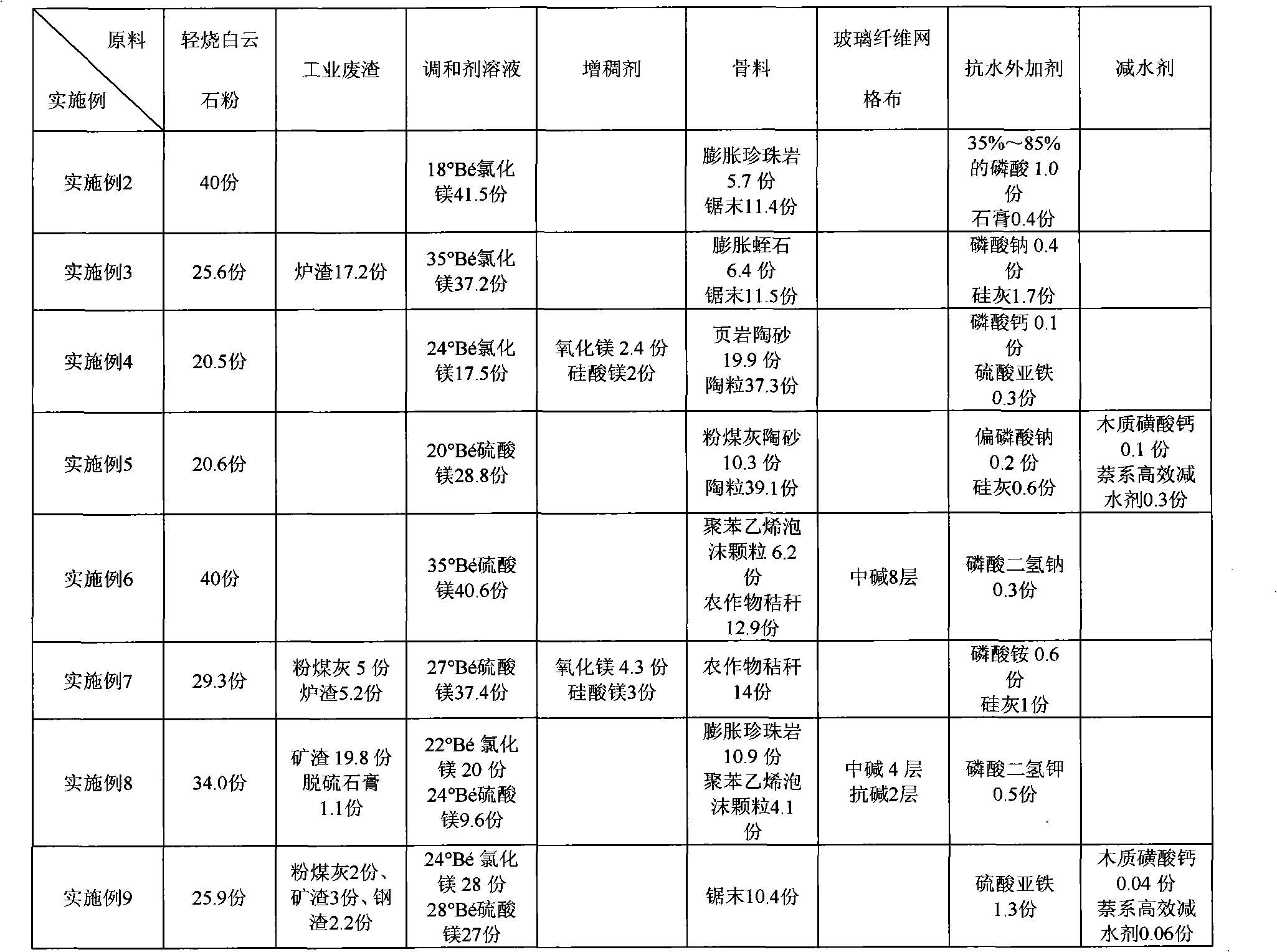

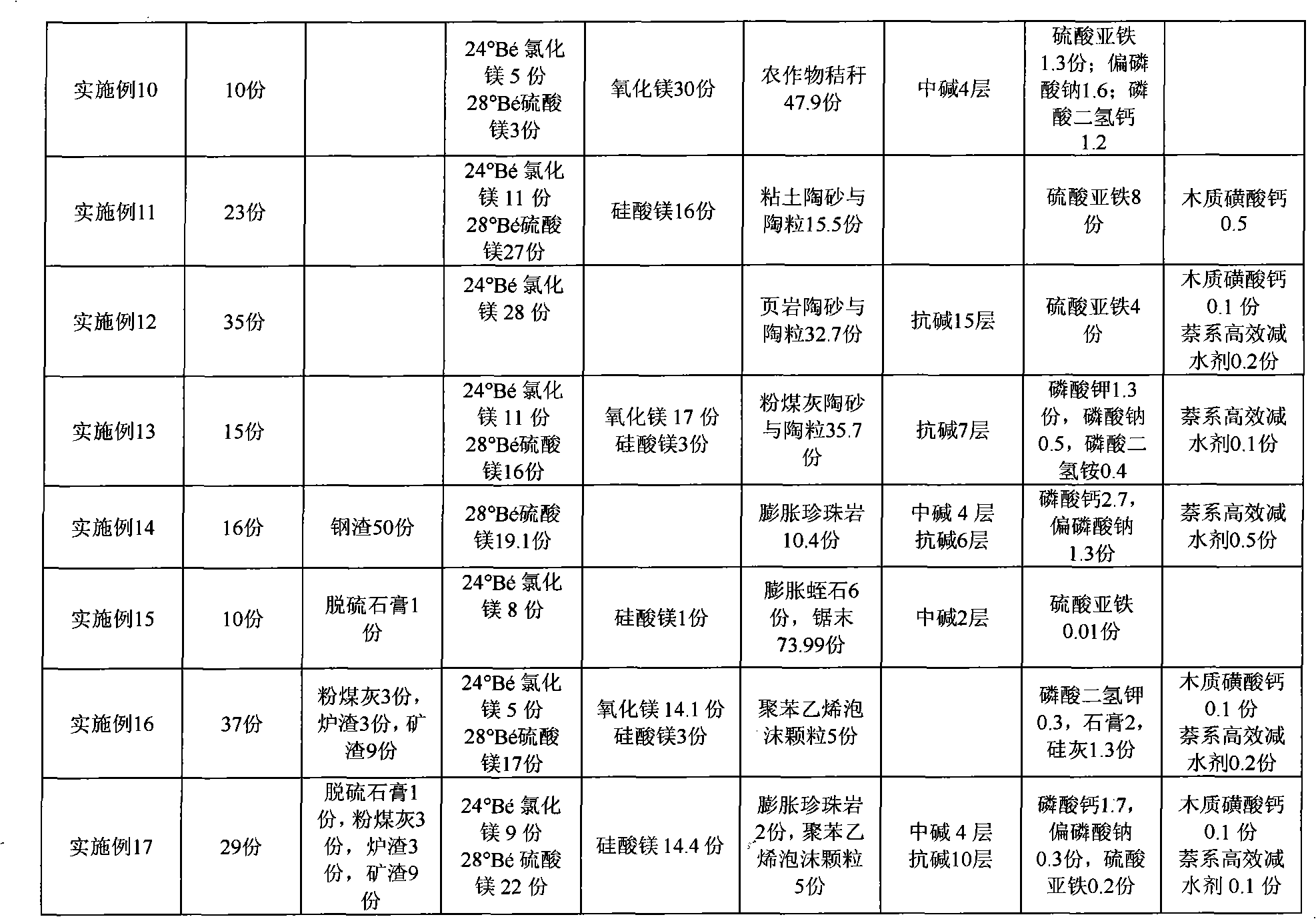

[0029] (1) Raw material measurement: lightly burned dolomite powder, industrial waste residue, blending agent solution, thickener, aggregate, water-resistant additive, and water-reducing agent were measured according to the mixing ratio of Examples 2-9;

[0030] (2) mixing and stirring: the measured raw materials are mixed evenly, and stirred to make a lightly burned dolomite mixture;

[0031] (3) Pouring molding: inject the lightly burned dolomite mixture into the mold to make a solid or hollow cross-sectional shape. During the pouring process, the glass fiber mesh cloth needs to be evenly spread on the upper and lower surfaces of the 3-20mm slurry middle;

[0032] (4) Natural maintenance: After the light-burned dolomite lightweight partition wall panels are cured, they are demoulded, stacked, and maintained under natural ...

Embodiment 18

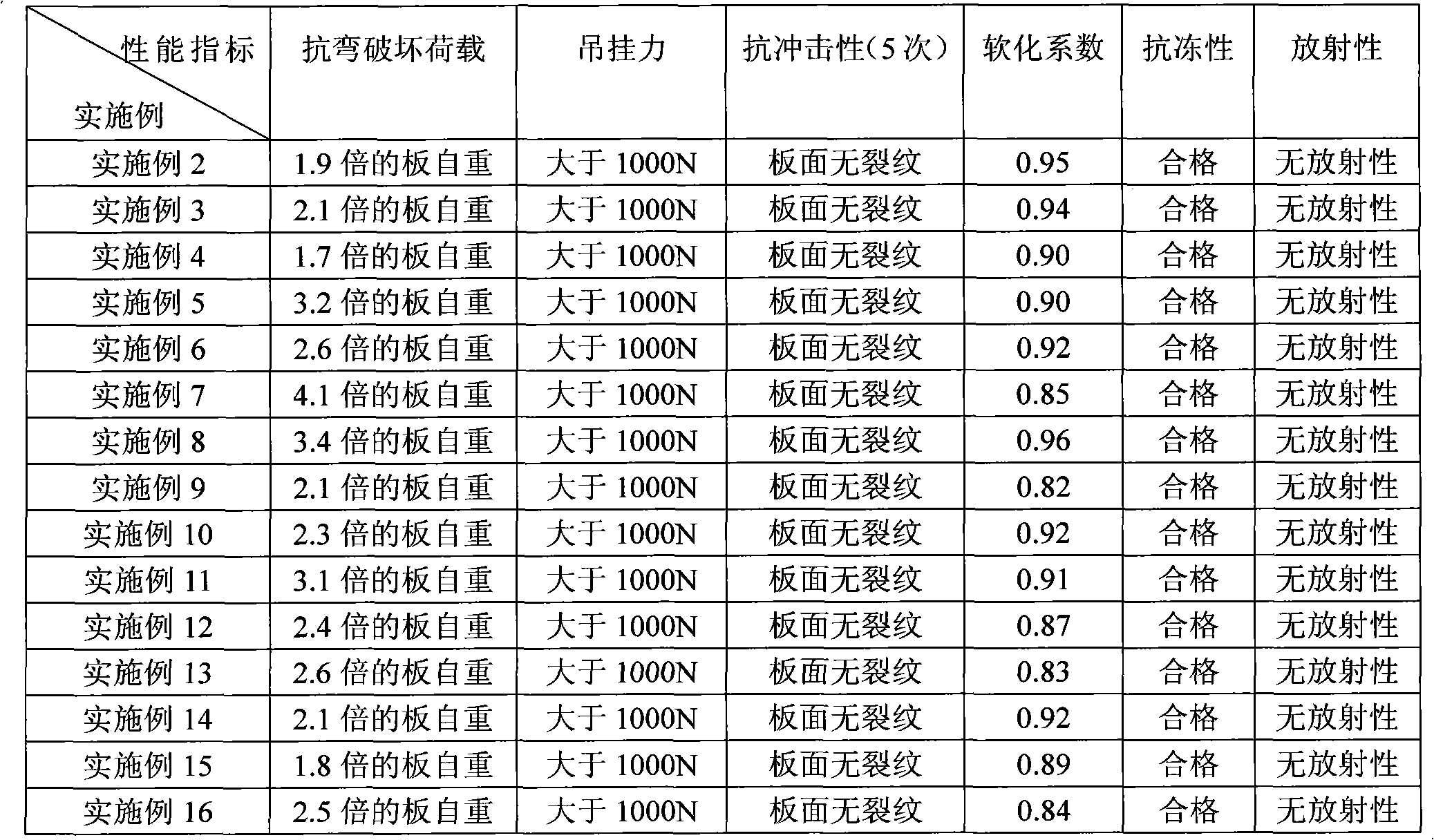

[0038] Example 18: The properties of the light-burned dolomite lightweight partition wall board prepared by the formula of Examples 2-17 were tested, and the results are shown in Table 2.

[0039] Table 2: Performance test table of the light-burned dolomite lightweight partition wall board prepared by the formula of Example 2-17

[0040]

[0041]

[0042] From the data in Table 2, it can be seen that the present invention has the characteristics of light weight, high strength, water resistance, frost resistance, impact resistance, and environmental protection requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com