Ardealite premixed dry-mixed mortar capable of being used for 3D printing

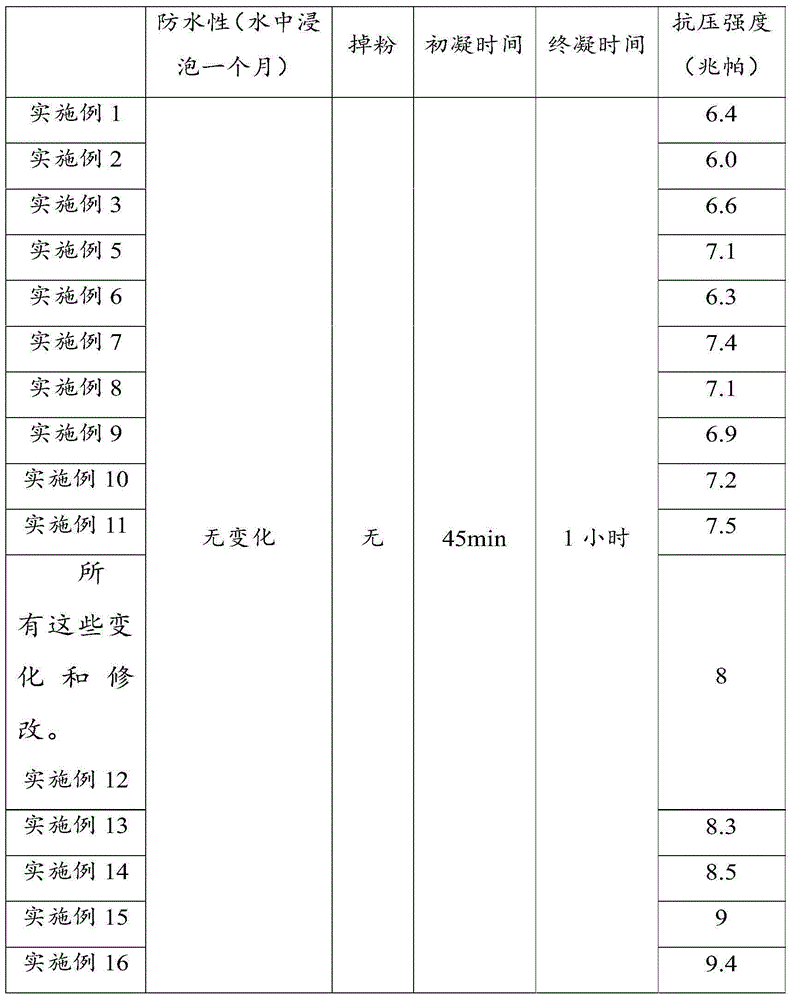

A dry-mixed mortar and 3D printing technology, applied in the field of mortar, can solve the problems of physical and chemical parameters such as viscosity, initial setting, and final setting time not meeting the requirements, unable to apply 3D printing robots, and unable to load-bearing walls, etc., to extend the construction time Time, high strength, good effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A phosphogypsum ready-mixed dry-mixed mortar that can be used for 3D printing includes: by weight, 500 parts of dihydrate gypsum, 400 parts of aggregate, 30 parts of coal ash, and redispersible latex powder (neutral and flexible at a ratio of 1:2 Weight ratio mixing) 0.2 part, k-120.2 part, melamine 1 part, viscosity is 0.5 part of cellulose ether of 200,000 units.

Embodiment 2

[0051] A phosphogypsum ready-mixed dry-mixed mortar that can be used for 3D printing includes: by weight, 600 parts of dihydrate gypsum, 500 parts of aggregate, 50 parts of coal ash, and redispersible latex powder (neutral and flexible at a ratio of 1:2 Weight ratio mixing) 0.8 part, k-120.3 part, melamine 1.5 part, viscosity is 0.7 part of cellulose ether of 200,000 units.

Embodiment 3

[0053] A phosphogypsum ready-mixed dry-mixed mortar that can be used for 3D printing includes: by weight, 500 parts of dihydrate gypsum, 400 parts of aggregate, 30 parts of coal ash, and redispersible latex powder (neutral and flexible at a ratio of 1:2 Weight ratio mixing) 0.5 part, k-120.2 part, melamine 1.3 part, viscosity is 0.6 part of cellulose ether of 200,000 units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com