Load bearing wall formwork system and method

a technology of bearing walls and formwork, applied in the field of concrete forming structures and bearing walls, ceilings and floors, can solve the problems of time-consuming and costly assembly of the complete structure, the disadvantages of the foregoing system, and the inability to meet the requirements of the complete structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

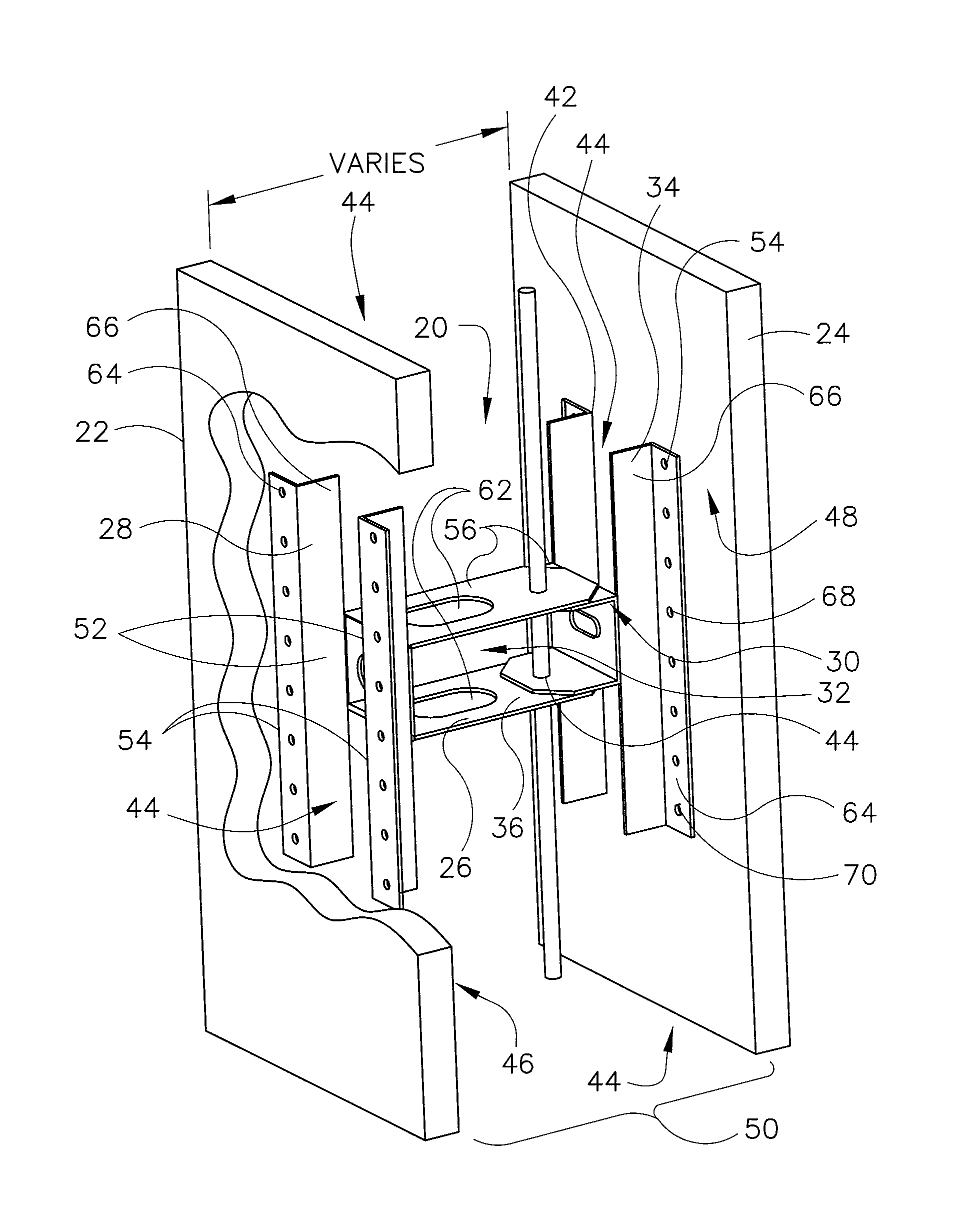

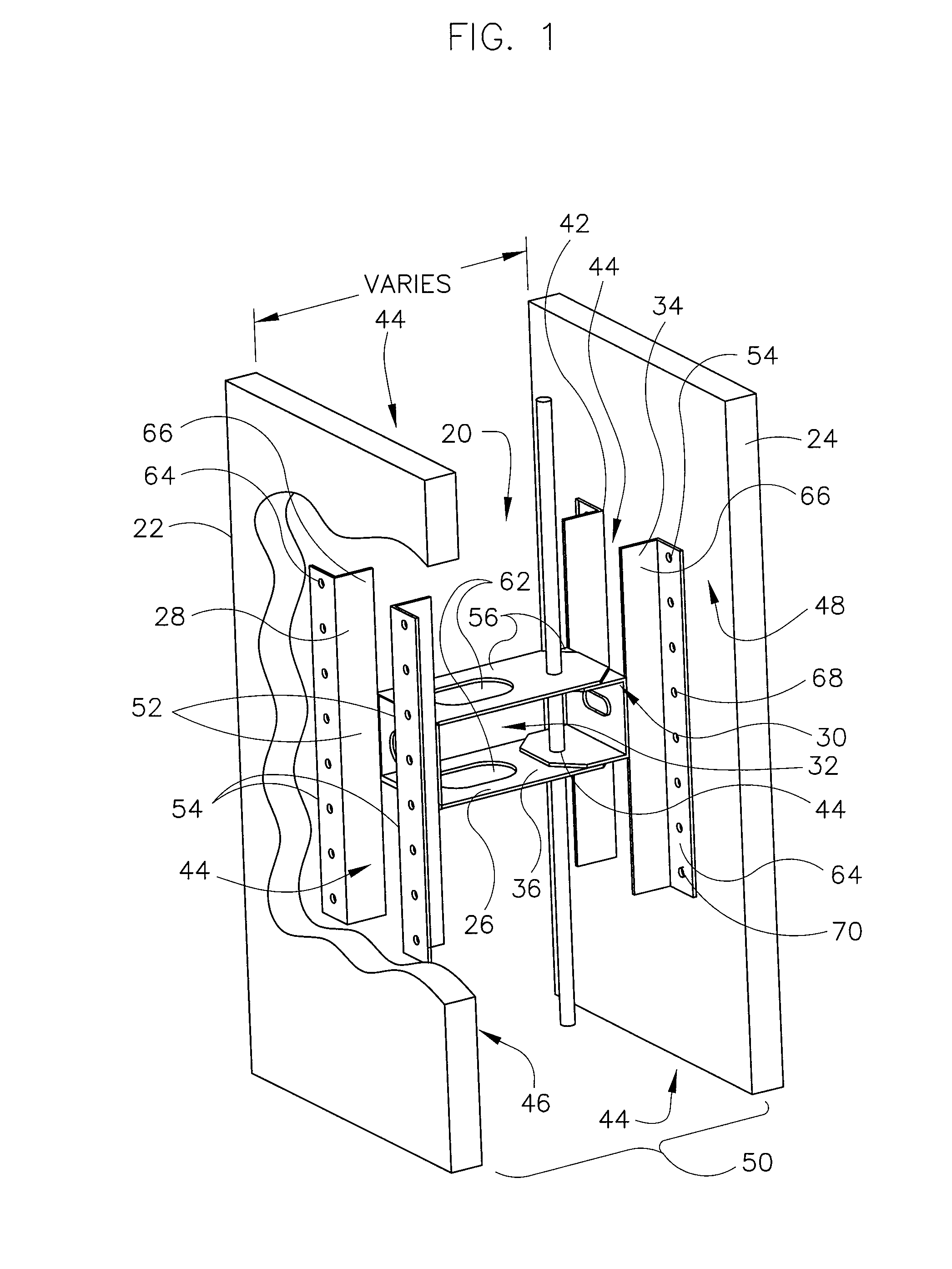

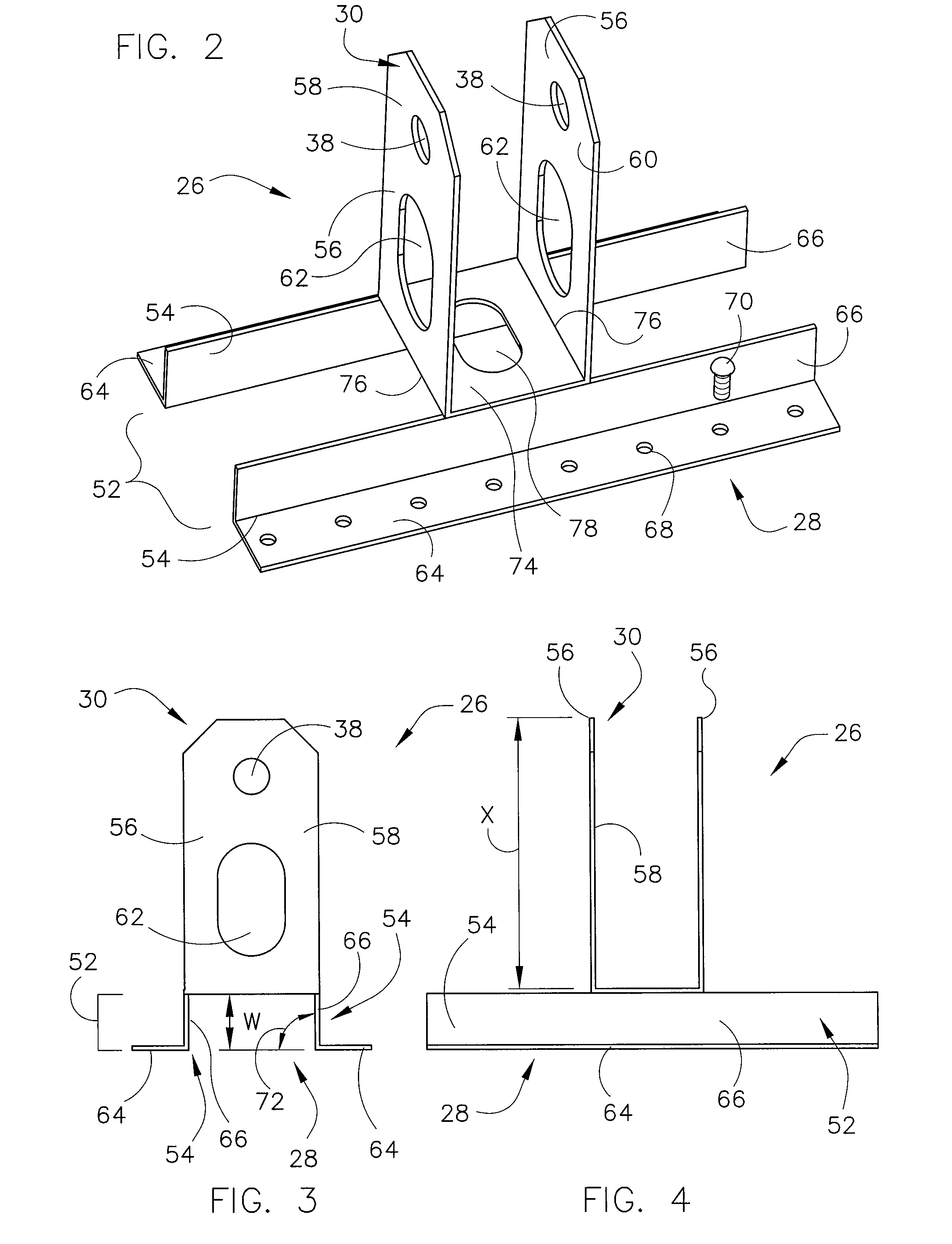

[0035]As can be seen from the Figures, a clip assembly 20 for joining two or more substantially planar structures or wall panels is provided. While “wall” is used for purposes of discuss herein, the system and assembly may be applied to walls, floors, ceilings, or other supporting structures. Likewise, while “panel” and “planar structure” are used herein, any board or like structure may be substituted in place of same.

[0036]Specifically, a clip assembly 20 for joining two or more panels 22, 24 in a spaced apart manner is disclosed. As can be seen in FIG. 1, the clip assembly 20 includes a first clip bracket 26, or member, that has a first side 28 for attaching to a panel 22 or 24 and a second side 30 opposite the first side. A second clip member 28 is also provided. The second clip member 28 or bracket, has a first side 34 for attachment to a second panel 24 and a second side 36 opposite the first side. The second clip member 28 is engageable with the first clip member 26. In a pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com