Foam concrete composite heat preservation wall body with concrete blocks and construction method thereof

A technology of concrete blocks, foam concrete, applied in the direction of insulation, walls, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

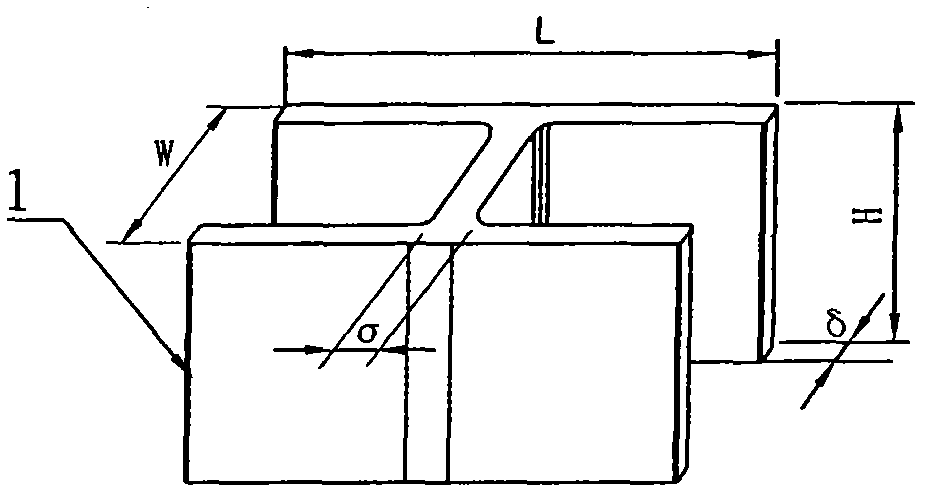

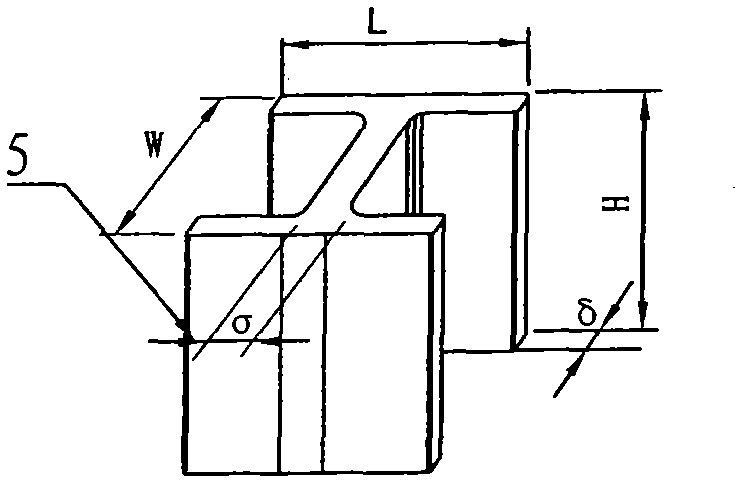

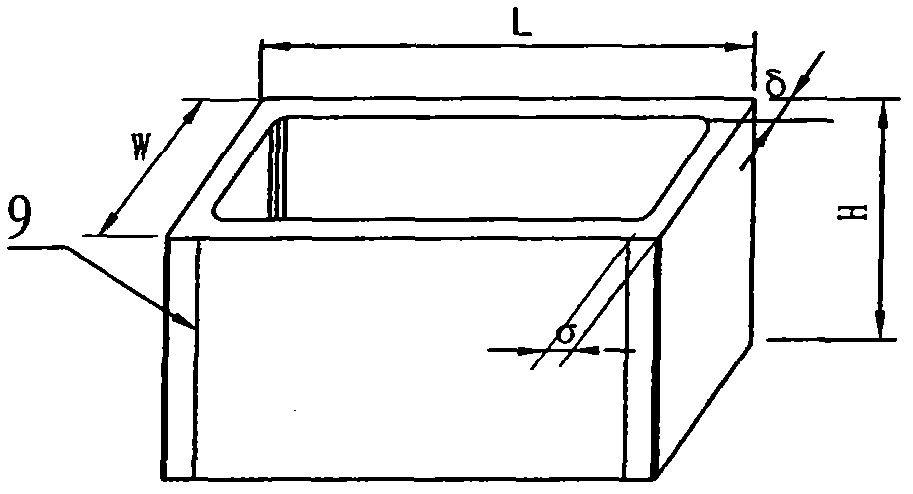

[0103] The target building is a 120m 2 The single-storey farmhouse is 15m long, 8m wide, and the front eaves are 1.3m wide. There is a solid wall and a beam in the room. There is a doorway and two windows on the front wall of the house, and two small ventilation windows on the back wall. Before construction, the building foundation and ground ring beams have been completed and have met the requirements of the next construction. The wall thickness is 240mm, so concrete blocks with W=200mm are used.

[0104] 1. According to the design positions of doorways, windows and beams, use H-shaped concrete blocks 1, rectangular hollow concrete blocks 9, small H-shaped concrete blocks 5 and cement mortar 25. Image 6 , Figure 7 , Figure 8 The front wall, back wall, side walls on both sides of the masonry house, T-shaped wall and 90° corner wall. press Figure 13 ~ Figure 18 , Construction of the electrical control cabinet 30, power switch 41, and socket 44 designed on the wall. Specifi...

Embodiment 2

[0115] The construction building is a 360m 2 The foundation of the three-story building has been completed and has met the next construction requirements. The wall thickness of the first floor is 260mm, the second floor is 240mm, and the third floor is 220mm. Therefore, concrete blocks with W=240mm, W=220mm, and W=200mm are used in sequence.

[0116] 1. Set up column reinforcement 27 for pouring reinforced concrete columns on the foundation;

[0117] 2. Press Picture 9 , 11 , 12, use H-shaped concrete block 1, rectangular hollow concrete block 9, b-shaped concrete block 17, 匚-shaped concrete block 13 and cement mortar 25 to build the first floor wall of the building (including the word Front wall, back wall, side walls on both sides, T-shaped wall and 90° corner wall), specifically:

[0118] A font wall (such as Picture 9 Shown) The concrete block masonry of the bearing wall column cavities of the front wall, the back wall and the side walls on both sides, the left side of the fir...

Embodiment 3

[0132] Construction building is a 3000m 2 The foundation of the seven-story residential building has been completed and has reached the next construction requirements. The wall thickness of the first floor is 340mm, and the wall thickness of the seventh floor is reduced by 20mm every time the floor is raised. Therefore, the W value of the concrete blocks used on each floor is 20mm smaller than the wall thickness.

[0133] 1. Set up column reinforcement 27 for pouring reinforced concrete columns on the foundation.

[0134] 2. On the fourth and lower floors of the building, the straight front wall, back wall, and the load-bearing wall pillars on the side walls on both sides, such as Picture 10 As shown, on the first floor, an H-shaped concrete block 1 is built between the bearing wall column reinforcement 27, and then two rectangular hollow concrete blocks 9 are used to connect, or two square-shaped concrete blocks 13 sets Lay outside the load-bearing wall column reinforcement 27, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com