Production method for iron tailing sand aerated concrete building block

A technology of aerated concrete and iron tailings, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., and can solve the problems of suboptimal waste utilization, low gold tailings addition, and quicklime Large ratio and other problems, to achieve the effect of expanding the effective use area, easy to discharge moisture, and high waste utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

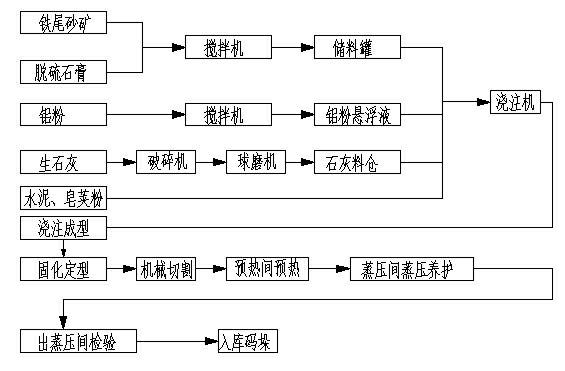

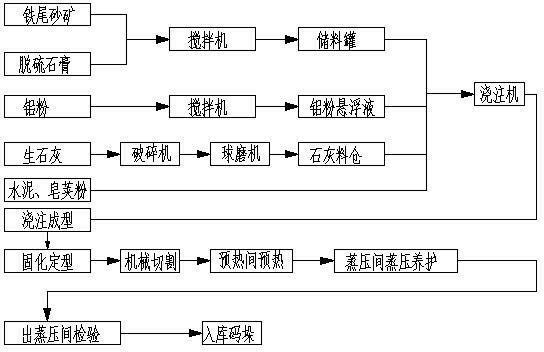

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] see figure 1 , the production method of the iron tailings aerated concrete block described in the present embodiment, it is main raw material with iron tailings, desulfurized gypsum, quicklime, cement, is auxiliary material production with aluminum powder, acacia powder, and its steps are as follows:

[0027] (1) Preparation of production raw materials:

[0028] ① Preparation of iron tailings mortar: The purchased iron tailings sand is transported to the raw material warehouse in the factory, and can be directly used in production without other processing procedures. The transport process of iron tailings from the receiving tank to the pulping machine adopts a closed belt conveyor; the desulfurized gypsum with a water content of 40% is stored in the raw material warehouse after entering the factory. According to the weight ratio (iron tailing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com