Network frame prefabricated composite board, sandwiched floor and its connection construction method

A construction method and sandwich wall technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of manual insertion of wire boards, disturbance of normal order, cracking of surface plastering, etc., to achieve fast construction and good hurricane resistance , Good effect of hurricane resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

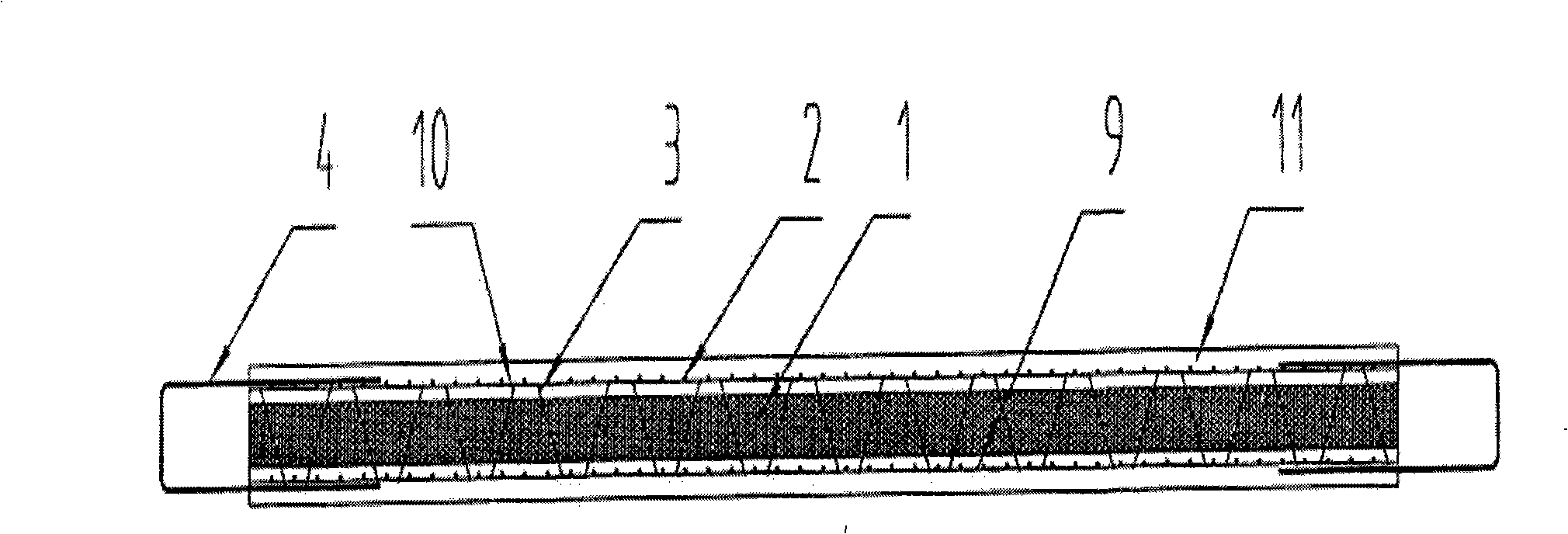

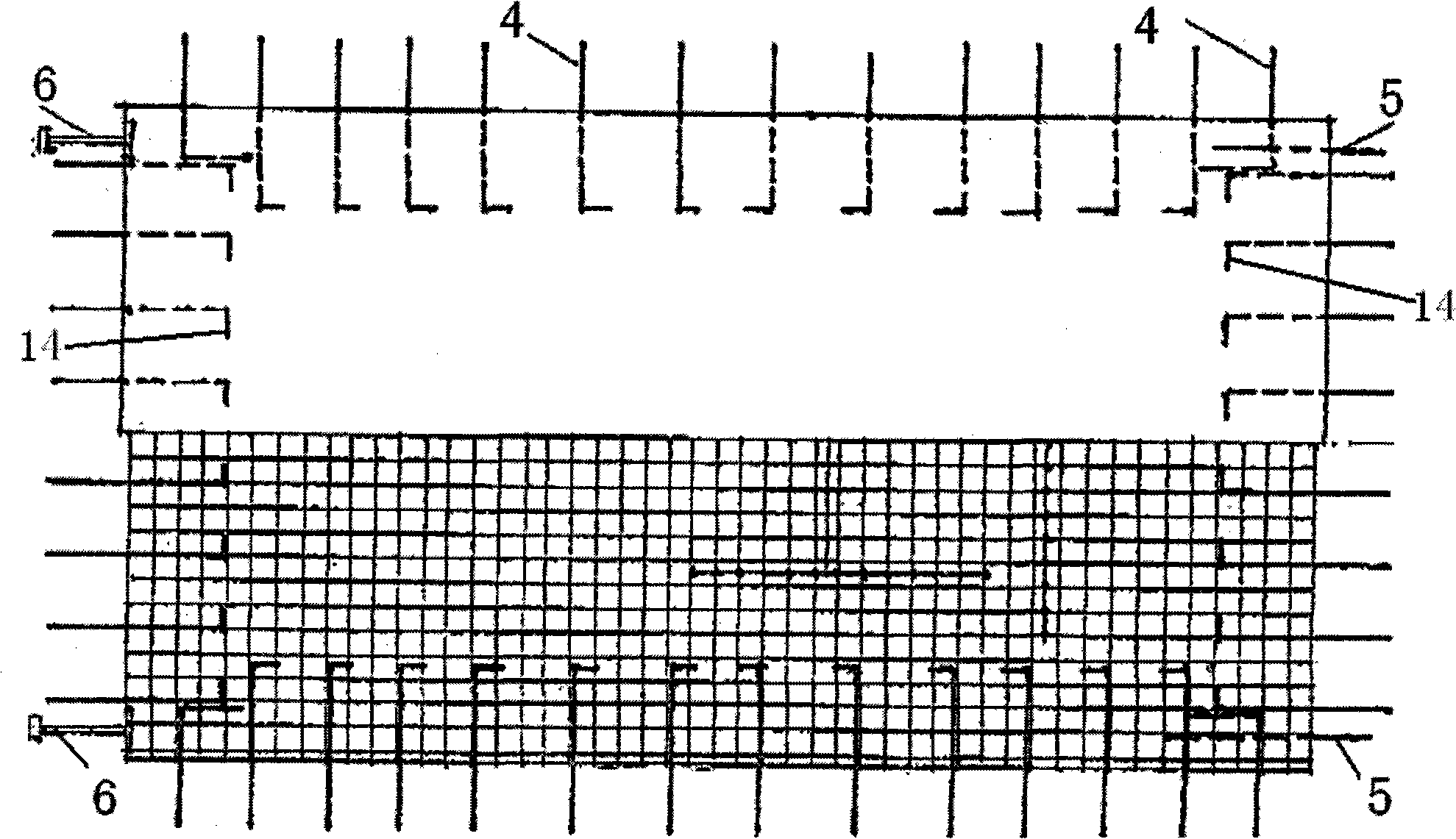

[0032] This example refers to figure 1 , 2 , 3, 4, prefabricated grid sandwich wall panels, including a core plate 1, the upper and lower sides of the core plate 1 are respectively provided with steel wire mesh 2, 9, the upper and lower steel wire mesh 2, 9 and the oblique ribs 3 passing through the core plate 1 , 10 are fixedly connected to form a three-dimensional space grid structure. U-shaped connecting reinforcement rings 4 are arranged on the outer sides of the upper and lower steel wire meshes 2, 9 and around the core plate 1, and the steel wire meshes 2, 9 and the core plate 1 are formed. The reinforced cement layer 11 covered by the steel wire mesh 2, 9 is poured; the steel wire mesh 2, 9 is welded by criss-cross steel wires; the U-shaped connecting steel ring 4 is a U-shaped structure with an opening in the middle of one end, The two ends of the U shape are fixedly connected to the transverse steel wires of the steel wire mesh 2 and 9, and the other end correspondin...

Embodiment 2

[0038] This example refers to figure 1 , 2 , 3, 5, the connection construction method of prefabricated grid sandwich wall panels parallel walls, including the following steps:

[0039] 1. At the construction site, connect the reinforcement rings 4 reserved around two adjacent sandwich panels in parallel;

[0040] 2. A fixed reinforcement ring 8 is added to the outside of the core board 1 of each sandwich panel for connection, and a reinforcement ring 7 is inserted into the fixed reinforcement ring 8 and the opposite reinforcement ring 4, and the connection is fixed with an iron wire;

[0041] 3. The load-bearing walls are connected by cast-in-place concrete columns.

Embodiment 3

[0043] This example refers to figure 1 , 2 , 3, 6, the connection construction method of the L-shaped wall of the prefabricated grid sandwich wall panel, including the following steps:

[0044] 1. At the construction site, vertically connect the reinforcement rings 4 reserved around two adjacent sandwich panels;

[0045] 2. A fixed reinforcement ring 12 is provided at the corner of the reinforcement ring 4 for connection, and a fixed reinforcement ring 8 is added to the outside of the core plate 1 of each sandwich panel for connection, and the fixed reinforcement rings 8, 12 and the buttressed reinforcement ring 4 Insert steel bar 7 in, fix and connect with iron wire;

[0046] 3. The load-bearing walls are connected by cast-in-place concrete columns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com