Cement-based decoration material, decoration plate and production method thereof

A decorative material and cement-based technology, applied in chemical instruments and methods, building structures, clay preparation equipment, etc., can solve the problems of high cost, falling off, thick decorative boards, etc., to reduce production costs and improve adhesion , The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In the present embodiment, the composition of cement-based decorative material is as follows:

[0057] Cement powder (label: 42.5 # ) 100 kg

[0058] Acrylic emulsion (A-106) 40 kg

[0059] Hydroxypropyl methylcellulose (HPMC) 0.1 kg

[0060] Manufacture a decorative panel with the above-mentioned components, comprising the following steps:

[0061] (1) After fully mixing the above components, mix them with 40 kg of water to prepare cement slurry for later use.

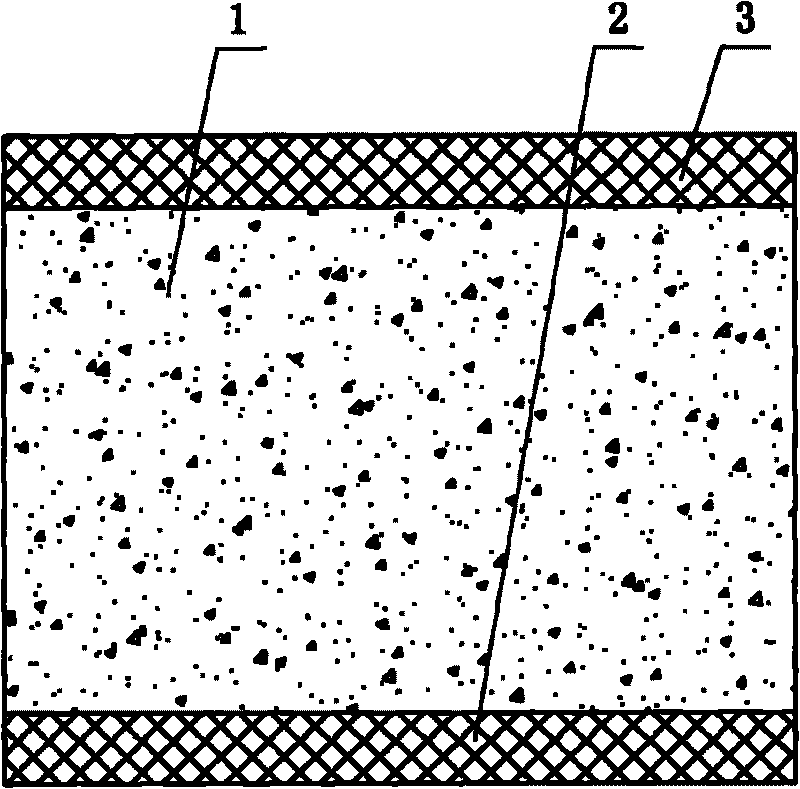

[0062] (2) Place the glass fiber mesh cloth and the bottom non-woven fabric in the transmission rolling equipment, and the two move forward under the traction of the transmission rolling equipment, and pour the cement slurry obtained in step (1) on the glass On the fiber mesh cloth and the bottom non-woven fabric, the upper and lower pressure rollers are evenly squeezed to make a semi-finished product.

[0063] (3) Transport the semi-finished product obtained in step (2) to the oven for drying. The drying ...

Embodiment 2

[0067] In the present embodiment, the composition of cement-based decorative material is as follows:

[0068] Cement powder (label: 32.5 # ) 100 kg

[0069] Elastic emulsion (S-07) and styrene-acrylic emulsion (S-01) (weight ratio 1: 100 kg

[0070] 0.3)

[0071] Polyanionic cellulose (PAC) 0.5 kg

[0072] Polyvinyl alcohol (molecular weight: 25000) 30 kg

[0073] Quartz sand 150 kg

[0074] Manufacture a decorative panel with the above-mentioned components, comprising the following steps:

[0075] (1) After fully mixing the above components, mix them with 175 kg of water, and prepare the cement slurry for later use.

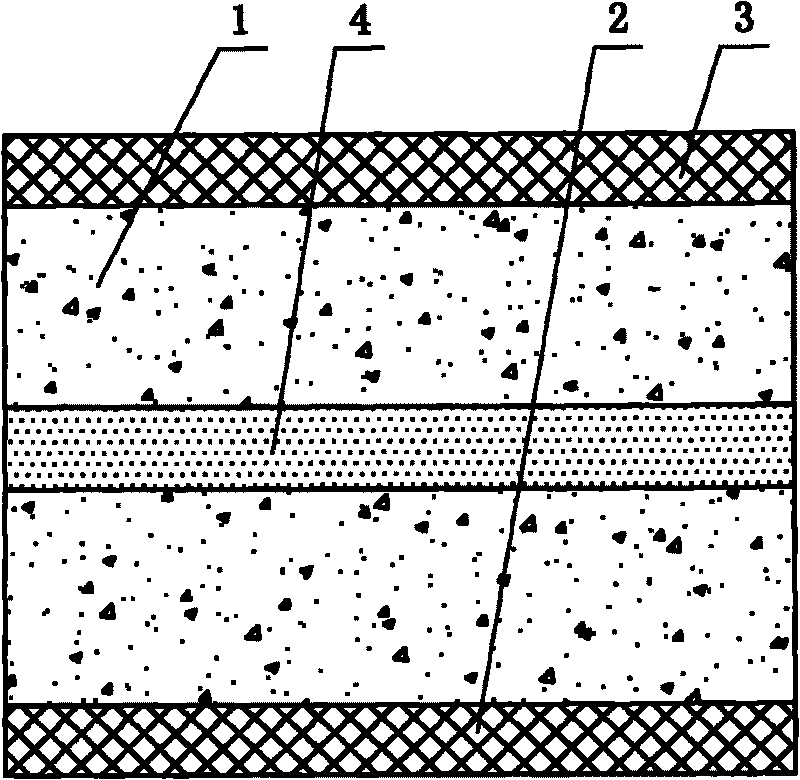

[0076] (2) Place the bottom non-woven fabric in the lower traction wheel of the transmission rolling equipment, place the surface non-woven fabric in the upper traction wheel of the transmission rolling equipment, and the two layers of cloth move forward under the traction of the transmission rolling equipment While advancing, the cement slurry obtained i...

Embodiment 3

[0081] In the present embodiment, the composition of cement-based decorative material is as follows:

[0082] Cement powder (label: 42.5 # ) 300 kg

[0083] HW-5115 6kg

[0084] Hydroxyethyl cellulose ether (HEC) 1.2 kg

[0085] Polyvinyl alcohol (molecular weight: 45000) 60 kg

[0086] 150kg river sand

[0087] Di-isooctyl phthalate 1.2 kg

[0088] Manufacture a decorative panel with the above-mentioned components, comprising the following steps:

[0089] (1) After fully mixing the above components, mix them with 512.4 kg of water, and prepare the cement slurry for subsequent use.

[0090] (2) Place the glass fiber mesh cloth and the bottom non-woven fabric in the lower traction wheel of the transmission rolling equipment, and place the surface non-woven fabric in the upper traction wheel of the transmission rolling equipment, and the three-layer cloth is placed in the transmission rolling equipment. It moves forward under the traction of the equipment, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com