Environmentally-friendly low-smoke halogen-free flame-retardant photovoltaic cable insulation and sheath and preparation method thereof

A photovoltaic cable, an environmentally friendly technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

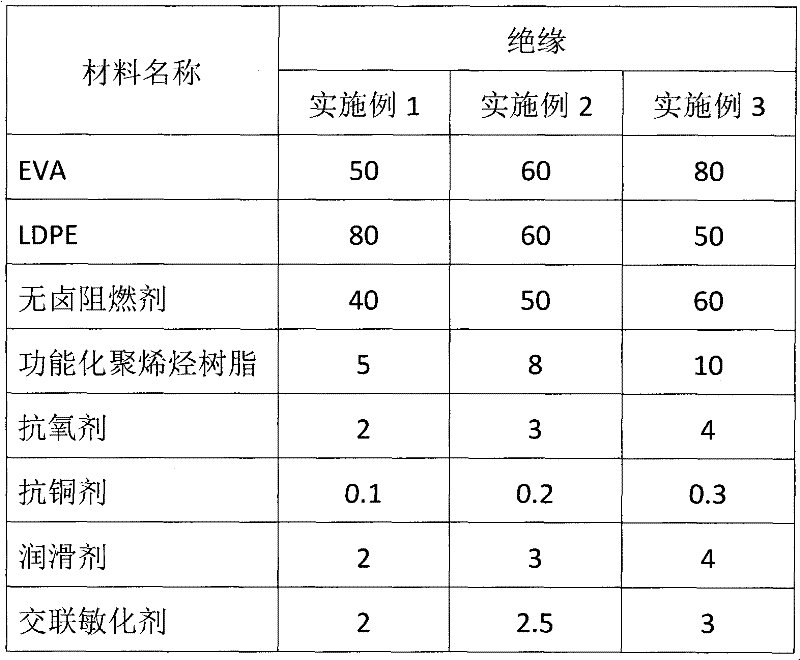

[0024] See the following table for the weight ratio of each component of the environmentally friendly low-smoke halogen-free flame-retardant photovoltaic cable insulation and sheath:

[0025] See the following table for the weight ratio of each component of the environmentally friendly low-smoke halogen-free flame-retardant photovoltaic cable insulation:

[0026]

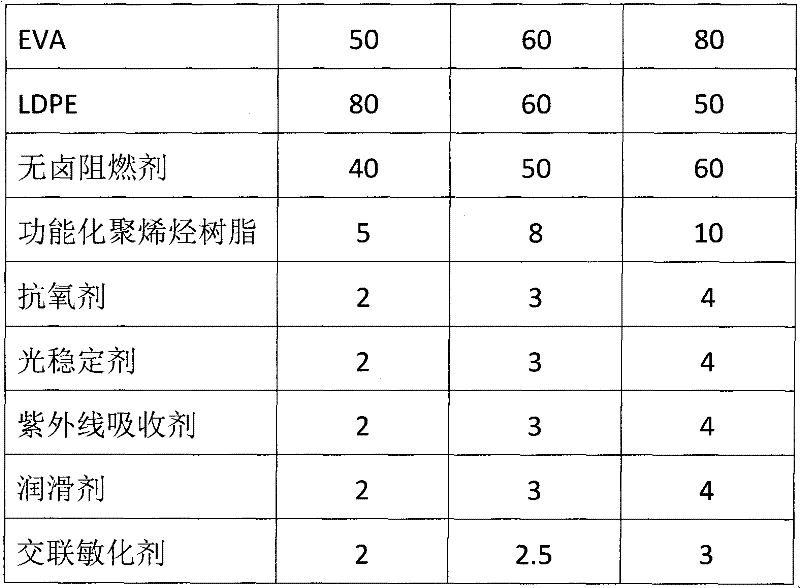

[0027] See the following table for the weight ratio of each component of the environmentally friendly low-smoke halogen-free flame-retardant photovoltaic cable sheath:

[0028]

[0029]

[0030] Preparation:

[0031] (1) Accurately weigh various base materials according to the above weight ratio: EVA, LDPE, halogen-free flame retardant, functionalized polyolefin resin, antioxidant, anti-copper agent, lubricant, ultraviolet absorber, light stabilizer agent and cross-linking sensitizer, add the above weighed base material into the high-speed kneader at one time, the heating temperature is 60-80°C, knead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com