Semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material and preparation method thereof

A polyolefin sheath, semi-conductive technology, applied in the direction of conductive materials, conductors, circuits, etc. dispersed in non-conductive inorganic materials, can solve the problems of influence, high cost of sheath material raw materials, difficult processing, etc., and achieve excellent processing performance, production cost reduction, excellent electrical conductivity and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

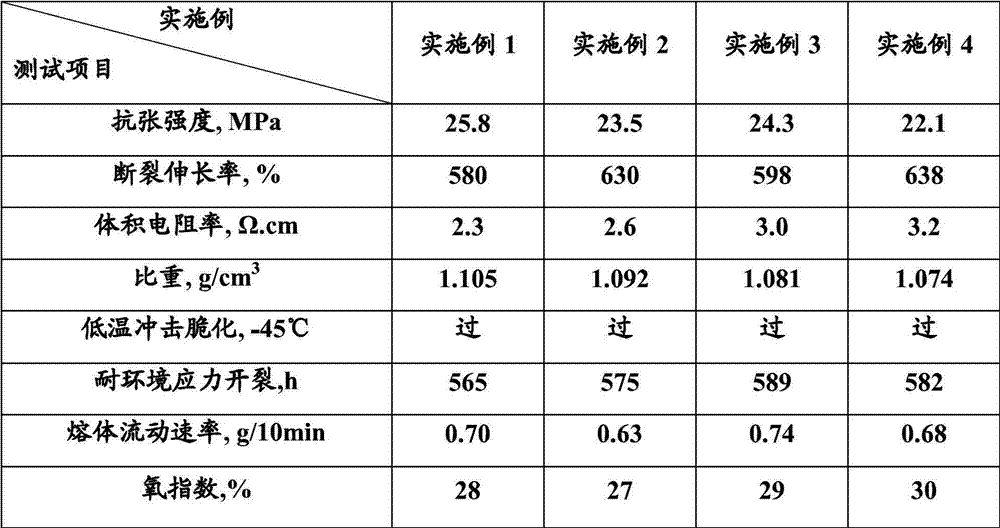

Examples

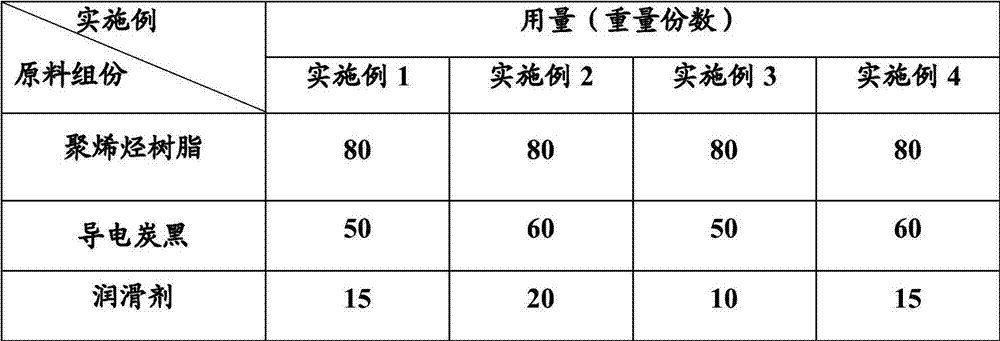

Embodiment 1

[0030] This embodiment provides a special semi-conductive polyolefin sheath material for ultra-high voltage cables. The raw materials used are as follows:

[0031] Polyolefin resin: EVA (VA content is 25wt%-40wt%, melt flow rate is 4.6g / (10min, 2.16kg)) and LDPE (DJ210 brand) is composed of 2:1 by mass ratio;

[0032] Conductive carbon black: super conductive carbon black JE6900;

[0033] Lubricant: polyethylene wax (polymer wax);

[0034] Wetting agent: 10# white oil;

[0035] Dispersant: oleic acid amide;

[0036] Antioxidant: thiobisphenol antioxidant 300#, thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, tris[2.4-di-tert A compound system of butylphenyl] phosphite and 2,2,4-trimethyl-1,2-dihydroquinoline polymer, the weight ratio of the four is 1.5:1.5:2:1;

[0037] Anti-ultraviolet agent: 2-hydroxy-4-n-octyloxybenzophenone;

[0038] Flame retardant: a combination of magnesium hydroxide and aluminum hydroxide, the mass ratio of the two is 2:1;

[0039] Stearate: a c...

Embodiment 2

[0045] This embodiment provides a special semi-conductive polyolefin sheath material for ultra-high voltage cables. The raw materials used are as follows:

[0046] Polyolefin resin: EVA (VA content is 25wt%-40wt%, melt flow rate is 4.6g / (10min, 2.16kg));

[0047] Conductive carbon black: a mixture of super conductive carbon black JE6900 and conductive carbon black VXC200, the ratio of the two is 2:1;

[0048] Lubricant: polyethylene wax and fluorine-containing rheological agent compound, the ratio of the two is 1:1;

[0049] Wetting agent: dimethyl silicone oil;

[0050] Dispersant: compound of oleic acid amide and erucic acid amide, the ratio of the two is 2:1;

[0051] Antioxidant: thiobisphenol antioxidant 300#, thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, tris[2.4-di-tert A compound system of butylphenyl] phosphite and 2,2,4-trimethyl-1,2-dihydroquinoline polymer, the weight ratio of the four is 1.5:1.5:2:1;

[0052] Anti-ultraviolet agent: 2-hydroxy-4-n-octyl...

Embodiment 3

[0060] This embodiment provides a special semi-conductive polyolefin sheath material for ultra-high voltage cables. The raw materials used are as follows:

[0061] Polyolefin resin: EVA (VA content is 25wt%-40wt%, melt flow rate is 4.6g / (10min, 2.16kg)) and LDPE (DJ210 brand, melt flow rate is 2.0g / (10min, 2.16kg) ) It is constituted by mass ratio 1:1;

[0062] Conductive carbon black: super conductive carbon black JE6900;

[0063] Lubricant: polyethylene wax;

[0064] Wetting agent: dimethyl silicone oil;

[0065] Dispersant: compound of oleic acid amide and erucic acid amide, the ratio of the two is 2:1;

[0066] Antioxidant: thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, tetra[methyl-β-(3,5-di-tert-butyl- 4-hydroxyphenyl) propionate] pentaerythritol ester, tris[2.4-di-tert-butylphenyl] phosphite and 2,2,4-trimethyl-1,2-dihydroquinoline polymer compound Matching system, the weight ratio of the four is 1:1:2:1;

[0067] Anti-ultraviolet agent: 2-hydroxy-4-n-octyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com