Weatherproof low-smoke zero-halogen polyolefin sheath material for extra-high-tension cable and preparation method of weatherproof low-smoke zero-halogen polyolefin sheath material

A polyolefin sheath, ultra-high voltage technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of harmfulness to the human body, low smoke transmission rate, blocking the escape line of sight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

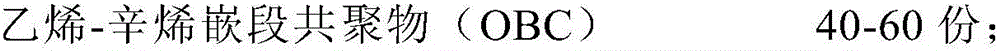

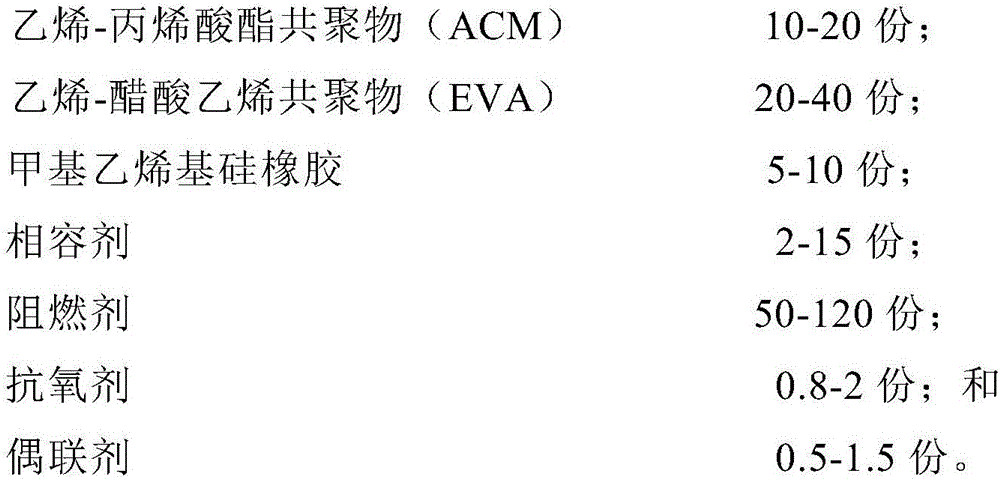

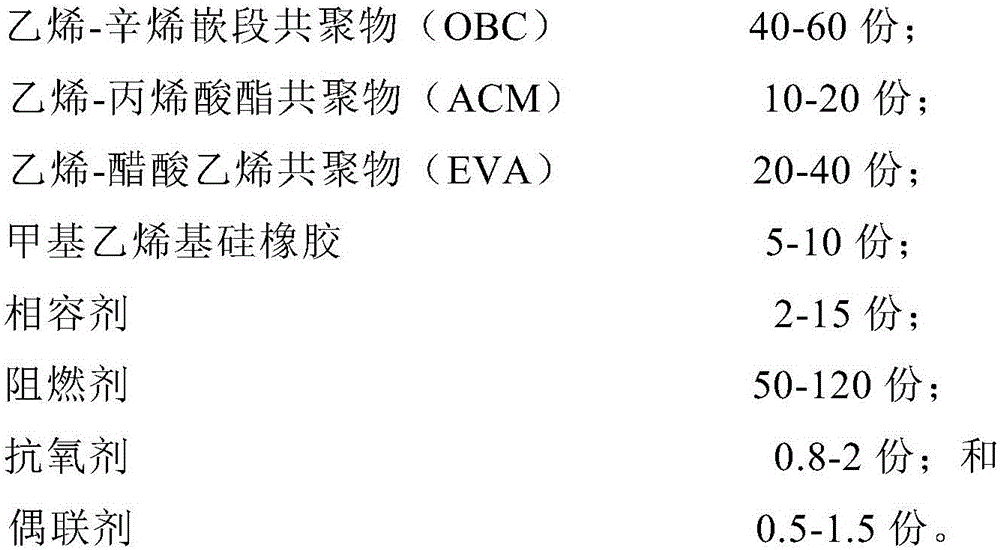

Method used

Image

Examples

Embodiment 1-7

[0083] Preparation of sheathing material

[0084] According to the ratio in Table 1, the raw material components were weighed respectively, placed in a high-speed mixer and mixed for 4-8 minutes, and then the mixture was plasticized and kneaded in the twin-screw, and then entered into the single-screw extruder for granulation; the processing temperature of the twin-screw For: conveying section 125-135°C, melting section 125-135°C, mixing section 135-145°C, exhaust section 130-145°C, homogenizing section 145-155°C, head 150-160°C; single screw temperature It is: 140-150°C in the first zone, 140-155°C in the second zone, 150-160°C in the third zone, 155-165°C in the machine head, diced and air-cooled and packaged, and the experiment number is 1#-7# Sheath material.

[0085] Table 1

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com