Irradiation cross-linking low-smoke zero-halogen high flame-retarding polyolefin insulation material and preparing method thereof

A high flame retardant, polyolefin technology, used in insulated conductors, insulated cables, organic insulators, etc., can solve problems such as difficult combustion performance and poor processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

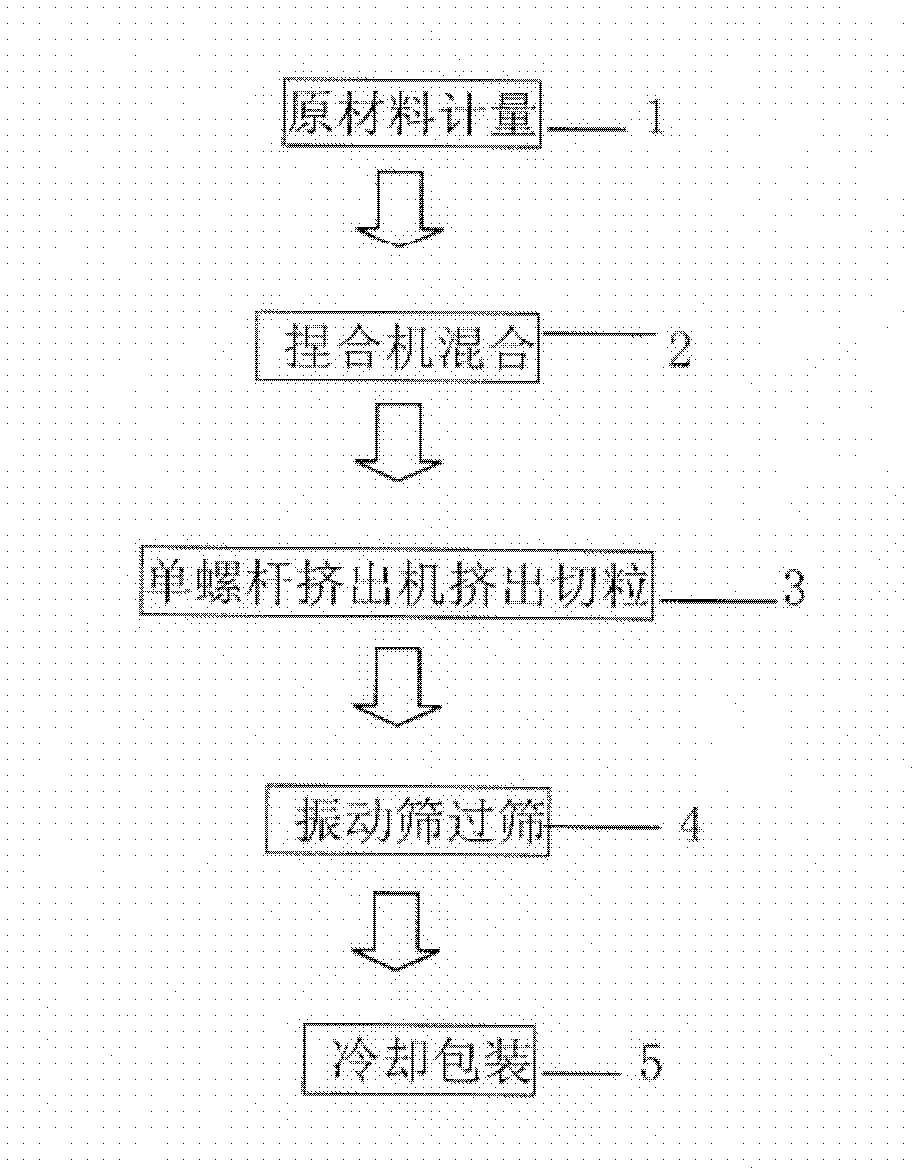

[0023] Combine figure 1 The embodiments and the embodiments further specifically describe the present invention, but are not limited thereto. The raw materials used in the following examples are all commercially available industrial products.

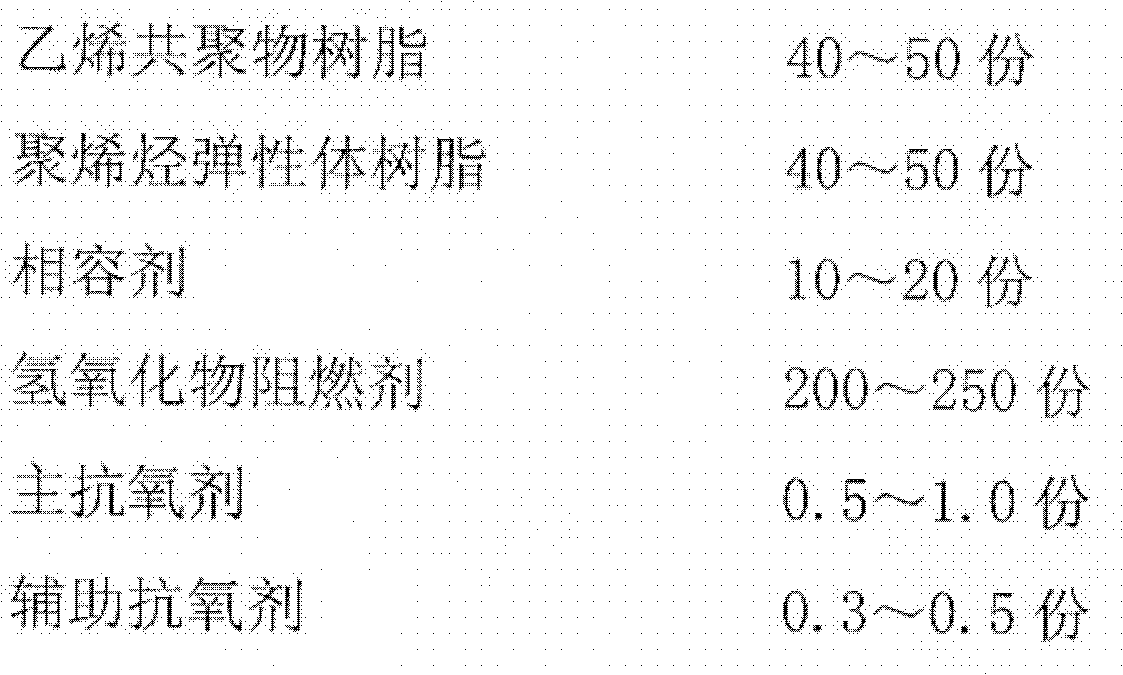

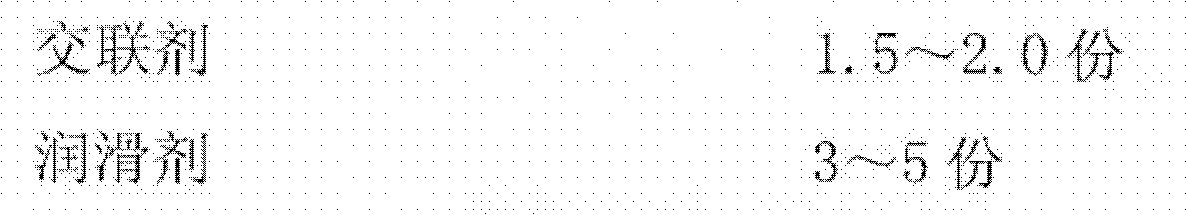

[0024] Examples 1 to 2 were prepared according to the weight parts shown in Table 2:

[0025] Table 2

[0026] Item

Example 1

Example 2

Ethylene-vinyl acetate copolymer

50

50

Polyolefin elastomer resin

50

50

Compatibilizer

20

20

Flame retardant

225

250

0.5

0.5

0.5

0.5

Crosslinking agent

1.5

1.5

[0027] Lubricant

5

5

Total

352.5

377.5

[0028] Preparation:

[0029] For the radiation crosslinked low-smoke, halogen-free, high-flame retardant polyolefin insulating material, the materials in the raw material formula are prepared according to their respective weight parts, and the raw materials are measured 1 after being mixed by a kneader 2. The mixing te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com