Easily-processed low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation and application thereof

An easy-to-process, heat-shrinkable technology, used in applications, household appliances, tubular items, etc., can solve the problems of difficult to accurately weigh and add, increase production input costs, and complicate the manufacturing process, to speed up extrusion and facilitate printing. The effect of permanently maintaining and reducing threats to personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

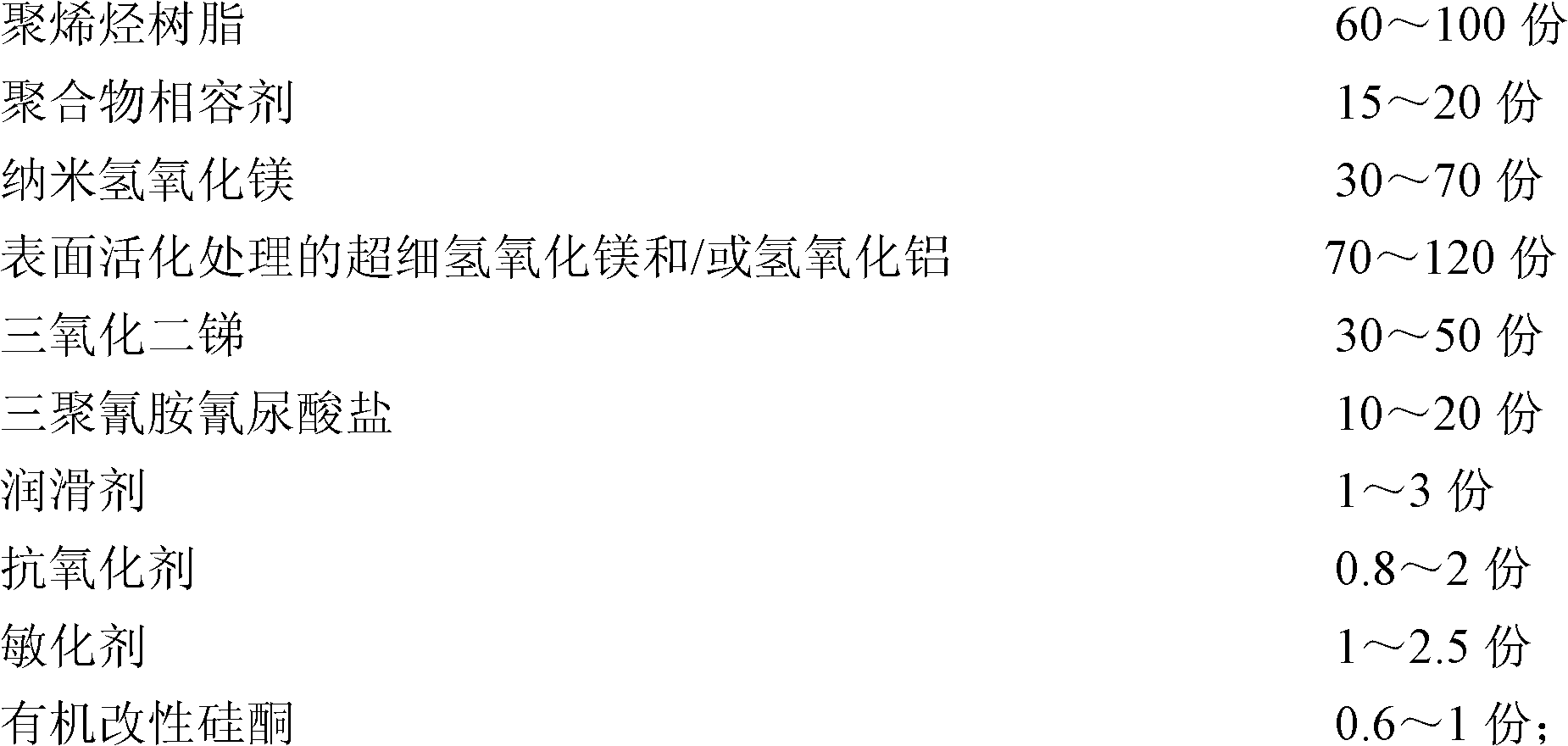

Method used

Image

Examples

Embodiment 1

[0052] (1) get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 14% quality, melt index is 3.5g / 10min, Mitsui Group of Japan, trade mark is P1405) 30kg, low density polyethylene (model 1I2A -1, produced by Beijing Yanshan Petrochemical) 40kg, ethylene-octene copolymer (model vistamaxx6102, Exxon Mobil) 30kg, maleic anhydride copolymerized modified ethylene-vinyl acetate copolymer (grafting rate 1.2%, melt The body index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., the brand is JCP-851) 20kg, 0.5kg antioxidant 1010, bis (2,6-di-tert-butyl-4-methylbenzene) pentaerythritol 1.5 kg of diphosphite and 1 kg of polyester graft modified silicone additives (the brand is H-Si 6440P, and the consumption is 0.26%) are successively dropped into the mixing chamber of the single-screw banburying granulator at 120° C. Refining for 4min; then adding nano-magnesium hydroxide (U.S. Albemarle, trade name H10) 70kg, superfine aluminum hydroxide (U.S. Alb...

Embodiment 2

[0056] (1) get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, French Atofina company, trade mark is EVAtane 2803) 30kg, linear low density Polyethylene (brand name 218-W, Saudi Basic Industries Corporation) 10kg, ethylene-octene copolymer 25kg, maleic anhydride copolymerized modified ethylene-vinyl acetate copolymer (graft rate 1.2%, melt index is 1.1 g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., the brand is JCP-851) 15kg, 0.5kg antioxidant 1076, dioctadecyl pentaerythritol bisphosphite 1kg and 0.6kg polyester graft modified silicone Auxiliary agent (brand is H-Si 6440P, consumption is 0.23%) puts into the mixing room of single-screw banburying granulator successively and banburying 4min under 120 ℃; H10) 50kg, superfine magnesium hydroxide (American Albemarle, brand H5IV) 70kg, antimony trioxide 40kg, melamine cyanurate 10kg and polyethylene wax 2kg banburying at 120°C for 6min; Then add 1.5 ...

Embodiment 3

[0060] (1) get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, and France Atofina company, trade mark is EVAtane 2803) 25kg, low-density polymer Ethylene 15kg, ethylene-octene copolymer 20kg, maleic anhydride copolymerized modified ethylene-vinyl acetate copolymer (graft rate 1.2%, melt index 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd. , brand name is JCP-851) 20kg, 0.3kg antioxidant 1010, bis(2,6-di-tert-butyl-4-methylbenzene) pentaerythritol diphosphite 0.5kg and 0.7kg polyester graft modified silicon The ketone additive (brand name is H-Si 6440P, consumption is 0.28%) is put into the mixing chamber of single-screw banburying granulator successively and banburying 4min under 120 ℃; Then add nano-magnesium hydroxide (American Yabao, The grade is H10) 30kg, superfine aluminum hydroxide (USA Albemarle, grade 104IO) 90kg, antimony trioxide 30kg, melamine cyanurate 20kg and zinc stearate 1kg ban...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal shock | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com