Flame-retardant and fire-resistant optical cable

A flame-retardant and fire-resistant fiber optic cable technology, which is applied in the field of optical communication transmission, can solve problems such as unreasonable structural settings, difficulty in meeting low-smoke performance, unsatisfactory flame-retardant and fire-resistant performance, etc., to ensure light flux, high strength and rigidity , Improve the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

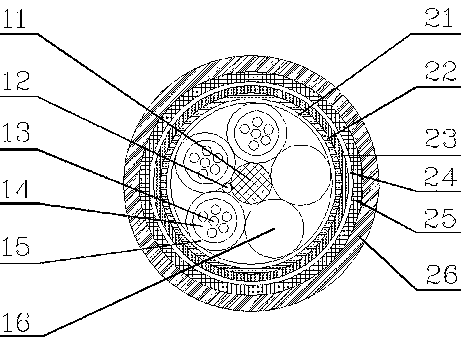

[0025] The first example is figure 1 As shown, it is a layer-stranded single-sheath single-armored flame-retardant and fire-resistant optical cable, which includes a layer-stranded cable core located in the center of the cable. The layer-stranded cable core includes a glass fiber central reinforcement 11, a glass fiber A loose tube 15 is stranded on the outer periphery of the fiber central reinforcement, and a filling rope 16 and a water blocking member 12 can also be twisted. An optical fiber unit 13 is laid inside the loose tube, and the optical fiber unit is an optical fiber, an optical fiber bundle or an optical fiber ribbon. The loose tube contains a water-blocking element 14, which is water-blocking yarn or water-blocking powder, forming a fully dry layer twisted cable core. The cable core is covered with an inner water-blocking layer 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com